The word “master” is thrown around a great deal these days, associated with everything from sports tournaments to retail brands. Against a constant thrum of marketing hype, of ad and sales copy, and cynical consumer commentary on the numerous commercial offerings branded the work of so-called masters, it’s possible forget those living masters working today. Among bladesmiths, one such master is knifemaker Kiku Matsuda, renowned in the custom knife industry for the grinding and polishing work that he does completely by hand. Matsuda’s fixed blades straddle the line between art knives and custom tacticals, and have earned him a deserved reputation among the best grinders in the world.

Meet Matsuda

According to one source, Matsuda’s father ran a small workshop in the famed cutlery production center of Seki, Japan. Matsuda began work there at just 15, giving him more than 40 years of experience designing, grinding and polishing knives. Chris Cashbaugh, marketing manager at SOG Specialty Knives & Tools, explains that this is part of what makes Kiku Matsuda’s work distinctive, setting him apart as a maker of tactical, custom blades that are also artistic.

Advertisement — Continue Reading Below

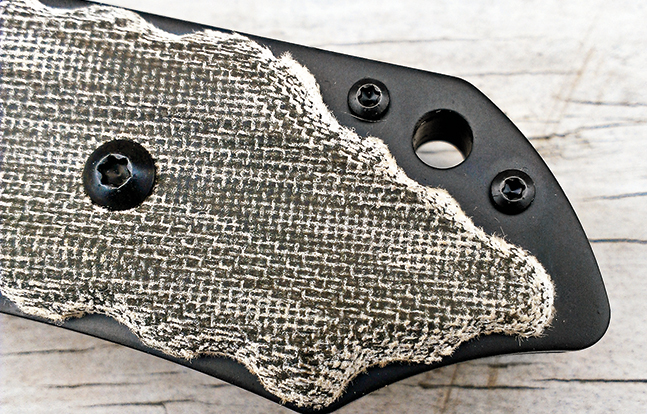

“The cool thing about Matsuda,” Cashbaugh said, “is that he does all of his grinding by hand and by sight. He has some basic jigs to cut out the blades, but all the bevels on his custom knives, they’re all done by hand and by feel. He also does mirror polishing and this cool acid etching texture on his blades…and he’s known for his scalloped Micarta handles. These are some of the cool things that set him apart. His knives are very visually stunning. They’re really good works of art.”

“The performance of both knives is enhanced by how comfortable they are. All the curves and angles are just right to make them feel joined to the palm.”

Working with his son, Masayuki, Matsuda has built a reputation for unique tactical fixed blades that boast excellent durability, unique aesthetics and Matsuda’s hamaguriba, the “clam-shaped” convex edge found on Japanese katana. His steel of preference is high-end OU-31. All of his previous knives have been fixed blades. So how did this particular custom maker end up partnering with SOG to produce his first-ever folding knife designs?

Advertisement — Continue Reading Below

SOG Collaboration

“I think it was in 2008 that we were introduced to Kiku Matsuda through one of our Japanese suppliers,” explained Cashbaugh. “As you know, there’s a big trend in the knife industry to produce collaborations. A custom knifemaker will make a knife, and the manufacturer will take that, make some modifications so the knife is mass-producible, and then offer a production version. You saw that previously with our Brous ‘Snarl’ and ‘Growl’ collaborations with maker Jason Brous.”

The company approached Matsuda about producing a limited-edition run of knives. When Matsuda agreed, he and SOG’s founder, Spencer Frazer, sat down to work out the design. The result was based on SOG’s SEAL Team knife, and limited to a run of 100 pieces, which Matsuda produced in his shop. It won “Collaboration of the Year” that year; limited runs of a collaboration dagger and tanto blade followed, again held to 100 pieces and handmade by Matsuda. “These were ‘reverse collaborations,’” said Cashbaugh. “SOG and Kiku designed the knives, and Kiku produced them. They were fairly expensive.” But SOG and Matsuda were not content to limit their work together to just these short runs of handmade blades.

Advertisement — Continue Reading Below

“He’s always wanted to produce a folding knife,” Cashbaugh said of Matsuda, “but as a custom knifemaker, you don’t necessarily have access to all the same volumes and materials and ways of manufacturing. Folding knives are infinitely more complicated than fixed blades. These are the first folding knives that Kiku Matsuda has designed.” SOG has, in turn, worked with Matsuda to offer these as production folders, in what Cashbaugh called “the best spirit we can of his aesthetic.”

“It’s a Kiku knife in form and function, produced by SOG so it’s affordable for everyone.”

Both the large and small SOG Kiku folders have blade shapes and handles reminiscent of Matsuda’s fixed blades. Several other touches intended to evoke Matsuda’s work have been incorporated in the designs. “We’ve kept the same linen Micarta for the handles that Kiku uses on all his knives, so you keep that same family look,” said Cashbaugh. He further explained that the stainless steel liners, which extend beyond the handle slabs, are also intended to mimic the look and feel of some of Matsuda’s fixed blades.

Advertisement — Continue Reading Below

At the same time, SOG worked to keep the knives affordable so that they would be accessible to a greater segment of the market. “We wanted these to be successful,” Cashbaugh said, “so we’ve not used the same high-end steel for the blades, which would be prohibitively expensive. Instead, we went with our tried-and-true AUS-8 stainless steel. We have a very good track record with that steel. We’ve been using it for years; we know how to heat-treat it well. That’s where some of the SOG heart comes in. It’s a Kiku knife in form and function, produced by SOG so it’s affordable for everyone.”

Field Test

Both the large and small Kiku folders are liner locks with 0.16-inch-thick, AUS-8 steel blades, ground on both sides to a very sharp edge. (This edge is not convex, as some buyers might assume, but the typical edge found on SOG folders.) The Rockwell hardness is listed at 56 to 58. The smaller blade is 3.5 inches long and weighs in at 4.2 ounces; the larger is a substantial 4.6 inches and weighs 7 ounces. Each blade is equipped with dual graduated thumb studs.

Advertisement — Continue Reading Below

Out of the box, these are visually impressive knives, as one would expect. The green linen Micarta handles are attractive, textured for an excellent grip and feature both a prominent groove and ergonomic scallops. The resulting traction offered is much appreciated in so comfortable a handle. Both the large and small Kiku sit naturally in the hand in a forward grip. A reverse grip is comfortable with the large folder, while slightly more awkward but entirely workable with the smaller.

The low-profile pocket clip had good tension out of the box and can be removed if desired. A second pocket clip, shaped for the opposite side of the handle, is also provided, but both clips are configured for tip-up carry only. The protruding liners feature a lanyard hole in the butt of each knife.

Both knives open smoothly and lock positively. The liners engage fully, with room for wear, and there is no blade play. The blades pierce and cut with great power. Both knives made very short work of a heavy, rubberized and waterproof military-surplus backpack, slicing through the heavy synthetic material with ease. Afterwards, they would still cut paracord with a minimum of fraying, while they both penetrated deeply in stacked cardboard and through multiple layers of heavy plastic sheeting. The performance of both knives is enhanced by how comfortable they are. All the curves and angles are just right to make them feel joined to the palm.

Advertisement — Continue Reading Below

The Future

Chris Cashbaugh spoke enthusiastically of the new Kiku line and what it offers consumers. “The big thing,” he said, “is that the manufacturing quality is in line with every one of our knives. The SOG Kiku knives can be used everyday but have their roots in a tactical aesthetic and function.”

The Kiku folders are also just the beginning. This year, at a large industry trade show, the company unveiled plans for a line of Kiku Matsuda-designed fixed blades as well. “With these,” promised Cashbaugh, “you’re getting the influence and styling of Kiku with the manufacturing base, knowledge, warranty and accessibility of SOG. You’re getting a really cool-looking, stylish knife that’s definitely more reasonably priced, and it’s going to have a company standing behind it for a long time.”

Advertisement — Continue Reading Below

For more information, visit sogknives.com or call 425-771-6230.