You’re an infantryman defending against an insurgent assault in Paktika Province, southeast Afghanistan, by the Pakistani border. The enemy is armed with ever-present AK-47s as well as RPGs, but they also are firing a PK machine gun, the large, heavy Kalashnikov design in service since 1961. The PK is a formidable weapon, firing 7.62x54R ammunition, the same round used in World War II’s Mosin-Nagant rifle and more powerful than the 7.62x51mm ammunition in the FN M240, the standard NATO machine gun.

Your rigid body armor is heavy and cumbersome, but it will prevent a PK round from boring a hole in your chest. That’s only half the story, however. The big bullet unleashes a large amount of force even if it bounces off your protective plate. It will knock you off your feet with sledgehammer force, crushing the armor against your body with enough impact to break ribs and shock critical organs.

Fortunately, you’re wearing additional protection, a seemingly magical vest between your armor and your body that protects you from blunt-force trauma even though it defies your understanding. You move forward, cautious but confident, and help to neutralize the opposition. Danger does not come your way this day, but you are ready for it.

Advertisement — Continue Reading Below

Stopping Blunt Force

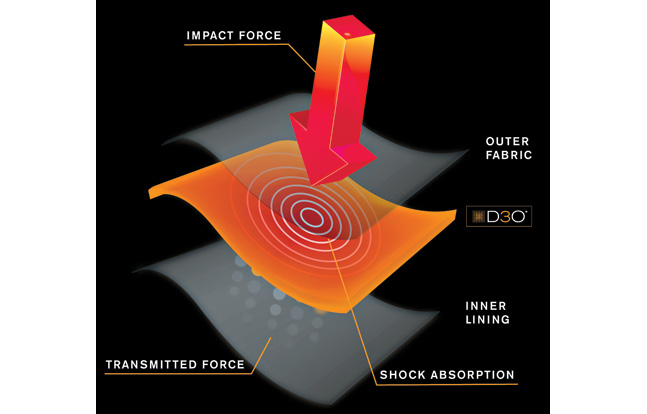

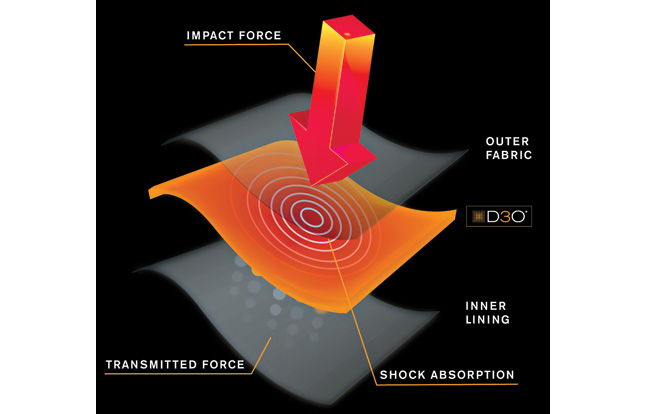

Troops now have unprecedented levels of protection against massive blunt-force impact thanks to innovative developments in polymer science. D3O, a small company of engineers, chemists and designers headquartered an hour outside London, has become a global leader in producing a material with unusual, counterintuitive properties that reacts to sharp blows in proportion to the force exerted and just as quickly returns to its original state.

D3O, founded by a scientist and engineer with a background in chemicals and polymers, produced its first commercial application, protection pads for Alpine skiers, in 2006 and has rapidly expanded since. The company’s products utilize polymer materials. The textbook definition of a polymer is a large, high-mass molecule with many repeated subunits. This structure gives polymers a variety of properties, and D3O is unique.

Advertisement — Continue Reading Below

“D3O is a non-Newtonian, or rate sensitive, polymer material. Its properties change based on the amount of force applied,” explained D30’s Communication Manager, Louise Wilson. “A ball of D3O in its raw state feels solid, but if you leave it on a tabletop, it will eventually melt into a puddle. However, if you hit it, D3O locks together and behaves like a solid, then returns to its flexible state. Our engineers turned D3O into a practical material. It’s soft and flexible, but the harder it’s hit, the quicker the solidifying and shock-absorbing reaction.”

The material is counterintuitive because when something strikes it, the polymer molecules bunch together instead of dissipating, creating a solid, shock-absorbing medium that returns to its original state after impact and reacts comparably after repeated impacts. The harder the force, the quicker the reaction, giving D3O a wide range of protective capabilities for users.

The real key to D3O’s success is integrating polymer with other materials that enable it to stabilize. “By itself, D3O is a very thick liquid, very sticky and messy,” Wilson said. “If we merely fill a knee pad with the raw material, it sinks to the bottom of the bag. Our patents are based on combining it with other materials to create something truly practical.”

Advertisement — Continue Reading Below

Wilson added that D3O will not stop a bullet like Kevlar or other ballistic armor. It is designed to protect against blunt force. However, when worn under body armor, it helps to contain bullet impacts projected through soft or hard armor plates. Even without projectile penetration, a round’s force can cause significant tissue damage similar to a strike from a bat, axe handle or hammer. A sufficiently strong impact can kill, and is likely at the least to break bones or cause disabling hematomas. D3O can mitigate this damage to a considerable extent and, in some instances may, eliminate shock effects.

As noted earlier, the company’s first products were shock-absorbing pads for skiers, and they proved so effective that the Canadian and U.S. Winter Olympic ski teams quickly adopted them. The pads are contoured to protect knees, elbows and other vulnerable areas, and they are lighter in weight and more breathable and flexible, with better protective properties, than competing pads. D3O explored more ways to integrate its unique polymers with other materials to provide optimal energy-locking properties that can be worn to provide protection in environments where heavier blows are likely to occur.

New applications followed for motorcycle riders, and football and baseball players that are effective in a variety of temperature ranges. In addition, the company has focused on military and law enforcement operations as well.

Advertisement — Continue Reading Below

Trusted Security

“We’ve developed a new range of products under the TRUST label,” commented Wilson. “TRUST stands for ‘trauma reduction and unrivaled shock technology.’ We are producing ready-to-wear TRUST knee and elbow pads, boot insoles, helmet pads that exceed the impact standard of 10 fps by 33 percent, and a jacket with pad panels. We’ve already provided gear to the French Gendarmerie for riot protection. U.S. special operations forces are also very interested in our products. We’ve evolved from a company focused on sports protection to military technology systems that can support innovative tactical applications.”

TRUST is the first in-house consumer product line for D3O, manufactured in the company’s factories in the UK, U.S. and Asia. D3O has established partnerships with at least 100 end-product manufacturers that incorporate the company’s materials into sport and military apparel and gear to provide impact protection. The seven-piece helmet liner system offers exceptionally effective deceleration and protection. It attaches directly to combat helmets with a hook and loop system and shapes comfortably to the user’s head. Both external and internal elbow and knee pads are available. Internal pads fit into uniform pad pockets, and external pads are available in regular and extra-long sizes and include a flexible adjustable straps and a hard shell to prevent abrasion. Insoles round out the TRUST line to dissipate high impact from running and jumping in combat boots and help reduce injuries to feet, knees and hips. Insoles utilize D3O Decell material in the heel for cushioning and D3O Aero material for comfort in the forefoot area.

Advertisement — Continue Reading Below

These products, like all of D3O’s developments, focus on performance. Designers utilize CAD/CAM software to ensure every item is optimally fit for its intended purpose and application. Every product completes extensive prototyping and testing, and a product support team is available to help users in the field.

D3O materials cannot be reshaped by melting; do not react to petroleum products; are flame, water, temperature and UV resistant; and stand up to repeated use for up to three years. The company offers several types and grades of material tailored for a range of applications and operational environments, depending on the amount of blunt force encountered.

Athletes, law enforcement officers, military personnel and everyone exposed to possible injury from blunt-force trauma can benefit from the remarkable protective properties of D3O materials, even if they don’t understand how or why these remarkable polymers work as they do. As these materials gain currency, it is likely that the company will create even more products with broader applicability for a variety of functions ranging from hazardous to mundane.

Advertisement — Continue Reading Below