Building a smaller .45 ACP semi-auto pistol has been the aspiration of gunmakers since the Colt Commander was introduced in 1950. Since then, 1911s and other semi-autos chambered for the venerable .45 ACP cartridge have been designed and redesigned countless times, in an effort to get as much gun into as small a package as possible. The boundaries for such a project were pretty much established by specialist armsmakers like Para USA, Kimber and Springfield Armory, the latter with its 1911 designs and its polymer-framed XD-S, which became the smallest .45 ACP semi-automatic pocket pistol ever produced. Until now.

Historic Origins

When armsmaker and inventor Arne Boberg developed the innovative XR Series of 9mm semi-autos, he always intended to figure out how to take it one step further and make the same gun in .45 ACP. Like the XR9-S and later XR9-L, the XR45-S took time to engineer. But this is getting way ahead of the story.

Advertisement — Continue Reading Below

The Boberg design is a kind of timeless amalgam of ideas. Some of these ideas date back more than a century, and Arne Boberg has studied and improved upon them, finding the flaws that made some of them eventual failures (like the Gabbett-Fairfax semi-auto) and combined them with one of John M. Browning’s earliest designs, his 1897 patent for the rotating barrel system.

How these two disparate designs from the past work into Boberg’s 21st-century pistol requires an innate understanding of firearms and an ability to interpret, alter and, in the case of the XR Series, reinvent them and change the way they function. Many have tried; history is littered with failed firearms designs. But Boberg’s system may prove to be one of the rare successes.

Reverse-Feed .45

Advertisement — Continue Reading Below

The Boberg design begins with a simple premise: Change the way you load the gun. Since the invention of removable magazines this has been done by inserting the loaded magazine into the grip (unless you want to go back to the Mauser “Broomhandle,” which offered one version with a detachable box magazine) and positioning the first round behind the feeding ramp so that it can be chambered by cycling the gun’s slide. Traditionally, rounds are loaded into a magazine with the bullet nose at a slightly upright angle, to allow smooth chambering.

RELATED: Boberg’s Radical XR45-S Big-Bore Pocket Pistol | Video

Boberg turned this all around. His semi-autos use a reverse-feeding magazine that loads rounds from the back, nose down, and a slide that extracts them from the rear of the magazine. The cartridge is then moved to a lifter that positions it to be gripped by dual extractors in the slide and pushed directly into the rotating barrel breech as the slide closes. This design eliminates the need for a feed ramp; a Boberg barrel is as flush at the breech end as it is at the muzzle. This single change allows a longer barrel length within the same size slide and frame. The difference amounts to anywhere from one half to a full inch without increasing the gun’s overall dimensions. With the XR45-S, the gun’s 3.75-inch barrel takes up the same space as a 3.3-inch barrel in a similarly sized .45 ACP semi-auto subcompact.

Advertisement — Continue Reading Below

The XR45-S also puts down a smaller footprint without creating a firearm that has excessively harsh recoil. This is due to the Boberg’s internal design, which relies on the rotation of the barrel to help reduce recoil.

“Most of today’s 9mm and larger caliber subcompacts have one thing in common,” explained Arne Boberg, “they are chopped-down versions of full-sized guns. What you have are shorter barrels and shorter grips, all of which can compromise accuracy and create guns with harsh recoil.”

Advertisement — Continue Reading Below

With a traditional Browning short-recoil design, the barrel and slide move back in unison during initial recoil until the barrel reaches the point where the shaft on the slide release lever, which either passes through a swivel link on the barrel or acts against a solid camming lug, stops the barrel’s rearward motion and forces it to tilt down and disengage from the slide, allowing it to continue back, extract the spent shell casing and cock the gun. The Boberg operates on an entirely different principle.

“…In weight and balance, the XR45-S feels like a smaller-caliber handgun with a center of balance that falls perfectly into the hand with the little finger tucked under the magazine…”

When the Boberg is fired, the barrel moves back in unison with the slide about 0.125 inches and then begins to rotate 23 degrees counter-clockwise before unlocking from the slide, which then continues its rewards travel. The barrel remains parallel to the slide, rather than tilting down as in traditional short-recoil designs, and thus the Boberg barrel never leaves horizontal alignment. The primary advantage here is the reduction in recoil, a longer locking delay for higher-velocity (+P) ammunition, as well as improved accuracy since the barrel does not have to tilt back up before reengaging the slide.

Beretta takes a similar approach with the PX4 Storm (on a slightly larger scale), but in order for the Boberg design to work it requires more than a rotating barrel. It needs another innovation based in part on another historic design: a reverse-feeding magazine.

Advertisement — Continue Reading Below

When inserted, the magazine in a Boberg sits under the barrel breech, rather than behind it as in other semi-autos. By placing the rounds beneath the barrel breech, the frame and slide can be shortened proportionately. When the Boberg discharges, the next cartridge is drawn from the back of the magazine, brought up to the level of the rotating barrel and inserted straight into the chamber as the slide closes.

In the Boberg, the fresh cartridge is held by the slide just like the Gabbett-Fairfax design, but the top of Fairfax’s gun was open at this point, and the inertia on the cartridge as it was stripped from the magazine often caused it to flip up, fly straight back and out of the gun before it could be chambered. That ultimately spelled the end of the Gabbett-Fairfax. The Boberg design keeps the cartridge held under the cover of the slide, where it is grasped by the dual extractors and carried forward to be chambered. Envision a robotic arm picking up an object from a shelf and then placing it on the shelf above. That’s more or less what is happening inside the Boberg as a round is removed from the magazine and loaded into the chamber.

Advertisement — Continue Reading Below

RELATED: Boberg Arms’ XR45-S Semi-Auto Pistol

In building the Boberg it was also essential to reduce carry weight as well as size. The XR Series models use a lightweight, aircraft-grade aluminum frame with a deep backstrap arch, combined with a stainless steel slide that has eight deeply cut rear serrations. The XR45-S has an overall length of just 5.77 inches, a height of 4.4 inches, a 1.08-inch width and a weight of only 22 ounces. The exterior design features a large, oval triggerguard integral to the frame. The Boberg is a double-action-only (DAO) design with a very smooth trigger pull, a passive firing pin safety and a flat, paddle-shaped hammer. In weight and balance, the XR45-S feels like a smaller-caliber handgun with a center of balance that falls perfectly into the hand with the little finger tucked under the magazine.

Internally, this is a very different gun compared to other semi-autos. It has specific maintenance requirements, including 22 lubrication points during cleaning and a special (supplied and available) moly-based anti-seize lubricant that needs to be applied to the gun’s removable locking block during routine cleaning. It is interesting that with all the minutiae for proper internal lubrication, the Boberg is designed for very easy field stripping with a single, large takedown lever. The disassembly process is straightforward, with only three parts to remove from the slide.

On The Firing Line

Advertisement — Continue Reading Below

While the XR45-S is comparatively narrow for a .45 ACP, your hand really wraps around the grips. The very deep arch of the backstrap allows 1.25 inches of the frame and slide to rest over the web of your hand, so it is a really solid grasp. Average trigger pull on the test sample was 6.25 pounds, measured on a Lyman trigger pull gauge.

“…the Boberg has a taste for Sig Sauer’s 200-grain JHP, which consistently printed five-round groups averaging 1.75 inches…”

The hammer-fired Boberg has a unique flat hammer that doubles as a dustcover at the back of the slide. When the trigger is pulled, the hammer panel comes back just like a traditional hammer would, only it is flat.

Chambering the first round (which is necessary on every reload) is not overly difficult because the Boberg has a remarkably light recoil spring and pencil-lead-thin guide rod, which, rather than being under the barrel, run parallel down the left side of the slide. They are also removed from the rear of the slide when field stripping. The tip of the guide rod (which is pointed) actually protrudes through the front of the frame and extends next to the barrel when the slide recoils. Since the slide does not lock back after the last round is fired, it is wise to count your shots. Additionally, the magazine release takes a solid press and the mag itself has to be withdrawn from the grip frame, so a quick tactical reload is more challenging.

Advertisement — Continue Reading Below

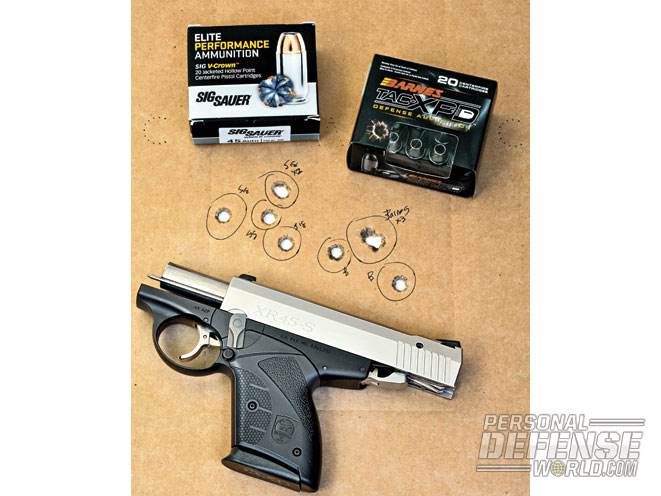

Test ammunition consisted of Federal Premium 230-grain Hydra-Shok JHP, Sig Sauer 200-grain Elite Performance JHP and Barnes TAC-XPD 185-grain +P. Since the XR45-S is designed for +P ammo (and can also fire .45 Super), personal defense ammo was the choice all around. The Barnes 185-grain is specifically designed for a higher velocity and reduced recoil, and it clocked 845 feet per second (fps) with a ProChrono chronograph. Sig Sauer cleared the traps at 858 fps, which was the fastest. The heavy 230-grain Federal Premium flew at 800 fps. Law Enforcement Targets’ IPSC competition silhouettes were set up at a measured distance of 15 yards and all tests were done using a Weaver stance and two-handed hold. The trigger pull felt very smooth with no stacking and a quick reset, making the XR45-S pistol easy to shoot consistently.

If a handgun can show a decided preference for one brand of ammunition over another, the Boberg has a taste for Sig Sauer’s 200-grain JHP, which consistently printed five-round groups averaging 1.75 inches, with two overlapping shots. Barnes 185-grain +P came next, with one failure to feed out of 50 rounds and an impressive 1.75-inch best group, with three overlapping. Also with one failure to feed, Federal Premium had the widest spread, with a best five-shot group of 3.25 inches.

Parting Shots

In terms of handling, the Boberg is fast to shoot but slow to reload. The light trigger pull, noticeably reduced recoil and impressive consistency are counterbalanced by its quirky magazine loading, the slide not locking back after the last round is fired and a higher-than-normal potential for a failure to feed with certain types of ammo. Overall, this is a very impressive handgun to shoot. It is smaller than any other .45 ACP on the market, lightweight, accurate, easy to field strip and, despite its few shortcomings, not a gun likely to disappear into the annals of history.