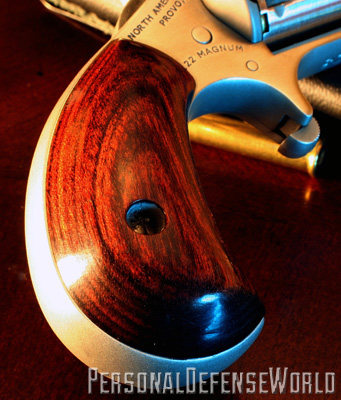

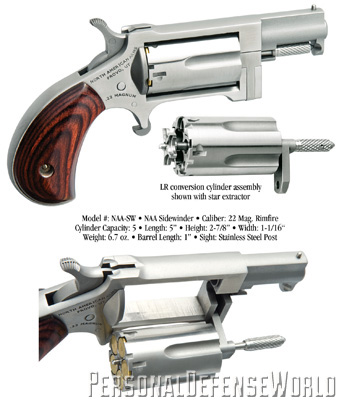

A while back I had a conversation with Sandy Chisholm, the owner of North American Arms (NAA), and we discussed the company’s guns. Afterward I asked the question that is on the minds of most writers when they’re talking to a gun manufacturer: Have you anything new brewing? Sandy proceeded to speak very cryptically about something in the works, which was going to be a first, not only for NAA but also for mini-revolvers all around. I tried to press him for more details, but it was clear he wanted to keep the project under wraps until the company could unveil it. Finally, as I prodded him to at least give me a hint of what was to come, he simply said, “Think in terms of a traditional, full-sized revolver.” That was all I got. But it all made sense when the Sidewinder finally hit the market in November 2012. Luckily, I had bugged General Manager Ken Friel for quite some time to make sure I got one of the first samples to test and evaluate.

Mini Details

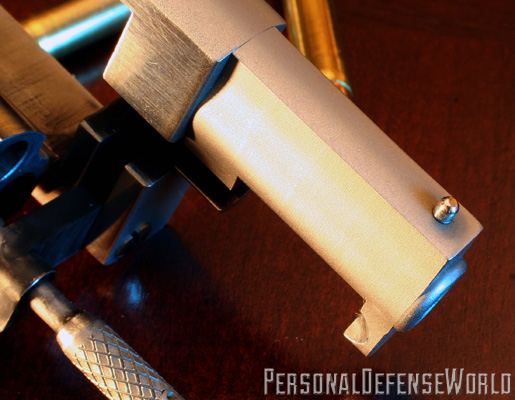

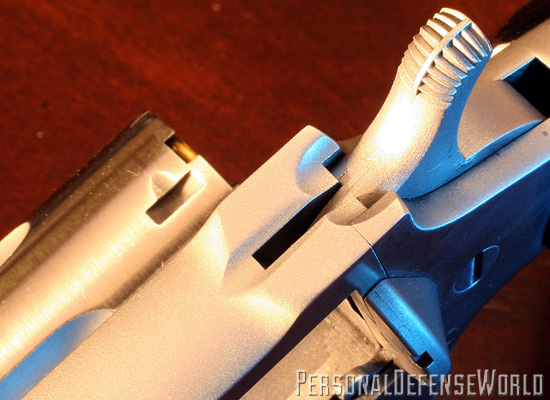

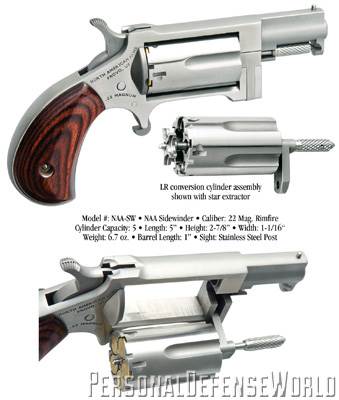

The Sidewinder is a mini-revolver sporting a cylinder that swings out on a crane like traditional, larger revolvers do, the obvious advance in design being ease of reloading. Opening the cylinder involves drawing the hammer to half-cock, then holding the Sidewinder in the left hand and pointed to the right (in a safe direction, of course), grasping the knurled portion of the cylinder pin forward of the cylinder, and pushing it toward the muzzle. The cylinder may then be pushed out with the left index finger. Once the cylinder is either loaded or unloaded, with the hammer still at half-cock the cylinder is closed by pressing on the crane until the cylinder is fully closed and the pin is fully seated in the retaining slot under the barrel. Once loaded, align the large and small slots at the cylinder’s rear with the corresponding slots on the recoil shields. Then the hammer may be carefully lowered into its safety slot with the thumb while squeezing the trigger. These safety slots allow the revolver to be carried fully loaded with a round in all five of the chambers.

Machined from 17-4 PH stainless steel bar stock, the barrel itself is relatively flat on top with a very slight roundness and possesses a small underlug forming the retaining slot for the cylinder pin. The rate of twist for the 1-inch barrel is 1 in 12 inches with eight lands and grooves. NAA is exploring the possibility of using MIM (metal injection molding) to make the barrel, but personally, I believe the bar stock might make for a better barrel…

Advertisement — Continue Reading Below

GET THIS ISSUE NOW! at personaldefenseworld.com/subscribe/concealed-carry-handguns/.