Ever since the Ruger Redhawk was first introduced back in 1979, there have been many requests for a 4.2-inch version of the beefy revolver. Ruger’s offered us 5.5 and 7.5-inch barrels, in all three of the major magnum calibers and the .45 Colt, but never a standard factory 4.2-inch barrel in any of those calibers. If you were a fan of Ol’ Red and wanted a shorter tube, you had to have one whacked off by a gunsmith or custom shop, as I did on my first Redhawk a while back. A worthwhile investment, in my opinion, to end up with one of the strongest .44 Magnum double-action revolvers on the market in a much more packable package, it was also a relatively expensive investment. Besides the cost of the barrel job, some sort of replacement front sight had to be attached, and that

involved more custom work, along with custom prices. Why Ruger never gave an ear to those requests has always been a mystery to me, but the good news is that they’ve finally listened to the market, and some persistent internal nudging by Ruger’s Media Relations Coordinator. You can take your well-worn credit card to your local neighborhood gunshop right now and buy a stainless, factory 4.2-incher. No custom fees, no shipping charges, no 12-month wait to get it back. Ruger’s done all the work for you, and this is the Redhawk they should have made 27 years ago. If my sample is representative, and Ruger swears it is, you’re gonna like the Ruger Redhawk .44 MAG.

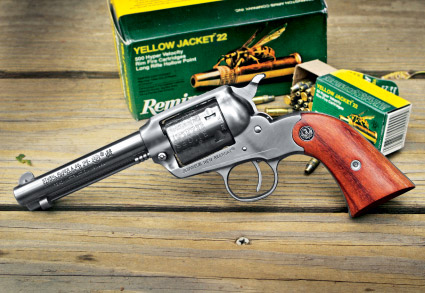

Ruger Redhawk .44 MAG Details

Most Ruger fans know the story of the Redhawk. It was Ruger’s second entry into the double-action centerfire revolver field. Unlike S&W’s N-framed .44 Magnums, which had been mostly upgraded in heat treatment and metallurgy to contain the pressures in a design never intended for them, the Redhawk was engineered from the get-go for that caliber. Bill Ruger’s design team started from scratch, and with a clean sheet of paper on the drawing board that allowed them to build strength and durability around the cartridge instead of modifying an older design to fit it, the result was an innovative and brick-built DA revolver that not only handled standard .44 Magnum pressures easily, but kept on doing so long after any other DA .44 Magnum revolver on the scene either gave up the ghost or required extensive rebuilding.

Advertisement — Continue Reading Below

Design

The massive frame resists stretching and torquing, the front crane latch creates a positive and stronger cylinder alignment and lockup; the forcing cone is virtually unbreakable, and it is possible to blow one up, but with the Redhawk’s thick chamber walls and offset locking notches you have to work up to some truly idiotic levels with your handloads to do it.

The Redhawk went to the field in large numbers, in hip and shoulder holsters with iron sights and glass, and created a reputation for itself as the gun that “came through.” Even though few people use the .44 Magnum as a target gun (except the metallic silhouette shooters), those who did throw a lot of lead through their .44 Magnums quickly found out which DA revolver was the one to have for high volume “wrist busting.” Also, since the beginning, strength and durability aside, the Redhawk has drawn three criticisms: size, trigger and grips. Back when Elmer Keith was hitting the trail on a hayburner, barrel length wasn’t as much of an issue, as he often noted.

Today, when most of us get where we’re going by car or truck, and don’t even know which end of a horse the hay goes in, it’s a different matter. A 7.5-inch barrel hanging on a belt just doesn’t sit well on a truck seat, and it’s a nuisance to be always strapping on or off when you get in and out if you take that route. The alternative was one of the hunting shoulder holsters, but they can be awkward to use and access under coats and so on. Even a 5.5-incher can drag and dig on a car seat.

Advertisement — Continue Reading Below

Internal Mechanism

The original Redhawk’s internal mechanism was different from both Ruger’s Security-Six series and DA revolvers by other makers in that it used a single coil mainspring to power both the hammer fall and trigger return. As a result, double-action pulls were stiff with this innovative action design, and nowhere near as smooth, light, and crisp as S&W’s .44 Magnums. The Redhawk was sniffed at by those used to the superior trigger pulls of the Smiths. In a DA revolver with a hammer spring and separate trigger return spring, it’s possible to work on the trigger, lighten and smooth the DA pull, and clean up the SA trigger break. But,

with the Redhawk, modifying the single main spring to give a lighter DA trigger pull also affected the energy transmitted to the hammer, and frequently ended up causing more clicks than bangs when primers weren’t struck hard enough to ignite. There was only so far the DA pull could be taken while still retaining reliable ignition, and it still was nowhere near the fabled “glass-smooth” triggers on the Smiths.

Grips

The original factory wood grips have been carried by the factory since their introduction. I recall earlier writers at the time mentioning how well they fit the hand, and how well they functioned under recoil. When I got my first Redhawk, one of my immediate impressions was how well those grips did not fit my hand, and how well they did not function under recoil, particularly with heavy-for-caliber .44 Magnum loads.

Obviously, there was some difference between those writers’ hands and mine. And, I’m not the only one; many shooters do just fine with the Redhawk factory wood, but many don’t, and even though there’s been several aftermarket grips in various configurations and materials available over the years, the fact remains that the Redhawk gripframe is a relatively large one, and as Hamilton Bowen told me when discussing my custom Redhawk 4.2-incher a while back, some people just never can find a grip that fits both gun and hand well.

Advertisement — Continue Reading Below

Speaking from personal experience with a Bowenized Redhawk and Super Redhawk, both with 4.2-inch barrels, the package just makes the big gun more portable. The shorter tube stays out of the way in and out of vehicles, and also comes out of the holster quicker, if speed becomes an issue. Far fewer shoulder contortions in clearing leather with a 4.2-incher than a 7.5-incher. It also reduces the overall weight of the big boomer, which can help in holding aim on a deer as well as in hiking your tired body up the hill to find one.

Sight Radius

The sight radius is reduced, true, as well as velocity, but I consider it a very equitable trade-off. Rather than carrying over the normal front sight base of the Redhawk that allows for user-removable optional sight blades, Ruger took the less expensive path and fitted a black pinned blade with a red-orange insert in the shorter barrel. The company says it has “no plans” for any other front sight options now, and I’d suspect they took the simplest route in testing the market to see if the gun will sell. If it does, and it should, they may change their minds down the road. Rear sights are standard adjustable white outline.

Trigger

I don’t know how they did it, and believe me, I tried to find out, but the trigger on my Ruger Redhawk .44 MAG (yup, we’ll cut to the chase and say right here I refused to return the sample) is nothing short of disbelievable. Two gunsmiths at my dealer’s, and I, were all incredulous about this gun when I first picked it up. The double-action pull is lighter than either of my Bowen Reds, one of which was a Super Redhawk project commissioned partly to get me a better trigger than he could do with the standard Redhawk, which he did.

Advertisement — Continue Reading Below

It’s smooth, there’s zero creep in single-action and zero overtravel, and it’s quite simply the best DA trigger I’ve ever encountered on a Ruger Redhawk. It even rivals the DA pull on a customized GP100 .357 Magnum that cost me a fair amount to get done. This is a major improvement for Ruger, and you get it right out of the box. The SA pull after my bench session is down to slightly under 6 pounds, which could be better, but I’m not complaining.

Grip

Grips are a very personal thing, and that’s what keeps the successful aftermarket grip makers in business. A grip that may feel like it was crafted in Heaven to one shooter may feel like a torture device from Hell to another. In shooting a heavy kicker with heavy loads, the trick is to find a combination of design and material that handles recoil efficiently, and positions the gun in hand so that the pivoting that comes with the blast doesn’t cause undue pain, or even damage to the hand. I find with the Redhawks that I need a grip that situates the gun slightly higher in the hand. Too low, with the web in contact with the prawl (top of the gripframe), and it literally tears skin at the base of my thumb with the Garrett 330-grain Hammerheads that my Redhawks carry in high timber.

Hogue’s Rubber Tamer Grip, standard on the short-barreled Alaskan Super Redhawk variant, is the best fitting grip, bar none, I’ve found for the Super Redhawk. It’s on both my Super Red and GP100 now, because using the abbreviated grip strut of the Super and GP frames, it’s possible to reduce the overall grip dimensions to fit medium-sized hands in a way that’s not possible with the conventional Redhawk gripframe, without paying for a custom round-butting modification.

Advertisement — Continue Reading Below

Backstrap

With its straighter backstrap, enclosed (no exposed steel) construction, palm swell, and three finger grooves, it positions the gun high to protect the web of my hand and anchors it thoroughly under substantial recoil. It’s a masterpiece of design and execution, and I was wondering how the factory 4.2-incher would be set up from the factory, gripwise. I knew they couldn’t beat the Rubber Tamer Grip, because adapting it to the Redhawk would leave

it too big and ungainly for most hands, but Hogue came through again. Their Bantam line for smaller revolvers uses a snap-on approach, with no grip screw,

and Hogue developed a Bantam version for the Redhawk .44 MAG. Also made of soft rubber, the grip slides on using the Hogue “double wedgie-widget” supplied, and stays put securely. An open-backed style, with exposed steel backstrap to keep dimensions down, this Bantam features pebble-grained palm swells, three finger grooves, and a bottom groove extending below the front of the steel gripframe. It’s a hand-filling proposition without being too hand filling, again positions the gun high, and allows a good trigger reach for most medium to large hand sizes. It also anchors the gun tight, and that’s another important feature when shooting bear-blasters.

Shooting Impressions

This one intrigued me so much that I delayed the lineup of other scheduled projects and worked it in as close to immediately as possible. I picked up the Ruger Redhawk .44 MAG on a Friday, and shot it with six different commercial loads in a foot of snow at 19 degrees on the following Monday after four-wheeling it up the hill to the gravel pit.

Ammo

Randy Garrett’s 330-grain Hammerheads, the heaviest of the loads tested, took first place, with a six-shot string off the Pistol Perch at 25 yards that measured 1.63 inches. Oddly, his lighter 310-grain Defenders didn’t do quite as well, although holding under 3 inches was more than acceptable for any job I’d put them to.

Advertisement — Continue Reading Below

Both loads are “SuperHardCast,” as Randy puts it, with the 310s producing about 80% of the penetration of the full-bore Hammerheads, and much less recoil. Randy designs the 330s strictly for the Rugers (too long to fit Smiths) and takes full advantage of the Ruger’s strength to drive them hard. His 310s are short enough to fit other .44 Magnums, and with markedly less recoil they’re much faster on follow-up shots. Both loads are intended for maximum penetration, and all reports indicate their reputation is well deserved.

I favor heavier-than-standard loads for magnum handgun calibers. Since I use the .44 Magnum for defense instead of hunting, I ran down from 330, to 310, 300, 275, 250, and 240 grains in the pit. The shiny Ruger Redhawk .44 MAG seemed to prefer the heavier bullets. The Hornady XTP load would be my choice in a jacketed bullet where deep penetration with controlled expansion is the goal, and for hunting uses on moose and lesser animals the Remington and Winchester jacketed loads should bring home the meat, while the Gold Dot should be good deer medicine.

| Load | Accuracy |

| Garrett 330 Lead Hammerhead | 1.63 |

| Garret 310 Lead Defender | 2.75 |

| Hornady 300 JHP XTP | 1.94 |

| Remington 275 Core-Lokt JHP | 2.06 |

| Winchester 250 Partition Gold JHP | 1.94 |

| Speer 240 Gold Dot JHP | 3.38 |

Advertisement — Continue Reading Below

Trigger Performance

Back to that trigger. Being a skeptical sort on occasion, I confirmed with Ruger that my gun came to me first. Some makers have a pool of “Writers’ Guns” that they send out for evaluation on request, with four or five guns being recycled among various writers as requests for T&E samples are received. Not the norm, but it does happen now and then with a gun where there may only be a handful of shootable samples in existence, and the company wants to get samples out for review.

Very rarely, a writer may do a minor tweak or two to fix a pre-production glitch, modify a scope mount, and so on, while he has it in hand before returning it. I wondered if this trigger had been slicked up outside the factory under such circumstances, but it came straight to me. Nobody else tinkered with it; it’s just the way it left the factory, and that’s what Ruger says everybody can expect on this gun.

If a defensive gun doesn’t produce a bang every time you tell it to, the meat you lose may be your own. Relative to the above mention of light primer strikes on lightened Redhawk triggers, during the test session the gun lit up every one of the approximately 75 rounds fired perfectly, and that included single-action and double-action shooting. CCI primers are typically the hardest among the US brands, and the Redhawk had not a single misfire with them, or any of the others. Whatever Ruger’s doing with this trigger, it’s working. The grips? Ouch on the 330-grain Hammerheads, even with a pair of Uncle Mike’s shooting gloves on in deference to the temperature.

Handling

Everything else was tolerable, and at the end of the session I touched off a full-cylinder of those 330s in one-handed single-action mode with bare hand just to show off how tough I am. After due consideration, I decided there was no point in trying to impress anybody with my toughness in trying another six. The Bantam grips obviously can’t cushion as well as the Rubber Tamer Grip, since the steel backstrap’s sitting against the skin, but they do a surprisingly efficient job considering the gripframe parameters. The shorter barrel allows for more muzzle flip, and you need a good hold on the gun.

Advertisement — Continue Reading Below

The Bantams give it to you. Otherwise, my only criticisms of the Ruger Redhawk .44 MAG shorty are the usual sharp hammer spur edges, and the front sight insert. It’s visible, but would be more so in a wider range of lighting conditions with a brighter orange material.

Specs

Caliber: .44Magnum

Barrel: 4.2 inches

OA Length: 9.5 inches

Weight: 47 ounces (empty)

Grips: Hogue one piece rubber

Sights: Red rampert insert front, micro-adjustable white outline rear

Action: DA/SA

Finish: Satin stainless

Capacity: 6-shots

MSRP: $1,379