The sounds of CNC machines never stop. You can walk onto a workroom floor any hour of the day or night and the activity never ceases. That is one of many reasons why SCCY is now among the most successful pocket pistols manufacturers in the country. Pronounced “Sky” after the original Skyy Industries founded in 2003 by CEO Joe Roebuck, the SCCY CPX-3 is the company’s first .380 ACP pistol and the first SCCY model to utilize the innovative Roebuck Quad-Lock system for improved barrel stability and accuracy.

In creating the Quad-Lock system, Roebuck, who is also the company’s head of design and engineering, addressed a common problem with .380 autopistols as well as other semi-automatics using a locked-breech design. As Roebuck explained it, “Gunmakers have pretty much come up with their own solutions to locking up the chamber side of the barrel, however, from what I have seen, their lock-up in the rear part of the barrel doesn’t always repeat. You have a lack of consistency. [Looking at] barrel and lockup systems and seeing how the barrel wiggled in the front has always bothered me. I wanted to come up with a solution that could be manufactured effectively and cost efficiently. The Quad-Lock design does both. This design offers a solution by which the barrel is going to consistently repeat when it is locked and unlocked by going into the same location every time, and it is cost effective to manufacture.”

Lock It Up

Advertisement — Continue Reading Below

The new barrel design makes its debut in the CPX-3. Distinctive in its design, the first half of the barrel lug is angled and then turns flat. At the rear there is a step or tang. Roebuck explained that the tang has a curved edge that marries up to the slide when the gun is fully locked.

According to Roebuck, “This occurs because the barrel’s cam system is radiused to rotate around the disassembly pin and push the back of the barrel upward. This forces the tang to engage the front port section of the slide.” That comprises two of the four lock-up points in Roebuck’s Quad-Lock design. The second part begins with the front of the barrel (muzzle) being pushed downward. This is where the real difference occurs in the Quad-Lock. In the various semi-autos that Roebuck studied, the barrels were loose around the muzzle opening of the slide.

RELATED STORY: First Look – SCCY’s Ultra-Compact CPX-3 Pistol

Advertisement — Continue Reading Below

Roebuck said, “You need that clearance when the barrel unlocks, but you don’t want any clearance when it is locked up, you want that barrel solid when it is locked up.” Since the barrel is already locked at the rear of the lug, the CPX-3’s recoil system forces the front of the barrel downward. It is this feature that uniquely defines the Quad-Lock. Looking at the CPX-3’s slide from the front, it has a crescent-shaped gap just above the barrel while the bottom of the barrel is sitting almost flush against the muzzle opening. It looks off center but it’s not, because the muzzle opening in the CPX-3 slide is not round.

“There are two angles that are 90-degree inverted if you come off the centerline at 45 degrees each,” explained Roebuck, “and what happens is that when a round barrel goes into an opening that is a ‘V’ it will always center itself and always stay rigid, so long as there is pressure pushing down.” A CPX-3 barrel won’t move from side to side if you push it. It is locked in place. This “V” comprises the latter lock-up points.

As the gun is shot, the barrel is forced further into the “V,” so it is locked up even tighter at the moment of discharge. The result of the Quad-Lock is a significantly more stabilized barrel and improved accuracy. “In actuality,” explained Roebuck, “when you are aiming a semi-automatic pistol, you are actually aiming the slide, so if you have the barrel loose inside the slide that takes away from accuracy. In a magical world, the barrel and slide (while locked up) would be one piece; as soon as the gun is fired and the projectile leaves the barrel, they become two pieces. That is exactly what the Quad-Lock system has created with the barrel repeating the lock-up in the exact same place and remaining rigid with the slide to make it more accurate.”

Advertisement — Continue Reading Below

SCCY-High Standards

Roebuck said there is no other lock-up system in use like the SCCY Quad-Lock. This technology will likely filter down into the entire SCCY lineup and be used in future models. The precision design is made possible through a combination of CNC machining coupled with CNC inspection equipment.

“At SCCY, we have the ability to inspect to very high tolerances and qualify those tolerances with CNC coordinate measuring machines that go back and check to see if something goes out of spec,” explained Roebuck. In CNC manufacturing, you have cutting tool wear to consider, “and as a cutting tool wears it changes the dimensional. We have a very, very high percentage of inspection [to minimize that]. Most manufacturers inspect five to 10 percent. We are way beyond 50 percent depending upon the part. SCCY has five CMM inspection machines, of which there are two types, four of them use five-axis probes with a sapphire tip to physically touch each part and compare it to the program inspection points. The program tells you if the part either passes or fails and by how much, so there is great consistency to individual parts. The fifth, a coordinate measuring machine (CMM), performs an optical inspection using a camera to view the part and send that information back to the computer to compare with program inspection points. The more complex parts, like slides, receivers and barrels, are beyond 50 percent with a dedicated machine just to inspect those three parts.”

Advertisement — Continue Reading Below

Roebuck admitted to being a bit obsessive. “I’m a perfectionist, I’m a quality freak. I won’t take shortcuts, even if it cost me a little extra. I want it to be perfect.” SCCY’s Joe Roebuck comes from a different place than many gunmakers because he began as a tool and die maker and mechanical design engineer. “I wear many hats at SCCY. I have been told that I am an unusual CEO, which I am, because I not only do the top end business and finance, I am also down in the trenches designing both the tooling and the guns.”

Each pistol is hand-fitted at final assembly, the last step to assure that every part in every gun meets Roebuck’s exacting standards of fit and operation before it leaves the production floor to be test fired. Considering that every component of the SCCY, with the exception of springs, is manufactured in-house, including the 10-round magazines, (the injection-molded Zytel frames are produced in a separate SCCY facility), the obvious question that arises is, “Why isn’t this gun selling for $500 instead of less than $320?” Roebuck said that answer is simply because of his entire business model.

RELATED STORY: Gun Review – SCCY CPX-2 – Compact, Concealable, Affordable

Advertisement — Continue Reading Below

“When I went into the industry, I wanted to do something different and I kind of coined the phrase ‘technology with the presence of talent and a lack of greed.’ I am happy with the margins we have. And we are definitely a volume house, we would not be successful if we were not. The CNC machines run 24/7 in three 8-hour shifts seven days a week.”

Roebuck has shift changes with 30-minute overlaps so personnel can hand off operations and communicate whatever is going on and what needs to be done for the subsequent shift. Final assembly runs five days a week. Monthly production at SCCY is (as of this writing) 15,000 guns per month, but that will have increased by the time you read this to 22,000 CPX models monthly. That results in an estimated annual production of approximately 264,000 units.

Fit & Finish

Advertisement — Continue Reading Below

The CPX-3’s slide is an exemplary design that eschews the flat, slab-sided look of most semi-autos priced under $500. It has replaceable, dovetailed white-dot sights, a curved and beveled contour, five deep grooves at the rear of the slide for a solid grasp, a hand-filling grip with solid heft for a polymer-framed gun and an extended triggerguard that allows for a gloved hand in cold weather. A large and easily activated slide release and a positive button-type magazine release completes the exterior features.

The pistols use stainless steel, broach-rifled barrels, and the double-action trigger and internal hammer mechanism are ruggedly built for dependable operation. The 10+1 capacity CPX-3 in .380 ACP (like the 9mm CPX-2 and CPX-1) is incredibly simple to operate, with no external safeties other than the DAO trigger and an internal drop safety. It is also one the easiest guns in the world to field-strip in only three steps: Lock the slide back and drop the magazine (thus clearing the action), extract the disassembly pin and pull the slide off the frame. Reassembly is reverse order. It only takes a few seconds to take a CPX apart.

RELATED STORY: Reach for the SCCY with the Compact CPX-1 and CPX-2

Advertisement — Continue Reading Below

“There is nothing in the way the SCCY is produced that is lacking quality,” said Roebuck. “We do not take any shortcuts, but there is high-end technology involved here and a lot of trade secrets in how the parts are machined. As an example, most of our competitors require five to six steps to make a slide. We do it in two. In manufacturing, every time you handle a part it costs time and you’re taking a chance of spoiling the part. The less you handle it, the more cost effective it will be and you get a higher yield.”

It has required an enormous amount of money from idea to production to establish SCCY and manufacture the CPX-1, CPX-2 and CPX-3 models. “I still do 100 percent of the design and part of the tooling design along with an engineering crew,” said Roebuck. “We do all of this in-house and we manufacture the majority of our own tooling as well. This saves a lot of money.”

Taking Aim

Advertisement — Continue Reading Below

The .380 CPX-3 is a little larger than many subcompacts, but it is easier to handle and its recoil is lighter than most (size equals greater distribution of energy). This gun is small enough for pocket carry and certainly in any number of lightweight belt and inside-the-waistband rigs. The grip is short because the SCCY uses a staggered 10-round magazine, so with the flat baseplate, the little finger has to tuck under the magazine. This is alleviated with the finger extension, which provides a full-hand grip for most people. The CPX-3 is a little longer and a little wider than .380s like the Ruger LCP, even a bit more than a Colt Mustang, but in exchange you have a 10+1 capacity versus 6+1. This is the highest capacity of any of the top .380 ACP semi-autos on the market, and it may well be the most accurate.

The trigger pull on the test gun averaged 6.5 pounds. Travel is a full inch with no stacking and a crisp break. It does take nearly a full release of the trigger (0.75 inches) to reset, but the DAO has second-strike capability, a definite plus, along with no magazine disconnect, so it can fire a chambered round with the magazine removed.

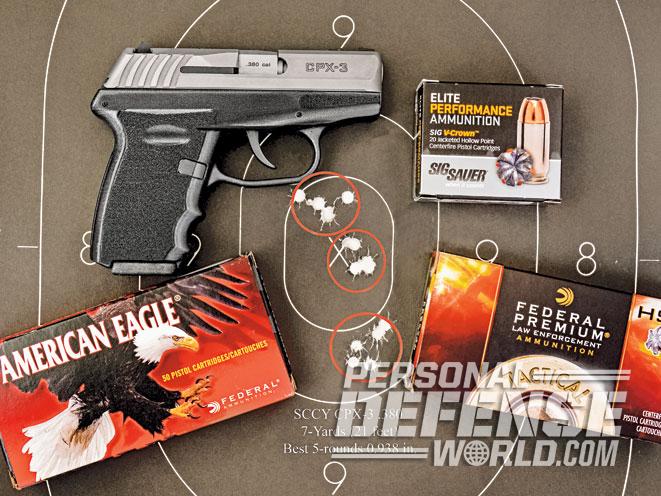

I used three loads to test the SCCY: Federal’s 95-grain American Eagle FMJs, Sig Sauer’s 90-grain V-Crown JHPs and Federal 99-grain HST ammo. I placed a target at 7 yards and fired off-hand. Ultimate accuracy comes down to the individual shooter’s abilities, but an accurate gun to start with is an asset. The SCCY delivered a best five-round group with the Sig Sauer ammo of 0.93 inches. The Federal HST ammo grouped into an inch, and five American Eagle rounds clustered into 1.125 inches.

RELATED STORY: SCCY CPX-1 9mm Handgun Series | VIDEO

There were no failures to feed or malfunctions with all three brands of ammo. As for recoil, even the heavy-hitting 99-grain Federal was more than manageable, and the pistol’s white-dot sights were quick to reacquire from shot to shot. The most impressive of all was the consistency and ease of trigger pull, which, combined with the SCCY’s Quad-Lock design, keeps this little .380 in the center of center mass.

Parting Points

There are a lot of people at SCCY, from the workroom floor to the design lab to the marketing group. This company is truly a team that is dedicated to winning by doing what no American armsmaker has done before—build a semi-auto to exceed in performance, quality and features where no such expectations at the price point exist. Is this a $500 gun for a little more than $300? By today’s standards it is that and a bit more.

For more information, visit http://www.sccy.com or call 866-729-7599.