The StG44 was the first service rifle designed to match the realities of the modern battlefield. Every rifle that came before it, whether a slow bolt-action or a semi-automatic with limited magazine capacity, had surrendered its close-quarters responsibilities to other small arms like pistols, shotguns and submachine guns.

- RELATED STORY: 8 Rimfire Replicas of History’s Greatest Battle Weapons

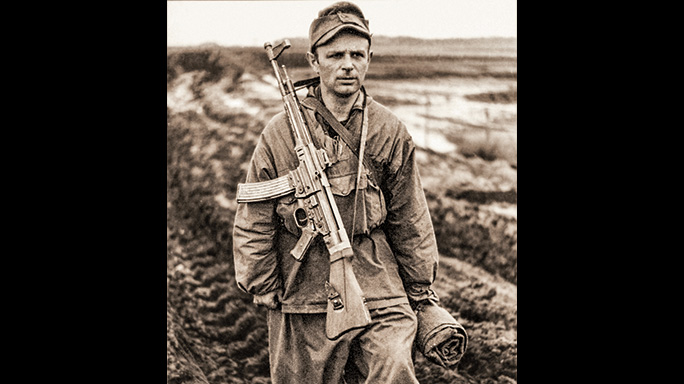

Using a medium-power, mid-range cartridge, the StG44 was as controllable as most submachine guns were during full-auto fire. Accurate out to 300 yards, it was useful as a carbine as well. In fact, the StG44’s performance was so revolutionary that its name, Sturmgewehr, which is German for “assault rifle,” was bestowed on a new class of select-fire service rifles inspired by the StG44.

The story of the StG44 starts with the aftermath of World War I. The German Army’s surveys of infantry combat found that most riflemen rarely fired their weapons at ranges beyond 400 yards. However, most military cartridges, including the 8mm Mauser, were designed to maximize the service rifle’s range. Prior to WWI, generals in every European army still envisioned 19th century battlefields where massed men fired volleys at other groups of massed men. But these generals soon discovered that 20th century firepower made that impossible. In order to survive a battlefield dominated by machine guns and quick-firing artillery, infantrymen had to spread out and take cover. Individuals or small groups found it necessary to cover ground in rushes and aim at individual targets, since the enemy rarely appeared in large groups.

Advertisement — Continue Reading Below

Taking these lessons to heart, the German military investigated the possibility of eliminating the unused long-range performance of its service-rifle cartridge, in hopes that the reduced recoil and energy would be compatible with controllable fully automatic operation. In their eyes, they were trading away power that was never used anyway, except by snipers and the most gifted marksmen in the unit. The full-auto firepower would then maximize the effectiveness of every soldier.

In 1936, Polte Ammunition Works developed the 8mm Kurz (kurz means “short” in German) cartridge at the request of the German Army Ordnance Board, known as the Heereswaffenamt, or HWA. It used the same case base as the 8mm Mauser, which was bottlenecked but had an overall length that was reduced from 57mm to 33mm. The resulting 7.92x33mm “8mm Kurz” also used a shorter, 124-grain, spitzer bullet that was significantly lighter than the 198-grain projectile used in the full-power 8mm Mauser.

Carbine Face-Off

Advertisement — Continue Reading Below

With the critical work of cartridge development done, the HWA asked Walther and C.G. Haenel to develop a select-fire carbine that could make the most of the new cartridge. Haenel’s carbine was designated the MKb42(H), and the Walther gun was dubbed the MKb42(W). Both guns were similar up to a point: They were select-fire weapons that fired from the open-bolt position on full-automatic and from the closed-bolt position on semi-automatic, they were built from a significant number of stamped-steel components for rapid production and both used the same detachable, 30-round magazines. Where the weapons differed was in their operating systems—the Haenel gun’s mechanism was very simple, while the Walther’s was overly complex. Thousands of Haenel and Walther MKb42 carbines were built for field trials in 1942.

Both designs proved to be very popular with the troops. The guns were accurate and controllable on full-auto, so they doubled the firepower of any unit lucky enough to receive them. Not surprisingly, troops and commanders involved in the field trails immediately wanted more MKb 42 carbines and 8mm Kurz ammo. HWA considered the Haenel design more promising, so it dropped the Walther gun and asked Haenel to further refine and simplify its MKb42(H). Haenel’s improved gun would fire from a closed bolt on both full- and semi-automatic. In addition, the weapon’s gas expansion chamber in front of the piston, deemed unnecessary, was eliminated.

By any standards, the MKb42 was a winner. It was battle proven as well as cheap and easy to produce. There was, however, one problem, and it was a big one. Hitler was adamantly opposed to the MKb42 project, as his own combat experience during WWI left him convinced that the bolt-action K98 was all a soldier needed; he wanted the MKb42 project scrubbed immediately. However, the HWA knew it had something that would potentially revolutionize infantry tactics and give German soldiers a decisive edge in close combat.

Advertisement — Continue Reading Below

Undercover R&D

So the HWA did the only thing it felt it could do under the circumstances—it hid further development and production of the MKb42 from Hitler and ramped up its production as much as possible. The HWA renamed the carbine the MP43 (Maschinenpistole 1943), hoping to disguise it as a new submachine gun. The name change did the trick. Submachine guns didn’t interest Hitler, but he was not opposed to them. Production and after-action reports from the front were camouflaged under the new name or buried beneath mountains of bureaucratic documents.

The revamped and renamed MP43 was a significant improvement over the MKb42. It was more reliable and easier to manufacture and therefore more numerous. Tens of thousands were made and issued exclusively to troops on the Eastern Front. This time, its distribution was much broader, including to mountain troops, light infantry and mechanized infantry. Before long, the MP43’s battlefield impact and popularity among the troops became impossible to hide.

Advertisement — Continue Reading Below

Hitler reserved the right to personally present the highest grades of the Knight’s Cross. He didn’t trust his generals, so this was a way to maintain the troops’ loyalty and get an unvarnished view of the front. After a series of desperate battles during the winter of 1943-1944 that involved his most elite and trusted Waffen-SS troops, he asked, “What do you boys need?” Much to his surprise, they enthusiastically replied that they needed more select-fire MP43 carbines—the cat was now out of the bag. Vexed, Hitler was faced with two options: kill the MP43 and risk alienating his troops, or somehow redeem it by making it his own idea. He chose the latter. Hitler renamed the MP43 as the Sturmgewehr 44, and the rest is history. For the second time in a year, the MKb42 program was ultimately saved by changing its name.

When the Haenel gun was chosen over the Walther in 1943, Walther dropped out of the MKb42 program so it could focus on producing G43s and P.38s, but the MKb42’s legitimacy opened up vast new resources for production. In all, four companies were put to work making StG44s: Haenel, Erma, Steyr and J.P. Sauer.

The MP43, MP44 and StG44 are all the same gun, and their parts are interchangeable. Only the MP43/1 is an outlier. It has a built-in scope rail, similar to the one on the G43, and its barrel is slightly thicker, so an MP43/1 barrel cannot be mounted on an MP43, MP44 or StG44 and vice versa. The different names didn’t signify any physical changes in the gun, but you can find numerous small differences in finish and furniture.

Advertisement — Continue Reading Below

For example, the reinforcing ribs on the upper receiver evolved over time. And at some point during MP43 production, the Germans switched to a stock with smaller dimensions that was compatible with K98 vehicle and barracks storage racks. But none of these changes or simplifications is related to changes in the gun’s name. Most of the guns were stamped “MP44”. Those stamped “MP43” are the second most common, while those stamped “StG44” are relatively rare.

Efficient Design

Hugo Schmeisser was the lead designer at Haenel, and the Haenel MKb42 and its progeny, the StG44, were his creations. Schmeisser worked for the manufacturer Bergmann during and after WWI. During that time, he designed the first successful purpose-built submachine gun, the MP18. Twenty years later, a rival group of designers from Erma incorporated the MP18’s unique telescoping recoil-spring housing into its MP40 prototype, much to Schmeisser’s chagrin. By any historical standards, he was a gifted small-arms designer.

Advertisement — Continue Reading Below

Schmeisser chose simple and proven design elements for the StG44, including long-stroke gas piston operation and a Blish-style locking system for the bolt, and combined them with modern and economical manufacturing techniques ideally suited for rapid production, such as precision sheet-steel stampings like those used in the MP40 and MG42 designs.

The tail of the StG44 bolt locked into a well at the rear of the forged-steel action block, while the 16.5-inch barrel was pinned to the front of the action block. The stamped-steel upper receiver wrapped around the action. A combination of welds and matching contours hold the action block in place. The rear half of the upper receiver resembles two tubes stacked one on top of other: The bottom tube serves as a housing and a raceway for the bolt, while the top tube serves the same functions for the gas piston assembly.

Hooked ears and angled surfaces on the bottom of the piston lift the tail of the bolt out of its locking recesses at the rear of the action block. Nested behind the bolt/piston assembly is a very large coiled-steel recoil spring. During the firing cycle, it compresses into a recess cut into the wooden stock. Baffles on the piston and a pair of circular vents in the stamped-steel gas tube minimize stress on the working parts. A plug threaded into the front of the gas block allows access to the gas tube for cleaning and maintenance. A very trim stamped-steel handguard shrouds the barrel between the face of the upper receiver and the gas block. Like the upper receiver, the lower receiver is a stamped-steel assembly. It serves as a pistol grip and housing for the trigger components. The front of the lower receiver is hinged to the upper receiver at the rear of the magazine well.

Advertisement — Continue Reading Below

A single takedown pin connects the wooden stock, the upper receiver and the lower receiver. Pushing out the takedown pin and pulling the stock to the rear allows the rear of the lower receiver to swing down and away from the upper receiver. As the rear of the lower receiver falls downward, the front hangs on a hinge pin at the rear of the magazine well. The hinge pin is fixed and can be driven out by an armorer gunsmith, but it was not meant to be removed during field-stripping or everyday maintenance.

A charging handle fixed to the piston travels in a slot on the left-hand side of the StG44, so you work it with your support hand. The safety lever is also on the left-hand side of the gun, just above the trigger, and has a rather short 60-degree throw. Pushing down with your thumb readies the gun to fire and reveals an “F” for fire, which is stamped into the side of the assembly. Pushing up on the lever engages the safety mechanism and reveals an “S” for safe. Just above and forward of the safety lever is a select-fire button that works much like a cross-bolt safety. Pushing the button left reveals an “E” for einzelfeuer or semi-automatic. Pushing the button to the right reveals a “D” for dauerfeuer or full-automatic. A very large, circular magazine-release button is on the left-hand side of the magazine well. This arrangement of controls creates an interesting setup. You work the trigger, safety and selector with the fingers and thumb of your firing hand, but you manipulate the charging handle and magazine release with your support hand.

The StG44 has a long, two-stage trigger pull much like the M1 Garand’s. In addition to the thumb safety, it also has a bolt safety. When the bolt is out of battery, the bolt safety blocks the movement of the trigger so it can’t release the hammer. Schmeisser felt that this feature was necessary in a carbine capable of fully automatic fire.

Advertisement — Continue Reading Below

The rear sight is a blade with a V-notch mounted on a raised base that’s located about halfway down the top of the receiver. With a sliding ramp indexed to 800 meters, it is adjustable for range. The front post is dovetailed to the top of a tall base pinned just behind the muzzle. A sheet-steel hood protects the post.

The MP44/StG44 is a big carbine. It is both longer and taller than an AK-47, and the extra length of its receiver prevents the bolt from bottoming out inside of it. This ensures that the shooter never perceives the bolt’s movement as part of the recoil impulse. Combined with the inline stock, the smooth travel of the bolt is a big part of what makes the StG44 very manageable even on full-auto. Remarkably, I have found it to be as controllable as an MP40 or even an M4, given that the 8mm Kurz and the AK-47’s 7.62x39mm round have nearly identical ballistic performance. Both rounds fire 124-grain spitzer projectiles and have bullet drops within an inch of each other at any given range when the loads are zeroed to the same distance.

The StG44 hits as hard as an AK, but it is as controllable as an M4. The StG44 also shares the AK-47’s range limitations. The StG44’s maximum range is really 300 yards because, at that point, the bullet starts sinking like a stone. The StG44 not only is bulkier than an AK-47, but it also has a longer mag, which is gently curved. The comb is tall, so you get a good cheekweld, and the curved shape of the butt sinks into the shoulder pocket. The pistol grip is nicely raked and fills the hand. In sum, the contour and size of the stock and pistol grip greatly enhance its controllability on full-auto. One sticking point is the handguard. It is thin and wraps tightly around the barrel, so it gets hot fast. During sustained full- or semi-auto fire, a shooting glove for the support hand is almost a necessity.

Modern Warfare

Early MKb42 and MP43 test runs were limited to light and mountain (Jaeger and Gebirgsjaeger) units. The HWA hoped that a “pure” infantry environment would create the best laboratory for these experimental small arms. Also, given that these light infantry units were short of artillery and mortars, they were most in need of the extra firepower. Later on, after the MP44/StG44 was legitimized and became more numerous, it was issued to every kind of infantry unit, including mechanized, motorized, regular, light and elite mountain units. Paratroopers got some as well, even though the Luftwaffe, which controlled the paratroopers, was not supportive of the MKb42 program.

Wanting a full-power automatic rifle in 8mm Mauser, the Luftwaffe started a project of its own, the FG42. It was a great gun, but it proved to be almost impossible to mass-produce, at least during wartime. Officially, the Luftwaffe preferred the G43 over the StG44 because it shot the full-power 8mm Mauser, but once its paratroopers tried the StG44 it dropped its opposition. Frontline paratroopers embraced it, even if the Luftwaffe’s ordnance and staff officers looked at it

a bit sideways.

Clearly the goal of the whole MKb42 project was to create a carbine that could replace the K98 entirely. It had to be more than a submachine gun—it had to be a carbine, too. But if it was going to do that, it had to be capable of fulfilling all the various roles demanded of a 20th century military service rifle. Was it accurate enough to be a sniper rifle? Was it sturdy enough to launch grenades? How was it to be used in hand-to-hand combat? Could it take a bayonet? At the end of the war, these questions remained unanswered, and the StG44 was a still a work in progress. Experiments were done with launching grenades. A variant with a scope mount was tried out, but it was dropped to speed production. The Mkb42’s bayonet lug was dropped for the same reason.

Most units got some StG44s, but certainly not as many as they wanted or needed. Some units distributed them one or two per squad, supplementing MP40s rather than replacing them. Others concentrated their allotment of StG44s in assault platoons, companies or battalions as much as logistic circumstances permitted. These assault units, equipped entirely with StG44s and MG42s, used their concentrated firepower to plug holes in crumbling defensive lines or launch shockingly effective counterattacks.

- RELATED STORY: Gewehr 43: Germany’s Garand

To frontline soldiers, the StG44’s qualities were self-evident—it was a carbine and a submachine gun all in one. More than 425,000 MP44s were made, but the problem was in getting them to troops at the front as the German military’s transportation and logistics networks had all but collapsed toward the end of World War II. But where the StG44s showed up in significant numbers, they made an impact on the battlefield—not enough to turn the tide, but enough to make the last six months of the war a lot bloodier, especially on the Eastern Front.

Although the StG44’s impact on WWII can be hard to measure, its influence on the modern battlefield is certainly clear. Apart from its status as the first real assault rifle made in huge numbers and widely issued, its influence can be seen in the AK-47, M16, G3 and FAL. It is the father of all the military assault rifles and the first rifle truly suited to modern war.