Check out the video of our visit to Ruger’s newest facility below!

PersonalDefenseWorld.com was recently given a chance to get a behind-the-scenes look at the new Ruger manufacturing plant located in Mayodan, North Carolina. A select group of writers was invited to tour the new plant where the company is producing the Ruger American Rimfire rifle, as well as a secret project that is still under wraps.

At the beginning of the tour, Ruger’s CEO, Mike Fifer, gave the assembled group some background on the new plant. He explained that Ruger’s unprecedented growth over the past few years had maxed out the production capacity of its New Hampshire and Arizona facilities. Production had increased fourfold, and the number of employees had gone from 1,300 to 2,400 to meet the demand. As a result, the company realized it needed to expand.

Advertisement — Continue Reading Below

After an exhaustive search around the country, the area of Mayodan, North Carolina, was determined to be a finalist in the selection process. Ruger soon discovered that the area was filled with a highly capable and motivated work force that was very friendly to the firearms community. That, combined with an empty 220,000-square-foot plant that would fit the company’s needs quite well, ensured that an expansion to Mayodan was the right move for the company.

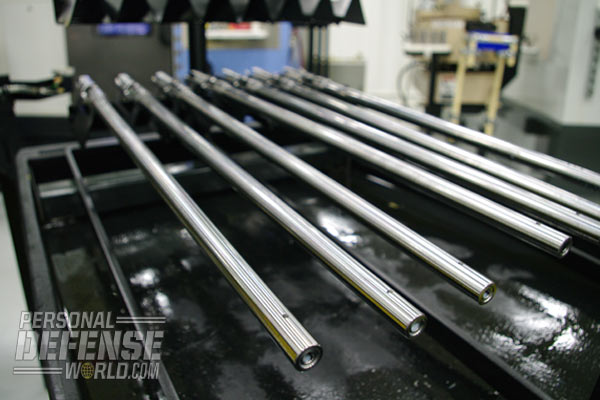

Mickey Wilson, director of operations at the Mayodan plant, then brought the group up to speed on the role that the plant is designed to play in the bigger picture. Currently, the plant produces the American Rimfire rifle line, including a state-of-the-art barrel hammer-forging machine. In addition, he dropped a hint that there is another secret project going on at the facility, but said we would have to wait to find out more on it.

Wilson went on to detail the process behind getting the plant up to speed, letting us know that they managed to get the first production rimfire rifle off the line an astounding 60 days after acquiring the building. This included cleaning and refurbishing the facility, setting up the equipment, etc. All in all, it’s an amazing accomplishment. Wilson went on to describe the manufacturing processes employed at the plant, stating that it follows a “lean production” philosophy that is designed to maximize efficiency and minimize waste.

Advertisement — Continue Reading Below

Part of this process is what he described as a “super cell” system of production in which dedicated production lines group together processes and employees so that everyone needed is there to build a complete product. Each “cell” is a mini factory, or a “plant within a plant.” This process results in greater efficiency and accountability, which they claim makes for a better final product.

We would like to thank Ruger for giving us the opportunity to take a look behind the scenes at the new plant and key us in on what is happening there. Keep an eye out here for information on the “secret project” as we find out more!

For more information, visit http://www.ruger.com.

Advertisement — Continue Reading Below