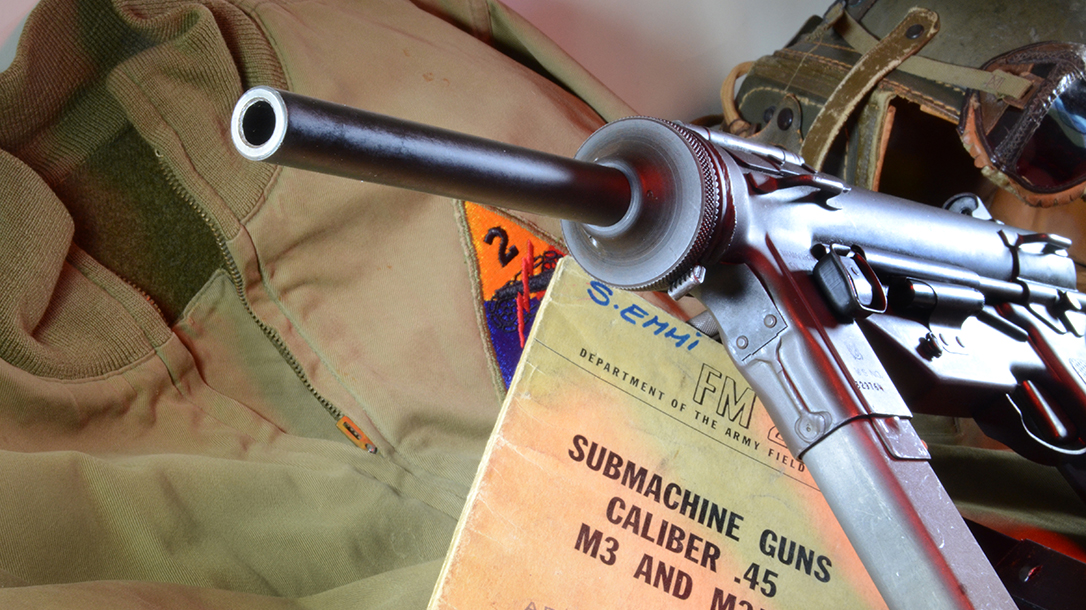

Compared to most U.S. infantry weapons of World War II, the M3 submachine gun is not especially well known. This is even more remarkable given that it is the longest-serving SMG in U.S. military history, having been used from 1942 to 1992.

The M3’s resemblance to the tool used to lubricate automobiles resulted in its nickname, the “Grease Gun.” Many of those who do recognize the M3 may know it more by that title than its official designation. The M3 has been portrayed onscreen a few times, including the film “The Dirty Dozen” and in HBO’s “Band of Brothers.”

Advertisement — Continue Reading Below

A New Direction

Development of the M3 began in 1941 when the U.S. Army Ordnance Board became interested in an inexpensive, mass-produced submachine gun akin to the British Sten Gun. This in itself was quite a turnaround as, unlike many European armies, the U.S. Army had never really been especially enamored with SMGs. At the time, the U.S. submachine gun was the Thompson, which had been adopted to a large extent because it was available and already in production at the start of the war.

The Thompson was effective but heavy and expensive. Based on a list of requirements submitted by the Army, specs were developed for an all-metal weapon, chambered for the .45 ACP cartridge, capable of either semi- or full-auto fire, having a low cyclic rate and capable of being inexpensively mass produced. The original specifications had offered .30 Carbine as an alternative to .45 ACP, but the pistol caliber was chosen. To save costs, the capability of firing on semi-auto was eliminated, so the M3 could only be fired on full-auto.

Working with engineers from the Inland Manufacturing Division of General Motors, the Ordnance Department developed what was designated the T-15. Specifications of October 8, 1942, included a stipulation that the T-15 could be easily altered to fire the 9mm round, thus allowing captured ammo to be used and M3s to be supplied to allies or Resistance fighters.Another stipulation was that the capability of firing semi-auto be eliminated to make production easier and less expensive. Because the M3 had such a low cyclic rate, it would be much easier to fire one or two shots through trigger control.

Advertisement — Continue Reading Below

T-20

The version incorporating these changes was designated the T-20. Five prototypes of the T-20, along with five 9mm conversion units, were built by General Motors for testing. In accuracy testing on a 6-by-6-foot target at 50 yards, the T-20 scored 97 hits out of 100. For comparison, a Thompson SMG used as a control scored 93. During a reliability test of 5,000 brass-cased .45 ACP rounds, there were only two failures to feed, both attributed to defective magazine followers. An additional test of 500 rounds of steel-cased .45 ACP had three failures to eject and one to feed. Additional reliability tests included those in mud and dust. The T-20 proved more reliable than other SMGs that were tested. Tests of the T-20 were also carried out by the U.S. Army Airborne Command, the Amphibious Warfare Board, the U.S. Army Infantry Board and the U.S. Armored Forces Board. All recommended its adoption.

An Ordnance Committee memo from December 23, 1942, recommended its adoption as “US Submachine Gun, Caliber .45, M3.” Its production was approved in January 1943, and production began in May 1943. An initial contract for 300,000 Grease Guns was awarded to the Guide Lamp Division of General Motors because of this division’s expertise in the use of stampings in production.

Devil’s In The Details

Other than the barrel, the bolt and a few other smaller parts, the M3 was produced entirely of stampings at a cost of around $18.36 per unit, plus $2.58 for the bolt assembly, which was subcontracted. The cost of the M3 was about half that of the M1A1 Thompson, and the production time required was about half as well. Many of the production shortcuts used by the British in making the Sten Gun were used in making the M3. For example, as with the Sten, M3 barrels were cold swaged. By the end of 1943, Guide Lamp had produced 85,130 M3s, with production in 1944 rising to 343,372. A final 162,723 M3s were produced in 1945.

Advertisement — Continue Reading Below

Prodlems arose in 1944 with issued M3s, including cocking handle assembly failures and fragile rear sights, among others. These problems were fixed in later M3 production.

In May 1944, the Tank Destroyer Board requested a fix to magazines being inadvertently released, resulting in a guard being added around the magazine release. To fix tankers damaging the bolt face and chamber by using the stock as a cleaning rod, a stop plate was added between the stock rods.

Simplification

In April 1944, the Ordnance Department and Guide Lamp began work on simplifying the M3 even more. Not all suggested changes were implemented, but among those that were was the elimination of the cocking handle/crank. Instead, the bolt was designed to incorporate a recess, which allowed the finger to be used to pull back and cock the bolt. Among other changes was the incorporation of a loading tool into the buttstock, incorporating a longer ejection port and ejection port cover/safety flap, and strengthening the rear sight. On February 22, 1945, the new design was adopted as the “Submachine Gun, Caliber .45, M3A1.” The M3A1 was slightly lighter than the M3 by a couple of ounces. Before the end of the war, only 15,469 M3A1’s had been produced.

Advertisement — Continue Reading Below

Called To Duty

The ejection port cover/safety flap is one of the more interesting cost-cutting features of the M3/M3A1. Rather than using a conventional selector or safety, the M3’s safety consists of a stud on a hinged ejection port cover. When the bolt is forward, the cover may be closed over the bolt, with the stud engaging a recess in the bolt. This prevents the bolt from being jarred rearward, thus cocking the weapon on a loaded magazine. When the bolt is to the rear, the stud engages a notch atop the bolt, preventing the bolt from going forward. Since the M3/M3A1 fires from an open bolt, securing the bolt in position is very important for safety.

As troops got used to the M3, they found it easy to carry with good stopping power. They also grew to appreciate the low cyclic rate, as it allowed greater control. Although it had initially been issued to paratroopers and Rangers on a limited evaluation basis, it did achieve wider use among members of the 17th Airborne Division during Operation Varsity. Tank crewmen and armored infantrymen were also among the early troops to receive the M3. MPs found the M3 a very useful weapon for guarding installations or controlling prisoners. Although intended as a replacement for the Thompson SMG, both continued to be used until the end of World War II, at which point most Thompsons were pulled from service.

Suppressed Variant

A suppressed version of the M3 had been developed for the Office of Strategic Services (OSS). A barrel with an integral suppressor could be easily installed on the M3 by screwing off the standard barrel and screwing on the suppressed one. Since the .45 ACP round is subsonic, standard ammunition could be used, and the heavy 230-grain bullet retained substantial stopping power even when fired from a suppressed weapon. A total of 1,000 suppressed barrels were produced for the OSS contract. Suppressed M3s are notably heavier by more than a 1.5 pounds and are longer than the standard model M3.

Advertisement — Continue Reading Below

During the Korean War, the principal U.S. SMG was the M3A1. Due to the cold weather, care had to be taken not to over-lubricate the M3A1, and troops found that cocking the bolt with their fingers was difficult.

Modern Combat

In 1953, Ithaca Gun Company was given a contract to manufacture over 90,000 new M3 bolts to replace those that had become too worn for continued use. Later in the 1950s, Ithaca was given a contract for 70,000 new M3A1 SMGs to fill estimated future needs. Production took place during 1955 to 1956, but only 33,227 Ithaca M3A1s were produced before the contract was cancelled. This additional production allowed the Thompson to be taken out of service in March 1957.

During the Vietnam War, the M3/M3A1 saw use with U.S. Special Forces, Vietnamese forces and Marine Recons among others. When Delta Force was formed in late 1977, it used the M3A1. Suppressed M3A1s also went along on the Iranian hostage-rescue mission.

Advertisement — Continue Reading Below

After Vietnam, U.S. armored crews were still issued the M3 to carry in their tanks, and tankers in Europe facing the threat of a Warsaw Pact attack had M3s. Armored vehicles in the first Gulf War also carried M3s.

Range Report

I have fired the M3, M3A1 and suppressed versions. As with most skeleton stocks, that on the M3 is not especially comfortable, but it is better than some, such as the AK underfolder. The stock design is such that it channels recoil straight back, which helps to control the SMG during full-auto fire. I like the low cyclic rate as it allows good accuracy in bursts without undue climb. It also allows me to fire single shots through trigger control fairly easily and two-shot bursts easily.

Advertisement — Continue Reading Below

When firing, I place my support hand against the magazine well and pull the weapon back against my shoulder. The crank handle on the M3 allows better leverage for cocking the weapon but sticks out; using the finger on the M3A1 requires more effort but there is no protruding crank to catch on gear.

The M3’s ejection port cover is what it is. It has to be flipped up before firing with the support hand and flipped down to render the weapon safe. I find the location of the magazine-release button allows me to hit the release with my support-side thumb while pulling the magazine free. The fixed sights are adequate out to 50 yards.

Final Thoughts

For a World War II Class III collector, the M3 is extremely interesting. It is also a very usable working SMG, especially since it packs the power of the .45 ACP. It was issued to paratroopers in WWII, and I wonder whether I would have traded in my M1A1 for the M3. If I had a choice, I probably would not have. The M1A1 offered longer range and better accuracy. However, for clearing cities during the drive on Germany, the close-range power of the M3’s .45 ACP round might have convinced me.

Advertisement — Continue Reading Below

All in all, I would say the M3/M3A1 Grease Gun has definitely proven its worth over the years!

U.S. M3 Submachine Gun Specs

| Caliber: .45 ACP |

| Barrel: 8 inches |

| OA Length: 22.8-29.8 inches |

| Weight: 8.15 pounds (empty) |

| Stock: Collapsible |

| Sights: Front post, fixed rear peep |

| Action: Full-auto, blowback |

| Finish: Parkerized |

| Capacity: 30+1 |

This article was originally published in the 2016 issue of “Military Surplus.” To grab the latest copy of this magazine, visit outdoorgroupstore.com.