I’ve been reloading for nearly thirty years. In that time I’ve learned a few lessons … most of them the hard way. I’m going to share a few things I’ve learned. If you are just getting into reloading, some of these tips will keep you out of trouble. But, even experienced reloaders are likely to find something new here. So without further ado, here are 10 reloading tips.

1. Everyone Has Room To Reload

Even if you live in an apartment the size of a phone booth, you have room to reload ammunition. My current home is comfortably sized, but it is far from being a mansion. Even though I have a good-sized basement, real estate down there is precious. My basement has to accommodate my office as well as a shop big enough to build flintlock rifles, and a photo and video studio. When I moved here I really struggled as to where I’d put a reloading bench. My solution was to build a bench under the cellar stairs. I call it the Harry Potter bench, and it works like a charm.

Advertisement — Continue Reading Below

- RELATED STORY: 6 Tips For Cleaning Your Rifle Bore

That bench only measures three feet by three feet, but by using a bench plate, I can maximize the bench top real estate. Bench plates are made several companies, with Lee Precision and Inline Fabrication having a couple of the best known example. They consist of two parts; a steel base plate that you mount to your bench, and a steel plate that you attach to the base of each of your presses and accessories. The base attached to the press slides into the plate on the bench and you lock it down. When you’re done with it, you pull off that piece of gear and replace it with another one mounted on another plate. With the plate system I can swap out any of my three reloading presses in the same spot, or I can use the plate to mount a case trimmer or one of my bullet sizers.

A bench like mine can easily be built in the hall closet of a small apartment, but, if even that is more room than you can spare, you can use a portable reloading stand. Several manufactures build these. I like Frankfort Arsenal’s. It is foldable, and can store away in very limited space. And, if even that is too big for you, there are always hand presses. They only need enough room on the shelf to store their box. When I first started reloading I had no dedicated space at all. I reloaded while sitting at the kitchen table, using a hand press for several years.

2. Get A Single Stage Press

Advertisement — Continue Reading Below

Everyone should have a good single stage press. Beginners should learn to craft high quality handloads on a single stage press without the complicating factors imposed by a progressive press. Even experienced, high volume reloaders should have a good single stage press around the shop. I use a progressive press for all my high production pistol calibers, in fact I load 13 different calibers on progressive presses, but I still use a single stage press quite a bit. I use the single stage press to load calibers like .455 Webley, where the volume of ammo I produce doesn’t justify setting up a dedicated tool head on the progressive press.

I also use a single stage press whenever I’m working up a new load for an existing caliber, or when I’m building precision long range ammo where powder charges need to be exact. In those cases I use a single stage press and a powder trickler. You will always find uses for a single stage press.

3. Everyone Makes High Quality Reloading Dies

Advertisement — Continue Reading Below

In 30 years of reloading, I have yet to find a bad die from a major manufacturer, and I have yet to wear out a reloading die, regardless of who made it. I use dies from RCBS, Lyman, Lee and Redding. They are all good, and any manufacturer’s die works on any other manufacturer’s press. If you want to stay loyal to the green team, or the red team or whatever, that’s fine, but don’t pass up a bargain if differently colored box comes your way.

4. Powder Measures Are As Important As Presses

Advertisement — Continue Reading Below

Always invest in a quality powder measure. With some powders a very small amount can mean the difference between a safe load and a trip to the hospital. So spend the money on a good powder measure, and use it properly. When I am getting ready to reload. I always throw at least a half dozen test loads onto my scale to be sure the measure is calibrated correctly. That is a pain to do on an auto-indexing, progressive press, but it is important to do so. On progressive presses, you really should have a dedicated powder measure on each tool head. Set them, and check them before each reloading session.

- RELATED STORY: Velocity & Accuracy Testing For Handloads

You should also check your powder measure during each reloading session. On single stage presses I check my measure by weighing a powder charge after every 25 rounds. When I’m using a progressive press I weigh every 50th powder charge.

5. Keep A Balance Beam Scale Around

Advertisement — Continue Reading Below

Digital scales are excellent, and they are really very reliable these days. That said, I still think you ought to keep a balance beam scale around the bench. Old-school is always right on! My go-to digital scale will operate powered by either batteries or by an A/C adaptor, But, I usually end up running on batteries. Whenever I change batteries and calibrate the digital scale, I check it against the balance beam scale.

More to the point though, if you have a long-term power outage, you will still be able to reload. A few years ago we had an ice storm that knocked out our power for almost a week. Luckily we are prepared for situations like this with food, water, and the other necessities of live. But, when the power went out, I realized how much of our entertainment depends on electronics. But, with a battery powered lantern lighting the way, I was able to pass the hours pleasantly by reloading. Balance beam scales use no power, and they can keep you reloading when the grid goes down.

6. Use Cartridge Gauges

Advertisement — Continue Reading Below

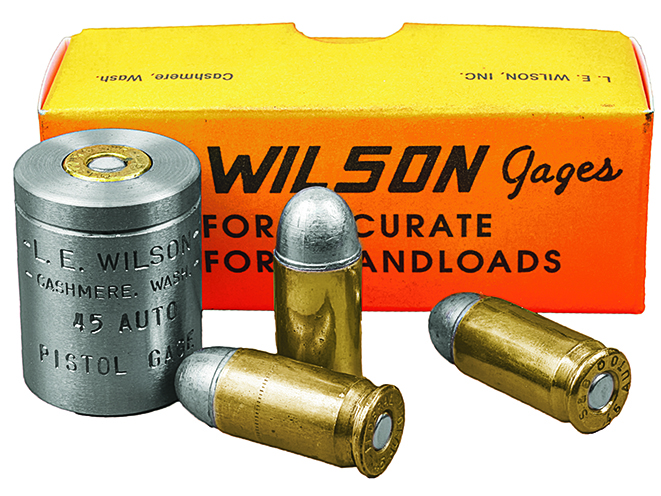

With revolver cartridges, if you can get the round into the chamber, the gun will operate just fine. Even if the cartridge isn’t perfect, and you had to strain to get the round in the chamber, once it’s in, everything will work fine. That’s not the case with semi-automatic pistols. Ammo that is not perfectly within the dimensional specs for that round generally won’t chamber, jamming the gun. That’s why I always use L.E. Wilson Max Cartridge Gauges when I’m loading rounds for semi-auto pistols. These gauges will rapidly show you if your ammo will chamber cleanly in your gun. Properly sized ammunition drops completely, and easily into the gauge. If the round fits into the gauge, it will chamber cleanly. When I’m reloading pistol ammo, I drop every 10th round into the appropriate L.E. Wilson Max Cartridge Gauge for its caliber. I have a shelf of these little gauges for the various handgun cartridges I reload. I consider them essential equipment.

7. Buy A Reloading Manual

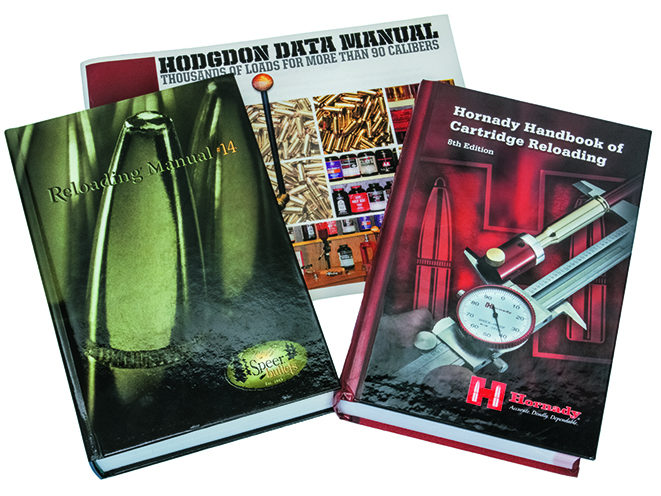

Don’t depend on pet loads that you get from friends. And for heaven’s sake, don’t rely on loads you find posted on internet forums. Handloaders who do that end up with the nickname “Stumpy”. Don’t be that guy. There are some great reloading manuals out there. Buy at least one of them, and use the recommended loads you find in there. These loads have been tested by experts, and they will be safe to shoot in well-made guns.

Advertisement — Continue Reading Below

- RELATED STORY: 9 Next-Gen Bullets To Maximize Performance

Inexperienced reloaders should not go off book for their loads. Even experienced reloaders will rely on manuals when they are developing loads. I load a few cartridges that have no currently published loading data, so I have to develop my own loads from scratch. Even for those cartridges, I still go to my reloading manuals to find several other cartridges with similar capacity and pressure values. I then use data from those cartridges, in conjunction with burning rate data for the powders I’m considering, to develop safe minimum and maximum loads for testing. So get a good manual, and use it.

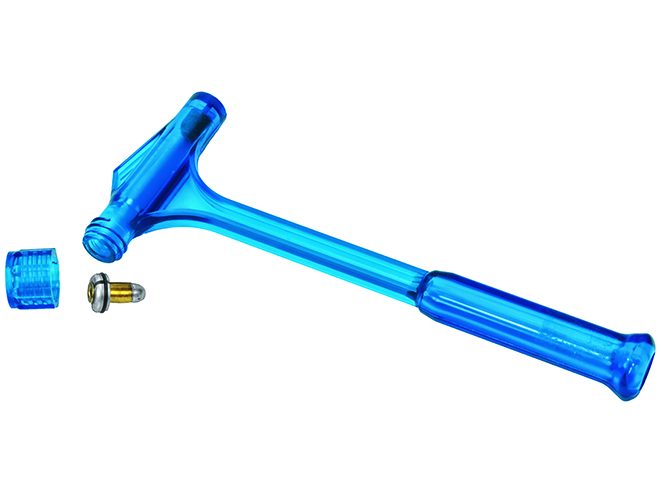

8. Keep A Kinetic Bullet Puller Handy

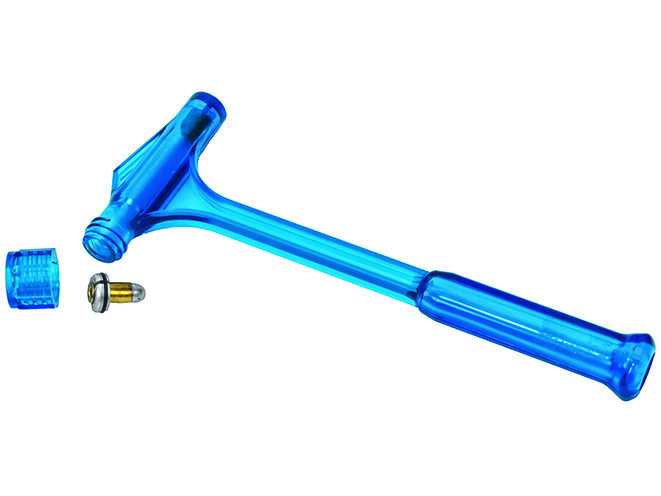

Mistakes happen. Powder measures can get out of calibration; sometimes the wrong primer gets used, and, sometimes you’re so sure that a new load will be a winner that you load up a big batch before trying it out at the range. Then you find out it performs like a dog. For whatever issue you run into, a kinetic bullet puller will let you to quickly break down your mistakes and reuse the brass.

Advertisement — Continue Reading Below

9. Curing Crimped Primers In Once-Fired Brass

A big reason for reloading is to save money on ammunition, and, aside from free brass that you scrounge at the range, once-fired brass is generally the most economical brass that you can buy. But used brass can come with some issues that you need to be prepared for.

The first issue is crimped primers. Most ammunition produced for the military, and some ammo produced specifically for law enforcement, have crimped primers, which means that the brass around the primer pocket has been swaged or staked tighter after the primer was installed. A typical batch of used brass will be have a high percentage of cases with crimped primer pockets.

Crimped primers can be harder to punch out. Some people report broken de-capping pins from crimped primers. Personally, I have never broken a pin on one. The bigger problem is that new primers won’t go into a crimped primer pocket. That can really mess you up, especially on a progressive press.

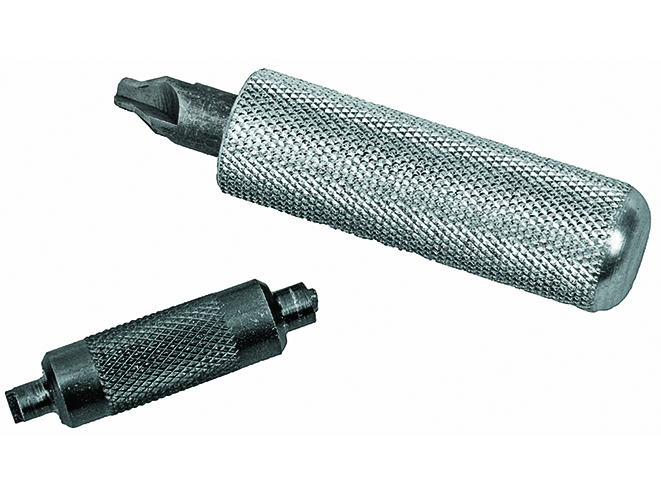

The good news is that there are a number of tools that cure that issue. RCBS makes a primer swaging die. It works great, but it is pretty pricey. The price may be worth it if you are going to be doing a lot of crimped brass. Personally, I use a couple of Hornady primer pocket reamers, one for small primers and one for large primers. They only cost about a sawbuck apiece, but they require a little more sweat equity than a swaging die. In a pinch a case mouth chamfering tool works too.

- RELATED STORY: The 10-Shot Rule For Determining Handload Accuracy

When it comes to crimped primer pockets, the big question everyone has is how to identify them. After all, if you just bought 10,000 pieces of once-fired brass, you don’t want to have to de-crimp every piece of brass in the bag. Crimped primers are often visible to the naked eye, but I prefer to look at the head stamp. If the head stamp is a standard commercial stamping, like, “Federal 9mm Luger”, for example, it won’t have a crimped primer. But, if it is an odd head stamp, like, “WWC 10”, it is a military round, and it will have a crimped primer pocket. Sort those out, and cut out the crimped pockets.

10. Trimming Belly Bulge

Another issue with once fired brass is belly bulge. I’m not talking about the kind that Marie Osmond can help you with. When brass is fired in an unsupported chamber it can develop a bulge. Sometimes this is noticeable, but often it isn’t. Some calibers and guns are more susceptible to belly bulge than others. One of the worst offenders, in my experience are .40 S&W cases that were fired through a Glock, though .357 Sig, and 10mm can also be a problem, especially if they were hotly loaded.

The problem with belly bulge is that your full-length sizing die won’t fix it. In most cases you won’t even know that you have a problem until the reloaded, bulged case fails to chamber. That’s another great reason to use Wilson’s Max Cartridge Gauges. They will catch that before those rounds ever get to your gun. The cure for bulged bellies is pretty simple. Several companies make dies specifically to iron out bulged bellies. Lee Precision sells a bulge buster kit, and Redding makes their G-RX base sizing die kit. Both of these kits work the same way. You push the cartridge case completely through a carbide sizing die. These kits absolutely work, and I run all my used .40 S&W and 10mm brass through one before reloading.

Use these tips help to make your reloading more fun and efficient.

This article was originally published in ‘The Complete Book of Reloading’ 2017. For information on how to subscribe, please email subscriptions@