For decades, the best option for a repeatable firearms accessory attachment was the Picatinny rail. Picatinny, also known by its military designation, MIL-STD-1913, was originally developed to help attach optics to long guns, but, in the most viral fashion, its uses soon spread to all manners of other accessories, such as flashlights and lasers. Over the years, Picatinny’s modularity made it ubiquitous in the firearms world. With all the free-rail-love going on, the cheese-grater-style aluminum strips started to appear on everything from handguards to buttstocks and everything in between.

- RELATED STORY: 5 Elite KeyMod UpGrades From Bravo Company

As great as a Picatinny rail is, a big drawback to the system is the added weight. Over time, shooting styles changed,

prompting an evolution of the equipment. Rifle handguards got longer, and every inch of additional rail packed on more poundage than an all-Cinnabon diet. At one point, shooters began to question whether they really needed all that Picatinny and looked to shed the excess weight.

We had the opportunity to talk to the man who conceived and developed the lighter-weight alternative that’s taken the firearm world by storm: the KeyMod system. Eric Kincel, KeyMod inventor and research and development director for Bravo Company Manufacturing, gave us a fascinating look into the behind-the-scenes story of KeyMod’s development. He also addressed our suspicions about whether or not this groundbreaking system was based on warehouse racks (you know you’re thinking the same thing!).

Advertisement — Continue Reading Below

The KeyMod To Success

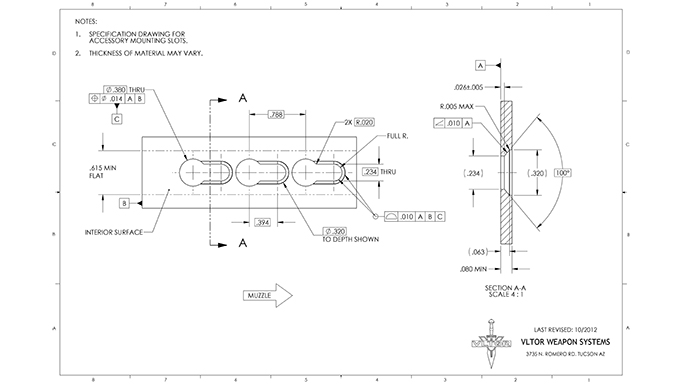

Kincel first had the idea for KeyMod back in 2008, when he was working for Vltor. The idea was discussed among fellow Vltor employees, but for final development, it was Kincel and Vltor’s lead engineer at the time, Jeff O’Brien, who worked to turn it into an industry standard. The concept originally came from the desire to make a rail-type platform lighter, increase ventilation and mainly eliminate the cumbersome Picatinny rail. For years, Kincel wanted to get away from the Picatinny rail’s “o’clock” positions (3, 6, 9 o’clock). He also wanted a system that did not have loose screws and nuts that could be lost, and one that utilized self-contained rail sections and accessories that could easily adapt to an interface system. This concept led to KeyMod, which, he explains, stands for Modular Key Slot.

Semper Fi

Advertisement — Continue Reading Below

The development of KeyMod began during a project Vltor had for the Marine Corps. The Marines came to Vltor requesting an enhanced upper receiver group that allows a standard M16A4 barrel cluster to free-float for maximum accuracy. Never ones to deny a Marine’s request, Kincel and the team served up a specialized Vltor Versatile Interface Structure, a poly-lithic upper receiver assembly called the VIS A5 that eliminated the Picatinny rails at the 3, 6 and 9 o’clock positions. The VIS A5 was a success with the Marines, who wanted to go to the next level of testing. The Marines issued a Request for Purchase (RFP) of the next evolution of the VIS A5, and the team obliged with the VIS A5 KM (KeyMod) upper receiver assembly. The VIS A5 KM was a major achievement over the previous VIS A5 platform because it eliminated the costly mounting points such as pressed-in thread nut inserts and individual screw and rail sections. The elimination of the “press nuts” and the addition of key slot-type holes reduced weight and increased ventilation.

The initial KeyMod concept could have easily been a simple slot with a locking nut like that of a pallet rack you’d find in a warehouse, but Kincel realized that because of its intended use, the system needed to be designed for recoil, counter recoil and repeat zero of all mountable accessories. That’s why his team designed the chamfering and contoured KeyMod nuts; the system would have the geometry to “v-block,” allowing it to re-zero. This is similar to the feature found on the 1913 Picatinny rail.

Enter Noveske

Advertisement — Continue Reading Below

It didn’t take long to go from final concept to first working prototype. The team made up some sample sections of metal to see if the concept worked, which it did. Kincel divulges Noveske’s involvement in the project: “John Noveske actually had a working handguard before we had our chassis built. While we were developing the VIS A5 KM, John called and told me about his new handguard he was developing, the NSR. He showed me models and photos of his prototype, but at the time, he was planning on using the oval backing nut, similar to the oval nuts that Magpul was using on its MOE accessory line.

“John’s idea was great, but seeing that John and I worked tightly together on design concepts, I introduced him to what we were doing for the Marines. John immediately fell in love with the KeyMod system. So, while we developed and built a small number of VIS A5 KMs for the Marines, Noveske developed and produced his NSR rail system first.”

Open Source

Advertisement — Continue Reading Below

Months after the release of Noveske’s NSR, Kincel decided, with the permission of Vltor’s president, Gary Abrams of Abrams Airborne, to release the KeyMod plans free to the world. The KeyMod Tech Data Package (TDP) was made open-source because he realized that the AR-15 industry was coming out with so many different interface rail systems at the time and all that white noise was not advancing the industry.

Kincel adds, “One of the reasons that the American small arms industry has made so many advancements is standardized modularity, like the Picatinny rail. I wanted to make a standard that all the industry designers and engineers were free to use, build products for and move the industry forward, like the MIL-STD-1913 Picatinny rail, which everyone could utilize. Also, by having the industry working together, the new standard would offer a wider accessory range, which is so much better for the end user.”

Universal KeyMod

Advertisement — Continue Reading Below

We asked Kincel how he felt about the industry embracing KeyMod. “I never thought it would take off the way it has,” he commented. “I’m still in shock. I think it was introduced at the right place at the right time, meaning the TDP was released to the industry when it needed it the most. The industry was sick of the cheese-grater 1913 rail, and at the same time, everyone was going to an extreme lightweight rifle design. So instead of developing a system to that design, the industry took the KeyMod TDP and ran with it. It’s nice to see that KeyMod went beyond the U.S civilian market and now it’s being used by specialty DOD units and teams.”

The KeyMod interface seems to be spreading rapidly through weapons manufacturers as well as accessories makers. The system is even appearing overseas on gear made in Europe, as well as for other foreign governments.

No Replacement For Picatinny

Advertisement — Continue Reading Below

Kincel believes that the two interface systems work best together. In his words, “Is KeyMod the end-all design?

I would never say yes to that. I believe it’s what I saw missing at the time I developed it. The 1913 rail is the ideal mounting surface, and in my opinion, the KeyMod interface is the best re-zeroing, lightweight, user-friendly, multi-role interface design that works best with the 1913 rail.”

Kincel adds that KeyMod is not intended to be a straight-out replacement for Picatinny rail. He explains that the 1913 design is ideal for its intended purpose: to be a solid, rigid mounting platform for precision items like optics, thermal-imaging systems, laser-aiming devices and the like. And yes, KeyMod is one of the few interface systems with re-zeroing capabilities. But it was never intended to be a mounting platform for heavyweight, accuracy-critical components. He adds, “The 1913 rail should never leave the 12 o’clock position. It will be around until the AR-15 platform is phased out.”

The Other Guys

At the time Kincel developed KeyMod, he wasn’t a big fan of existing interface designs, stating, “They were either too costly or complex to produce (using Heli-Coils and press-nuts in the chassis), would not allow accessories or rails to repeat zero, or really didn’t have an advantage over the existing 1913 rail. Most accessories for those chassis use individual components (screws, nuts, rail sections), which can be lost or installed incorrectly.”

But he does acknowledge that “Some designs share KeyMod benefits—simplicity, light weight, increased ventilation and solid mounting—but are just less sophisticated designs and lack the secured lockup during recoil and counter recoil and very important repeat-zero features. Some designs are just a square peg in a square hole but don’t take in the factor of recoil, and especially counter recoil. An autoloader like an AR rifle has two directional recoil impulses, rearward recoil and forward counter recoil.” He further describes, “Counter recoil occurs when the bolt carrier group travels forward, feeding the cartridge into the breech, followed by the bolt carrier hitting the barrel extension. This is what destroys optics and loosens accessories. KeyMod was developed specifically to keep all accessories tight with repeat zero, no matter the type of recoil impulse.”

No Kirkland Brand KeyMod

So our suspicions were incorrect: The KeyMod system isn’t repurposed from warehouse racks from Costco. All kidding aside, we all owe a huge debt of gratitude to Eric Kincel and his team for their efforts to create an open-source, simple, lightweight and re-zeroable interface. The KeyMod system has spawned an entirely new generation of handguards and mountable accessories, and revolutionized mounting systems on many weapons platforms worldwide. We’re interested in seeing just how creative firearm makers and accessory designers will get with this system in the future.