The first time I’d seen the buck was through a spotting scope. He was 360 yards away and a year younger. On opening day of deer rifle season, I decided to sit in a ladder stand tucked into a cedar grove that gave me view of a 15-acre field, which had been a dairy pasture a half-century before and was now a mix of briers and broom sedge. My choice of weapon that morning was a modern sporting rifle.

On the Hunt With the Anderson Manufacturing AM-10 Hunter

I had high expectations, having watched several mature bucks travel the field the previous summer. Arriving at the stand just as the eastern sky began to glow, I hoisted up my pack and rifle and got situated. Fifteen minutes after legal shooting light, I kept a close eye on the corner of the field to the southwest, knowing that was a common entry trail for the field. When I scanned back to the north along my entry path into the field, I was surprised to see a big buck skirting along the edge of the woods.

Advertisement — Continue Reading Below

I raised my binoculars and immediately dropped them again to move the rifle into position. As the heavy-beamed buck stopped just short of the tractor road that bisected the field, I settled the Bushnell Engage’s crosshairs behind the buck’s shoulder while he turned his head toward me. The width of his rack registered in my mind as I started applying pressure to the trigger.

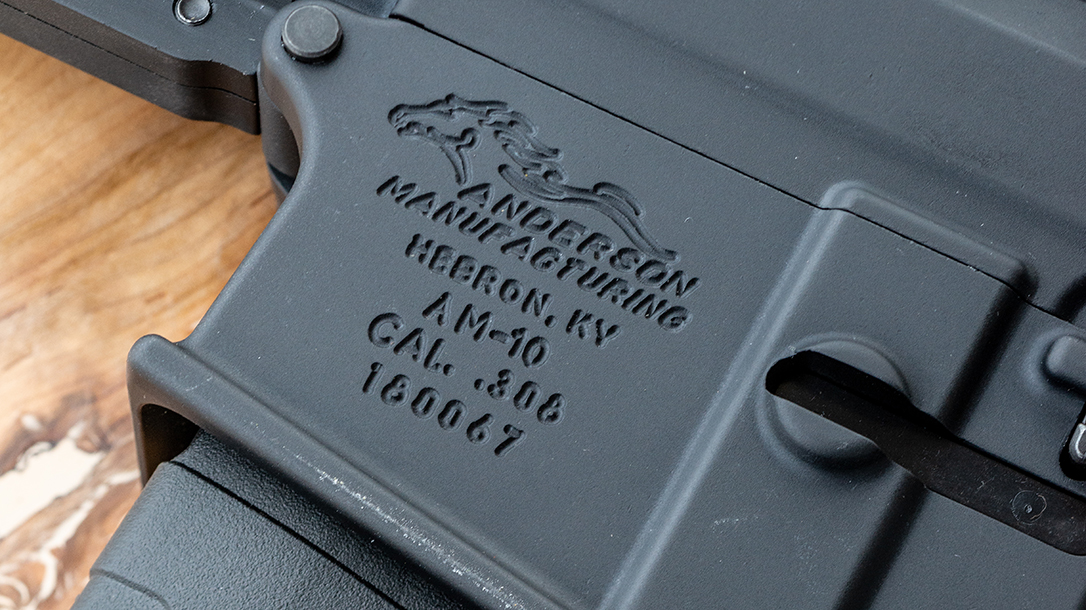

Not only was I familiar with the buck that stepped into view 225 yards north of my stand, but I was fully prepared with newest version of Anderson Manufacturing’s AM-10 in .308 Winchester/7.62mm NATO. Two years earlier, I had quite a bit of trigger time with the first generation of the rifle now in my hands.

Reducing Friction

Six weeks prior to that hunt, the Montana morning was clear and crisp as a couple dozen magazine editors and writers gathered in a high plains pasture to hammer some steel with new rifles and pistols in the first days of October. One of the rifles that I tested was the Anderson Manufacturing AM-10 Hunter.

Advertisement — Continue Reading Below

Something that sets Anderson’s rifles apart is that they are capable of hitting extremely high round counts without cleaning. Most ARs will keep running if you keep hosing them down with gun oil. However, this company’s patented process ignores conventional wisdom by recommending that oil never touch its rifles.

Borrowing some new metallurgy technology used by top NASCAR racing teams to reduce friction in engines and drivetrains, Anderson Manufacturing applied the same science to AR-15s as the company entered a crowded gun market in late 2009. By applying the treatment to AR uppers, lowers, barrels and other parts, the Hebron, Kentucky, tool and die company was able to reduce friction on moving parts by 85 percent—without lubricants. Needing a name for the metal treatment, the engineers didn’t overthink the issue and named it simply RF85, for “Reduced Friction 85 percent.”

Going into the Gun Business

Thanks to the Great Recession wreaking havoc on American industry a decade ago, Anderson Manufacturing was forced to seek alternatives to its devastated automotive and aerospace customers just to stay in business. Anderson has been in business for more nearly 50 years as a contract machine shop. Since the sales of firearms—and ARs in particular—were skyrocketing in the wake of Obama’s election, Anderson’s Vice President of Sales Tom Steffner suggested to owner Carl Anderson that they get into the firearms business. It was a simple step to apply their knowledge of metal fabricating and treatment processes to building AR parts.

Advertisement — Continue Reading Below

“We entered the gun market in late 2009, making OEM parts for other manufacturers,” Steffner said, “but after the SHOT Show, we decided to get into building the guns ourselves in January 2010.” Nine years later, Anderson Manufacturing has risen to the top of the firearms industry. In 2016, only Remington and Ruger produced more rifles than Anderson Manufacturing’s 453,763, according to the BATFE’s 2018 reports on the firearms industry.

“We can tell a difference in our guns,” Steffner added. “We’ve got something nobody else has with the RF85 process. We just jumped in with both feet and started building guns. The RF85 treatment isn’t marketing hype. This is something that has been scientifically proven by the Oak Ridge National Laboratory.”

Anderson’s RF85

RF85 isn’t a surface coating, but instead adds a calcium component throughout the metal. In a laboratory setting, a piece of the treated metal beneath the surface layer was bombarded with electrons to emit gases yielding the metal’s component materials, and the lubricating calcium-like material was detected. In other words, the RF85 treatment won’t wear off with use. The same treatment applied to metal reduces heat from friction, too. Medical saw blades—used for cutting off the bottom of the femur in knee replacement surgery—stayed more than 100 degrees cooler than non-treated blades, thereby reducing bone tissue damage by half.

Advertisement — Continue Reading Below

The Oak Ridge National Laboratory tested Anderson’s rifles and found the reduction of friction on all steel surfaces reduced by 85 percent. According to Oak Ridge, an RF85-treated weapon cycles 23-percent faster and more reliably than a non-RF85-treated weapon with traditional wet lubricant. The RF85 guns operate at cooler temperatures and experience significantly less wear, all without traditional wet lubricant. RF85-treated rifles also don’t experience failures due to excessive dirt and carbon fouling in the action, either. As the Oak Ridge testing report put it, “There are several advantages associated with friction reduction in general, two of those being heat reduction and increased component life.”

The RF85 treatment sets Anderson’s rifles apart from other ARs. It allows them to operate efficiently without a traditional “wet” lubricant. The same magic is what makes these rifles easier to clean, too. I’ve run more than 3,000 rounds through other Anderson rifles. The cleanup process required warm soapy water and a bristle brush to remove the last bits of carbon buildup. That’s it. Afterwards, I simply laid the gun outside in the sun and let solar energy dry the metal parts.

Test Model

The AM-10 Hunter that I tested in Montana and used for the hunt I mentioned earlier sports a 16-inch barrel and an 11.5-inch handguard. The completely redesigned receivers feature forged, hardcoat anodized 7075-T6 aluminum. The rifle also sports a full-length Picatinny rail on top for sights and optics. The rest of the furniture includes a Molding Solutions T17 buttstock and a Magpul MOE pistol grip.

Advertisement — Continue Reading Below

But there’s more to the design. While some manufacturers are suffering from the slowdown in the AR sales market, Anderson is kicking its innovation into high gear. The company has designed several new patented AR parts that can be found in the AM-10 Hunter, including the new HT Gas Block System, which eliminates seized or stripped setscrews and the deformation common in gas block installation. It accomplishes this with simple, exact alignment of the gas port, block and tube. Two precisely machined orientations on the top and bottom provide alignment and concentric sealing of the gas block on the barrel.

Another Anderson upgrade is the Quad Lok (QL) handguard system. It provides precise, repeatable assembly with easy fastener access. The base coupling and handguard system orient with four Quad Lok alignment points, which eliminates slotted clamp seizing.

The AM-10 Hunter with the RF85 treatment on the barrel and action has an MSRP of $1,385. Or, you can order it without the special treatment for $280 less.

Advertisement — Continue Reading Below

In The Field

To get a fair basis of comparison for the AM-10 with other rifles of this type, I opted for a standard function and accuracy regimen. Initially, I installed a 3-12x42mm Bushnell Engage scope and sighted it 1.5 inches high at 100 yards. It took a total of five rounds to get a rough zero, so I sent the rest of the 20-round magazine loaded with Hornady’s 150-grain American Whitetail ammo downrange to do some plinking on steel targets out to 200 yards. The barrel got a good scrubbing with a Hoppe’s BoreSnake—one pass for every round fired. One more round went downrange to clear out any cleaning solvent, and another to re-confirm my zero. I set the gun aside for a few days in anticipation of the deer season opener.

With the scope’s crosshairs firmly planted, the shot broke, and I heard the bullet impact. The buck mule-kicked, charged across the field and disappeared into a tangle of briers and cedar scrub. I retrieved my Thermos and enjoyed a cup of coffee.

Success Afield

Confident in the shot, I didn’t even take up the blood trail. Instead, I walked the half-mile back to the house to get my son’s Labrador retriever, Kate, to join me for the recovery. We parked the four-wheeler where the buck had stood at the shot. It took Kate only a few seconds to sort things out. Nose to the ground, she trotted across the field and disappeared.

Ducking branches and stomping down some wicked briers, it didn’t take me very long to find her sitting next to the wide nine-pointer. Kneeling down and offering Kate some words of encouragement for a job well done, I inspected the buck’s 23.5-inch-wide rack. The familiar shape told me that I knew this buck from several trail camera photos and personal observation a year prior. A short prayer—thanks for a successful hunt, and regrets that Kate’s master wasn’t there to share the recovery with us—and we set about our chores.

Earning Its Name

Over the next few days, I swapped the AM-10’s optic for a Bushnell 3.5-21x50mm Elite Tactical HDMR II to finish the rifle’s accuracy evaluation. Lining up the Oehler 35P chronograph with my 100-meter berm, I collected velocity data and fired five-shot groups with five different factory loads. See the table below for the best groups fired with each load, including average velocities from 10-shot strings.

All in all, the rifle impressed me. The Anderson Manufacturing AM-10 Hunter lives up to its name. It’s a dependable, accurate rifle that packs plenty of punch.

For more information, visit andersonmanufacturing.com.

Anderson Manufacturing AM-10 Hunter Specs

- Caliber: 7.62mm NATO

- Barrel: 16 inches

- Overall Length: 35.88 inches

- Overall Weight: 8.4 pounds (empty)

- Stock: Molding Solutions T17

- Sights: None

- Action: Direct impingement semi-auto

- Finish: Matte black

- Overall Capacity: 20+1

- MSRP: $1,385

Anderson Manufacturing AM-10 Hunter Performance

Load Velocity Accuracy

- Federal 168 Gold Medal SMK 2,386 0.88

- Federal 175 Gold Medal SMK 2,368 0.70

- Hornady 150 American Whitetail 2,658 1.34

- Hornady 168 A-MAX 2,525 0.96

- Winchester 168 Match 2,446 1.18

Bullet weight measured in grains; velocity in fps by chronograph; and accuracy in inches. Best five-shot groups at 100 yards.

This article is from the October-November 2019 issue of Tactical Life magazine. Grab your copy at OutdoorGroupStore.com. For digital editions, visit Amazon.