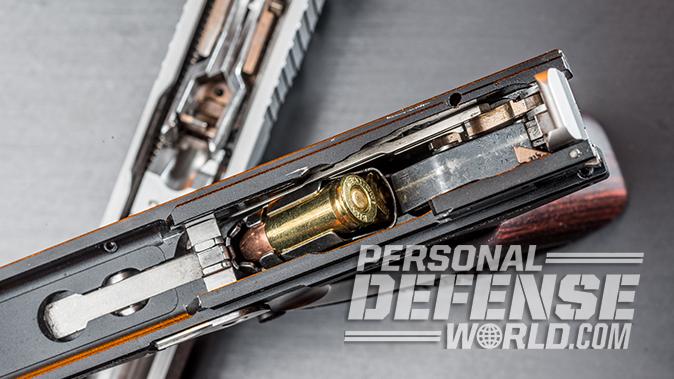

It was at the 2008 SHOT Show in Las Vegas that I first ran across the Boberg XR9 pistol. I was immediately attracted to the semi-auto’s unique profile. It was a bullpup design, meaning the trigger sits in front of the barrel’s chamber, giving the gun a decidedly abbreviated look. It utilized a rotating barrel lockup and was a hammer-fired, double-action-only (DAO) design. But perhaps the most radical design feature of the XR9 was its reverse-feed mechanism, which utilized a claw to remove the cartridge from the back of the magazine and then lift it for smooth chambering as the slide moved forward.

Despite its stubby appearance, the gun possessed a barrel 3.35 inches in length—long enough for most defensive loads to build effective velocity. It had a unique balance, with the bulk of the gun’s weight positioned directly in the shooter’s grip, with a 7+1 capacity, and it weighed just a couple ounces more than a pound. The XR9 also possessed an innovative small-diameter recoil spring that made racking the slide extremely easy. As I held the gun and examined it, I felt like I was either looking at the future of defensive handguns or an oddity that time would forget.

During my meeting with Arne Boberg of Boberg Engineering, he told me the gun existed only as a prototype, and he was looking for financial backers. I sporadically checked Boberg’s website over the next couple years to see if his XR9 was in full production. But I eventually forgot about this interesting handgun.

Advertisement — Continue Reading Below

Bond, Gordon Bond

That is until 2016, when I was at a writer’s event and Gordon Bond of Bond Arms unveiled the Bullpup9. I immediately recognized it as the old Boberg XR9 and was excited to learn that Bond had purchased the company and was intent on putting the gun into production. It was then I learned that Boberg’s problems weren’t only finding financial backing for the gun. In fact, there were also several design issues that prevented it from becoming widely accepted as a defensive handgun. Only 2,700 pistols were produced before Bond acquired the company.

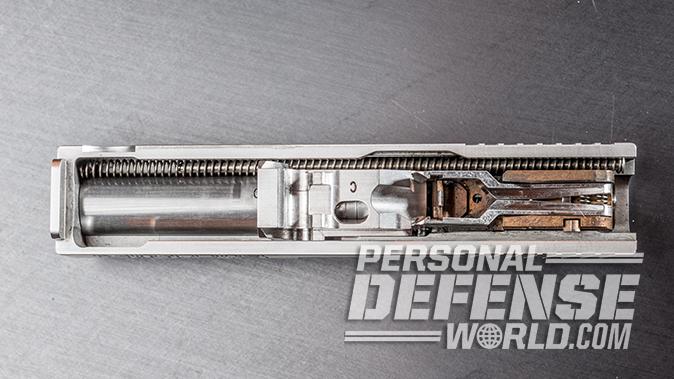

Gordon Bond told me, “The first time I disassembled the gun, I got black anti-seize grease all over my fingers. Every gun guy I know will wipe that grease out of the gun, and it will stop functioning. Even firing a few magazines heats the gun up enough where the grease will melt and the functioning will cease. I thought to myself, ‘That grease has to go!’ So, we tried coating the barrel with electroless nickel-Teflon, and that solved the problem. Boberg had recommended a 500-round break-in, and most people won’t ever fire that many rounds through their gun. The new coating eliminates the excessive break-in.”

Advertisement — Continue Reading Below

Another problem related to the reverse-feed design is that sometimes the slide’s velocity creates enough G-force that it separates the bullet from its case. Bond solved part of this issue by adding weight to the slide to slow its velocity. The other part isn’t as easy to fix. According to Bond, “Most aluminum-cased ammunition doesn’t have much of a crimp, and the bullets will separate from the cases and tie the gun up. We’ve done extensive testing and posted an approved list on our website.

Ammo

As long as people stick with that list, their Bullpup9 will work really, really well. Most ammo is usually only being pushed forward and the crimp becomes less critical, but the reverse feed system is a whole different animal. Hollow points designed for defensive use usually have ample crimps. We hardly have issue with most self- defense loads—it’s usually the ball ammunition that causes us problems. One range load that works very well with our gun is Winchester’s ‘white box’ 115-grain FMJ rounds.”

A Closer Look

I recently had the chance to visit the Bond Arms factory in Granbury, Texas, and see exactly how the Bullpup9s are manufactured. The frame is machined from a billet of aircraft-grade 7075-T6 aluminum alloy. Nearly 90 percent of the material is removed in the machining process, which takes approximately 30 minutes. The slides are machined from 416 stainless steel, and even though Bond owns some very expensive precision robotics, there is still plenty of handwork performed on every pistol. While Bond tries to do as much as possible in-house, the frames are sent out for anodizing and the barrels are sent to another facility for the electroless nickel-Teflon coating.

Advertisement — Continue Reading Below

Because of the bullpup design, the pistol possesses a very useable 4.5-inch sight radius and sights large enough to present a good solid sight picture. The sights are set up in the usual three-dot arrangement, which I had no problem seeing during my range time with the Bullpup9.

The Bullpup9 only possesses two external controls: the magazine release and the takedown lever. The magazine release is located in the usual Browning-inspired location where the triggerguard meets the frame; it is not ambidextrous. Just above the mag release is the takedown lever, which is extremely low profile in design, and the grip has been relieved to accommodate its arc. This part also pulls double duty as a slide lock. If you pull the slide all the way back and move the lever 45 degrees, or straight up and down, it will hold the slide to the rear.

Disassembly

Disassembly of the Bullpup9 is easy and doesn’t require any special tools. After removing the magazine and clearing the chamber, remember to rack the slide multiple times in case there is a cartridge in the claw. Pull the slide all the way rearward and rotate the takedown lever to the 6 o’clock position.

Advertisement — Continue Reading Below

Visually inspect the chamber to make sure it is clear. Now hold the slide back while rotating the takedown lever to the 9 o’clock position. The slide can now move forward off the frame. Remove the recoil spring and its guide, and now the locking block and barrel can be removed from the slide. The barrel and slide can now be cleaned, and there is no need for further disassembly of the gun.

The Bullpup9 doesn’t possess a manual safety, instead relying on its long double-action trigger pull to prevent an inadvertent shot. The hammer looks more like a pickup’s tailgate than a traditional semi-auto hammer, but it does the job and gives the gun a more streamlined appearance when it is at rest. The gun’s trigger mechanism also allows for a second-strike capability.

Trigger Time

The trigger pull on my test gun registered right at 7 pounds and was extremely smooth with some stacking just before let-off. This made the trigger pull very predictable and allowed me to prep the trigger when firing at multiple targets.

Advertisement — Continue Reading Below

For the accuracy portion of my evaluation, I set my targets out at 15 yards and fired five shots for each group. Every group was fired from a seated rest using my DOA Tactical bench as well as a Millett BenchMaster handgun rest for support.

Gordon Bond recommended Winchester’s 115-grain “white box” FMJs for practice, and these rounds performed flawlessly in the Bullpup9. They grouped well and shot to the same point of aim as the higher-velocity defense rounds. I’m happy to report that none of the loads I tried, including some that are not on the recommended list, did not separate while firing. Of course, just about everything I tried possessed a high-performance hollow point with an adequate crimp. The average group size for the five loads I tested measured just under 1.25 inches, proving the Bullpup9 possesses more than adequate accuracy for a subcompact defense handgun.

Advertisement — Continue Reading Below

Despite the very small-diameter recoil spring, the Bullpup9 really doesn’t have much felt recoil. And even though the gun weighs just over a pound, there was nothing harsh or unmanageable about its bite. Part of the credit goes to the beautiful Bond rosewood stocks. While some may criticize them as being too wide, they feel good in my hand and help control the little gun and do not, in my opinion, negatively affect the gun’s concealability.

One Unique Design

There are smaller, lighter, cheaper and even more accurate subcompacts on the market than the Bullpup9, but I’m not sure there are any that are more interesting. Watching the Bullpup9’s journey from concept to production has been intriguing. Without Gordon Bond’s commitment and perseverance, I’m not sure the reverse-feed bullpup would have ever evolved past that of a firearms oddity.

But it has, and it looks as though there is plenty of support to earn its place as a legitimate defensive tool. Gordon Bond tells me his company is tooling up to keep pace with the Bullpup9 orders, and he’ll be adding to the new semi-auto line by offering a Bullpup45 as well as a Bullpup380. Additionally, he’ll soon have a suppressor-ready version of the Bullpup9. You’ll be able to keep track of these exciting new additions by checking in regularly at bondarms.com.

Advertisement — Continue Reading Below

Bond Arms Bullpup9 Review: Specs

- Caliber: 9mm

- Barrel: 3.35 inches

- OA Length: 5.1 inches

- Weight: 17.5 ounces (empty)

- Grip: Rosewood

- Sights: Three-dot

- Action: DAO

- Finish: Matte black, stainless

- Capacity: 7+1

- MSRP: $977

Bond Arms Bullpup9 Review: Performance

| Load | Velocity | Accuracy |

|---|---|---|

| Black Hills 115 JHP | 1,189 | 1.39 |

| Federal 150 Micro HST | 932 | 1.09 |

| Hornady 115 Critical Defense FTX | 1,134 | 1.12 |

| Sig Sauer 147 V-Crown JHP | 1,039 | 1.15 |

| Winchester 115 FMJ | 1,145 | 1.37 |

*Bullet weight measured in grains. Velocity measured in fps by chronograph. Accuracy measured in inches for best five-shot groups at 15 yards.

This Bullpup9 review was originally published in the March/April 2018 issue of “Combat Handguns” To order a copy, visit outdoorgroupstore.com.