Customers can order customized engraving on the slide flats of their Night Shrike.

Starting a new company to manufacture 1911 pistols makes as much sense to me as starting a new AR-manufacturing company—the market is just too saturated with companies building the same style of guns and chasing the same dollars. Matt Burkett of Predator Tactical has a plan and begs to differ, however.

While many readers will recognize Matt Burkett as a guest instructor on the History Channel’s popular Top Shot show, he’s achieved worldwide success as a pistol and 3-Gun competitor with a list of titles and championships that are only surpassed by the numbers of elite military and law enforcement units that he has trained.

Advertisement — Continue Reading Below

The Night Shrike is a 4-inch defense gun with an alloy frame.

“My philosophy is to do things well and do them right, and then back it up with unmatched customer service. After all, it’s my name and reputation on the company. Scot Towner and Lynn Harrison convinced me that we could do something right that no one else has been able to do. Between the two of them, they have 25 to 30 years of experience building 1911s,” said Burkett.

I was at the Tempe, Arizona, manufacturing facility of Predator Tactical, attempting to discover what would set this new brand apart from other 1911 companies. “Look,” said Burkett, “I don’t want to build 10,000 guns a year. I’ll be happy building just 300 to 400 guns and being able to maintain my level of customer service.”

Advertisement — Continue Reading Below

Weighing just 30 ounces, the Night Shrike epitomizes what every carry gun should be.

The topic of my meeting this day with Burkett was to discuss Predator Tactical’s newest pistol, the Night Shrike. It’s a 4-inch barreled 1911 pistol built on an alloy frame for weight savings and incorporates the new Predator Tactical magazine well.

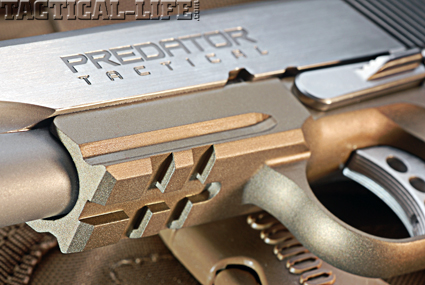

The polished stainless steel parts contrast nicely with the matte frame.

Advertisement — Continue Reading Below

Gun Details

As soon as I picked it up I knew that I was holding something special. It’s a gun that possesses the perfect balance and a feeling of quality. I handled five different Night Shrikes at Predator Tactical and each possessed an amazing degree of fit and finish. The frame-to-slide fit is absolutely impeccable, yet the slide cycled as if it rode on ball bearings. The ambidextrous thumb safeties, beavertail and slide stop were all fit with the same flawless precision.

I had a chance to speak with Predator Tactical’s production manager, Scot Towner. According to him, all of the Night Shrike’s major components come from Wilson Combat’s Bullet Proof line. “The parts are built using substantial machinery by people who know what they are doing,” said Towner.

Predator Tactical’s TacWell doubles the size of the mag well without adding length or girth to the frame.

Advertisement — Continue Reading Below

Towner is no slouch with a CNC machine, either. In fact, he does most of the machining at Predator Tactical. While you may have visions of artisans in leather aprons filing frames to fit the slides, Towner uses a different approach. “Our competitors cut the frames to fit the slides. That is the exact opposite of what we do. Scot CNC machines the slide to fit the frame and then hand laps them,” Burkett said, handing me a gun to check the flawless frame-to-slide fit. “We inspect them right here, and if this fit is not right, it’s certainly not going to get any better by adding other parts to it.”

Predator Tactical serrates the top of the Night Shrike’s slide to reduce glare.

Towner told me that he uses a CNC machine for its precision cuts and ability for repeatable accuracy. Other companies fit the barrel feet with a hand cutter, but Towner built his own fixture so that he can cut them in his CNC machine. Burkett said, “There’s another custom gun company that looks like they have a 7-year-old fit for the barrel feet. They cut the barrel feet at a 45-degree angle to achieve a smooth unlock. That’s not how you achieve a smooth unlock—that’s how you ruin the delayed unlocking!”

Advertisement — Continue Reading Below

The Night Shrike uses a Wilson Combat bushing-less bull barrel and material is relieved from the inside of the slide for a precision fit. That same fixture is also used to trim the barrel hood.

Checkering is included on the Night Shrike’s frontstrap. Machine cut at 30 lines per inch, I could not find a single flat diamond or overrun on any of the shop guns. Once all of the parts are fit to the frame, the gun is stripped and blasted with Ziconia, a non-embedding ceramic media that doesn’t shatter like glass beads and smoothes the surface of the aluminum without freckling. Customers have a choice of colors for the frame. While I was in the Predator Tactical manufacturing facility, I saw varieties of desert tan, OD green and matte black.

Predator Tactical machine-checkers the Night Shrike’s frontstrap at 30 lines per inch.

Advertisement — Continue Reading Below

Perhaps the most eye-catching feature of the Night Shrike is its new Predator TacWell. PT’s magazine well is cut flush with the frame yet doubles the area of the chute. The patent-pending part requires the frame to be cut on the sides and the part slides on and is anchored with the mainspring housing pin. Once attached, the TacWell becomes part of the gun and is rigid without any play. The mag well opening is deeper in the back and requires a mainspring housing cut specifically for this mag well.

Predator Tactical’s TacWell supplies the shooter with a mag well twice the size of a normal mag well for quick and sure magazine changes, yet the outside diameter of the mag well is not any bigger than standard frame dimensions, making it perfect for serious defense work.

Customers can order their Night Shrike with the newest set of Crimson Trace Masters Series grips.

Burkett specified the part be made from stainless steel to protect the softer aluminum frame. The polished stainless steel part contrasts nicely with the matte finish there. The ambidextrous thumb safeties and beavertail grip safety are brightly polished stainless steel, too. The fit of the beavertail is impeccable. It moves smoothly and possesses less than a hair’s thickness between frame and beavertail. Lynn Harrison is in charge of cosmetics and fit of these parts. He’s also the man responsible for the super crisp 3-pound trigger pull the Night Shrike possesses.

Predator Tactical outfits the Night Shrike with a full-length recoil spring guide. Its bushingless barrel design makes it easy to disassemble.

Predator Tactical gets their fire control parts (hammer, sear, disconnector) from Extreme Engineering. The wire EDM parts are popular with the competition market but are also perfect for custom defense guns. Harrison says that the parts are so consistent that he can get a perfect trigger pull every time.

PT serrates the top of the slide to reduce glare and the three middle lines are cut a little deeper to accentuate the center of the slide. Customers have their choice of sights. PT uses Tripp, Dawson and Heine rear sights and can outfit the Night Shrike with a tritium, fiber-optic or plain front sight.

The Night Shrike’s light weight and features make it ideal for a custom defense handgun.

Burkett’s thought here is to offer sights that the customer can best utilize. Burkett said, “One older customer bought the Night Shrike from a dealer’s shelf and called and asked if he could make the trigger pull heavier and also wanted a fiber-optic front sight that he could see better. He sent us the gun and we made the changes at no charge. We’re not a rigid assembly line here at Predator Tactical.”

The Night Shrike’s ejection port is lowered and flared, and PT craftsmen break all of the sharp edges—but not so much that the gun doesn’t have a nice sharp, detail-filled appearance. All engraving is CNC machined and customers can have virtually anything engraved on the slide flats. In fact, I saw several interesting and humorous themes while I was in the PT factory.

An alloy frame with a tactical rail is used on the Night Shrike.

The grips are machined from rugged G10 Micarta material and cut to fit the PT TacWell. They have colors to match all of the different frame colors. While I was in the shop, Burkett showed me a new generation of Crimson Trace Master Series grips that had been fit to a Night Shrike. The new grip does not require shortening the weak-side safety.

Performance

Burkett fires and sights in every gun produced in his shop. According to Burkett, “Every gun has a minimum of 100 flawless rounds through it when we ship. I’ll do at least two cycles with every magazine. So, if a customer orders 10 magazines with his gun, I’ll fire a minimum of 160 flawless rounds through it. People rely on our guns for competition and real-world defense and we can’t take a chance that they’re not right. I want them to be able to go shoot a match or start carrying the gun the day they get it with complete confidence that gun will help them win a match or survive a deadly encounter.”

The Night Shrike is available with a choice of front sights. This pistol was outfitted with a fiber-optic front sight.

Burkett emphasizes, “These are all custom guns. You can have them anyway you want them and we can put your name on them. We sometimes try to build forward; in essence, we get the gun to the point where the customer wants to customize it with engraving or sights etc.” So turnaround time for a custom gun, built on the Night Shrike template, is very quick.

The Night Shrike comes with five magazines, a range bag and shirt. Suggested retail starts at $3,950. Burkett says that he’s received criticism from those who don’t understand how expensive a custom-built handgun can be. Burkett says, “That’s OK—not everyone can drive a Ferrari, either.”

Predator Tactical offers the Night Shrike in a myriad of colors.

The Night Shrike comes with a lifetime warranty and the people who buy Predator Tactical guns will shoot them a lot. So if you have a breakage after 100,000 rounds, Burkett will happily replace the part and make it like new. The Night Shrike also comes with a free personalized shooting lesson or a discount off of one of Burkett’s classes.

Predator Tactical’s Night Shrike is expensive at $3,950, but as Burkett notes, “Not everyone can drive a Ferrari, either.”