I’ve been around the custom shop circuit many times and, in all honesty, the facility at Remington’s main plant in Ilion, N.Y., never fails to amaze me. In fact, my first custom-made rifle was a Remington Model 700 “Custom” in the .25-06 Rem cartridge. I placed my order with the local dealer and then waited for what seemed like an eternity, but finally it arrived. The gun was everything I dreamed it would be, and it shot like all get out!

- RELATED: Glock 22 Gen4 & Remington 870: The Ultimate Street Combo

- RELATED: Remington Completes Its M2010 Contract

As I moved further and further into the shooting sports and writing, I decided to place another order for a dedicated Model 700 in .222 Rem for my woodchucking duties. However, this time I had some madness to my order—I would do a story on the shop and actually go up to New York State for a full day observing and talking to Remington’s Tim McCormack, who is still a good friend of mine. The gun was equipped with fancy wood, ebony caps and all the trimmings. To this day, it still places three little shots in an area smaller than a dime at 100 yards. After that, I acquired a smaller Model 40XR chambered for the .22 rimfire for small-game hunting here in New England.

It was a good experience for me to spend some time at the Remington Custom Shop. For one, it let me elbow up to the artisans there who knew everything there was to know about custom rifles. If you think “multi-tasking” is a buzzword of today, back then one man could inlet a stock, work on the action and put it all together for the customer. Men walked around in their shop aprons, the smell of oil and walnut permeated the air, and wood chips were flying back then. In the past, the Custom Shop was on the third floor I believe; now they are on the first floor of the plant, where all the dust is trapped in huge vacuums and lifted out of the shop. It is a totally different shop—clean, well maintained and organized.

Advertisement — Continue Reading Below

Custom Shop

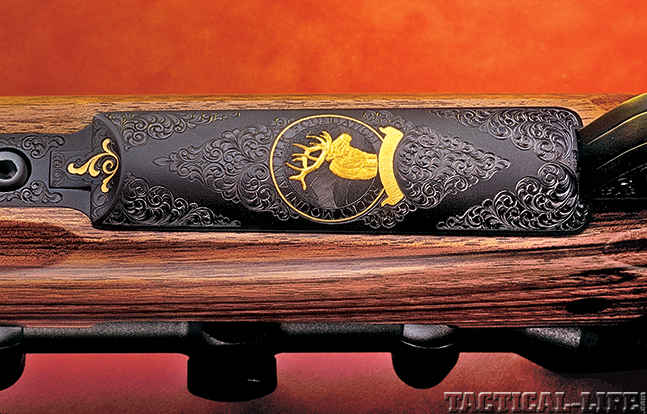

Now, if you think that the Remington Custom Shop only makes pricey, well-decorated guns, you are wrong. The shop is there to support any and all customers, whether you are the average Joe (like me) or some well-heeled oilman from Texas. Sure, you can have gold inlays and super fancy wood, but on the other hand, there are guns that are made to more exacting standards than production guns, and here is where Remington shines. The Custom Shop’s Hunter Grade lineup includes such names as the ABG, Safari KS, North American Custom, African Plains Rifle and one of my favorites, the Model Seven Custom MS (Mannlicher Stock) rifle. Priced from $1,999 upward, they each represent a great value—something you will be proud to have in your battery and hopefully pass on to somebody close in the future.

Advertisement — Continue Reading Below

“My own Custom Shop Model 700 rifle in .222 Rem will shoot under a half-inch or less at 100 yards all day long with handloads …”

Part of the overall picture, all of these lower-priced, custom-finished guns are now available to the general shooting public. I call them “production-custom” rifles, and they include everything from hand bedding and finishing to a wide choice of cartridges, from varmint takers to big-game magnum go-getters. For centerfire fans, the famed Model 700 is now available in a C-grade offering for those interested in small- or big-game hunting with a wide variety of options and cartridges. It is one of my favorites from the Remington Custom Shop.

Advertisement — Continue Reading Below

The 700 Legacy

The Model 700 is unquestionably the flagship of the Remington stable of rifles. Evolving since its introduction in 1962, the rifle has had its share of improvements, but overall the content of the original design is still there. Looking at today’s catalog, you’ll find Remington Model 700s chambered for everything from the petite .17s to the hard-kicking .45 caliber, with stocks that consist of laminates, synthetics and traditional wood. In fact, according to the supervisor of the Remington Custom Shop, Shane Earl, the company offers 56 different calibers to choose from in both right- and left-hand actions in its custom-built guns.

I don’t think you will find a more colorful gun than the Model 700—all 5 million of them, which makes it a prime candidate for any Remington custom work. Led by a team of engineers headed by Mike Walker, the Model 700 followed a natural progression from the past 721, 722 and 725 rifles with a totally redesigned bolt with twin locking lugs and a bolt handle that was secured in its own receiver recess—something that is still with us today. In fact, in a press release dated January 10, 1962, Gail Evans, then the director of sales, announced to wholesalers that “the world’s strongest bolt-action centerfire rifles” were now ready for shipment. With its solid bar-stock receiver, newly designed stock (albeit with impressed checkering) and a tough RKW finish, this gun was ready for the masses.

Advertisement — Continue Reading Below

I assume it was the Remington 700’s potential that lead it into the doors of the Custom Shop. After all, it was chambered for just about any cartridge you could think of, and in 1965 the “D” (Peerless) and “F” (Premier) series of high-grade rifles were introduced. At the time, these guns were priced at $600 and $1,200 respectively, but a few years later, a more reasonable “C” (Custom) model was offered at around $335.

Gun Details

Advertisement — Continue Reading Below

The Model 700 Custom “C” Grade is an edition now in production from the Custom Shop, and it represents a new direction in high-quality guns. From the ground up, the gun is literally handmade and finished, with a stock that rates as a “fancy” American walnut piece of wood. My test sample came with a beautiful wooden stock complete with a feathering pattern that started at the top of the comb and flared back and down towards the toe of the stock, which is what Remington calls a “C-grade” piece of wood. When you order a rifle of this caliber, all stocks meet this high-grade criterion before they are shipped from the factory. The C-grade has about 25 percent figuring, and while the shop does not guarantee any particular percentage of color or grain patterns, it will honestly honor any reasonable request you might have with higher-grade wood as an extra-cost option.

This gun is just a pleasure to look at and hold. Right out of the box, this Model 700 variation just screams quality, from its precise inletting to its overall finish. Each rifle is worked on by hand by the men at the shop, right down to the finest detailing. The satin finish on the wood is butter smooth and worthy of the “custom” name. All of the joints—whether at the recoil pad, the pistol grip cap or the forend tip—are so well fitted that there is no gap where any two surfaces meet.

While this gun came with a classic stock as I had requested, you also have a choice of a high comb (aka Monte Carlo) stock as an alternative, as was the trademark on the famous BDL line of rifles. Both high-gloss and satin finishes are available, with the favorite being a hand-rubbed oil that, according to Shane Earl, “brings the black walnut to life.” The detailing of the stock is the best, and includes checkering that is executed in a point pattern with ample coverage on the pistol grip and forearm. On the former, it covers the entire wrist of the grip, complete with some extended coverage at the base of the pattern. The checkering pattern wraps completely around this gun’s forend, and, like the grip, it’s perfect in every respect. There are no runovers, and the diamonds are impeccably formed and cut after the satin finish has been applied.

Advertisement — Continue Reading Below

Other features abound, giving it the look of a true custom rifle. There are genuine rosewood tips on the forend and pistol grip cap, both without spacers. There is a cheekpiece on the left with detailing so fine that you can almost cut your finger on the sharp leading edge! In addition, the cheekpiece can be finished to include a shadowline running up and over the stock if desired. In short, looking at the literature and talking to the men at the shop, I don’t think there is anything they can’t do to your rifle. To complete the stock, sling swivels and a Remington recoil pad with a black spacer are installed, with the working gunsmith signing off with his name or serial number in the barrel channel.

All of the Remington Model 700 Custom “C” Grade’s metalwork is highly polished and blued. Barrels are available in 24- (standard) or 26-inch lengths for magnum cartridges, and the rifles come without sights. The gun is presently available for any standard caliber, with either a short or long action depending upon the overall length of the cartridge. The action is typical Model 700 fare, and it includes a twin-lug locking system with a guide slot on the right-hand lug to aid in moving the bolt in and out of the breech. This mates with a polished raceway, and since the bolt does not contact the follower, it is now refined to the point where it moves effortlessly within the confines of the receiver. On the bolt face, you will find a blade-type extractor and a plunger ejector. The bolt knob is checkered, and the action is epoxy bedded within the stock.

The gun is fitted with a BDL-styled triggerguard and floorplate. On the right-hand side, behind the bolt knob, is the two-position safety, which allows the shooter the convenience of unloading the gun with the safety on. One of my samples over the years was chambered for the .22-250 Rem; the trigger broke at 4.75 pounds without even a hint of slack. Overall, the .22-250 Rem rifle is one of my all-time favorites when I go looking for woodchucks here in the Northeast.

Advertisement — Continue Reading Below

Range Time

A Model 700 Custom “C” Grade I tested a while back pulled in groups that hovered around 1 MOA at 100 yards, with Remington’s 55-grain hollow points clustering into 0.75 inches on a cloudy, cool and windless day. Federal’s 40-grain hollow points and Winchester’s 50-grain Ballistic Tips each placed three rounds into 1-inch circles consistently without any effort on my part. My own Custom Shop Model 700 rifle in .222 Remington will shoot under a half-inch or less at 100 yards all day long with handloads consisting of 21 grains of IMR-4198 powder behind a Sierra 52-grain HPBT bullet.

Advertisement — Continue Reading Below

For those shooters and hunters looking for something different in the way of firearms, the Remington Model 700 Custom “C” Grade is the way to go. They are good-looking, and for the price, this is definitely a step above a typical production rifle. If you are thinking ahead, this “C” Grade is popular, and presently the waiting time is around six to eight months.

Finally, before you put down your hard-earned money, I would check with the Remington Custom Shop for extras. Again, Shane Earl told me that there are choices in wood, fluted or non-fluted barrels, muzzle brakes, custom grip caps and forends, checkering patterns, hand-cut engraving, and much more. According to Shane, “If you can think it and it’s available, we can make it happen on your ‘C’ Grade rifle.” To me that says it all.

For more information, visit remingtoncustom.com or call 315-895-3288.