Lewis Machine & Tool (LMT) is a top-tier manufacturer that you don’t hear too much about in the commercial marketplace. That’s unfortunate, as the company’s build quality and reliability are top-notch.

- RELATED STORY: 3 Elite Combat AR Rifles From Lewis Machine & Tool

LMT designs and fabricates complete weapon systems, including grenade launchers and Monolithic Rail Platform (MRP) series rifles. Karl Lewis founded LMT in 1980 to provide the U.S. military, law enforcement and government agencies with high-quality weapons systems and components. As a military contractor, all of the company’s rifles are manufactured to military specifications. Fortunately for us, LMT also offers identical military-grade firearms to the private sector, directly and through its dealer network. In fact, Lewis Machine & Tool’s production is split about 50/50 between military/law enforcement and civilian sales.

LMT manufactures all of its major components in-house. The roll pins, springs, receiver endplates and firing pins are the only purchased parts. The big advantage of LMT’s in-house capabilities is that it eliminates tolerance issues that are common when sourcing parts from numerous manufacturers. The company is also able to closely monitor and adjust its supplies and inventory as needed. This is a big advantage when the private market accelerates wildly and part supplies dwindle.

Advertisement — Continue Reading Below

Mod Squad

The LM308MWS was originally developed for a UK Ministry of Defence request. It was designed to operate reliably in all extreme weather conditions and was tested successfully from -40 to 158 degrees Fahrenheit. Within the UK military, this rifle is designated the L129A1. The standard version of the rifle comes equipped with a stainless steel barrel and an adjustable SOPMOD stock. For this article, I tested LMT’s newest version, the LM8MWS, that came with a 16-inch, lightweight-profile, stainless steel barrel and a DMR buttstock. The upper receiver is a smooth-sided design without a forward assist—also a military request. A Flat Dark Earth Cerakote finish has been applied over the hardcoat anodized parts. This process yields a stronger, longer- lasting finish.

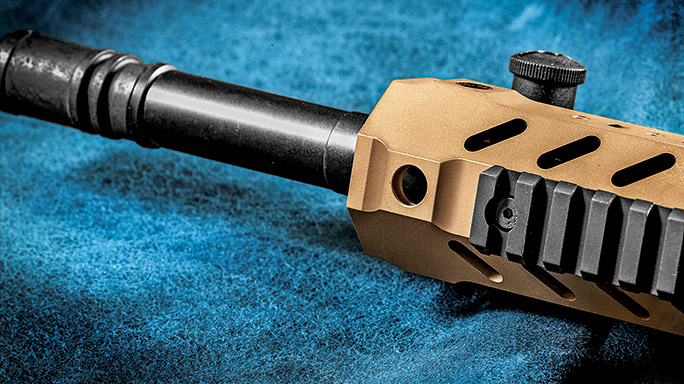

The LM8MWS’ most distinctive features are its MRP upper, quick-change barrel system, ambidextrous safety selector and ambidextrous magazine release. The MRP is a one-piece, lightweight upper receiver with an integral forend. An uninterrupted Picat-inny rail runs the full length of the upper, and users can attach accessory rails along the sides and bottom. The segments attach with one, two or three bolts depending on their length. The absence of full-length side and bottom rails reduces the circumference of the forend, making it easier to grasp. This is especially valuable given the wide girth of typical .308/7.62mm NATO forends. Additionally, since the gripping area of the forearm is smooth, there are no sharp rail edges to abrade your hands.

Advertisement — Continue Reading Below

Combining the forend and upper receiver into a single monolithic upper serves to greatly increase the rifle’s strength and durability, and thereby its reliability—there’s no separate rail system to twist or loosen. Because there is no break between the receiver and rail system, optics can be placed anywhere along the top rail.

Swapping Barrels

Another innovative feature is the quick-change barrel system. Barrels can be changed by loosening just two bolts on the right side of the forend, just forward of the magazine well. The front bolt needs to be removed, but the rear bolt only needs to be loosened three rotations. And, since the LM8MWS’ barrels come with pre-mounted gas blocks and gas tubes, switching out barrel assemblies is quick and easy. Accuracy is all about consistency, so LMT includes a calibrated, 140-inch-pound torque wrench to ensure the barrel’s bolts are torqued perfectly every time. The system works as advertised. It took me half a minute to remove and reinstall a barrel assembly.

Advertisement — Continue Reading Below

All of LMT’s barrels are cryogenically treated to increase their accuracy and longevity, and to make cleaning easier. The LM8MWS is available with numerous barrel options, including 13-inch, chrome-lined barrels with light and heavy profiles; 16-inch, chrome-lined or stainless barrels with light and heavy profiles; and 18- and 20-inch, stainless barrels with light and heavy profiles. My test rifle came with a 16-inch, chrome-lined, .308 Winchester/7.62mm NATO barrel, but there are several other calibers available, including 6.5 Creedmoor, 7mm-08 Remington, .243 Winchester, .260 Remington and .338 Federal.

LMT’s stainless .308 barrels have a 1-in-11.25-inch twist rate while the chrome-lined versions have a 1-in-10-inch twist. Stainless barrels are more accurate than their chrome-lined brethren, but they don’t last as long. According to LMT, stainless barrels will last between 10,000 and 20,000 rounds, while the life expectancy for its chrome-lined barrels is between 20,000 and 40,000 rounds.

The bolt and bolt carrier group have a proprietary coating to reduce friction, increase carrier speed and ease cleaning. The LM8MWS also features an enhanced bolt carrier group with a dual ejector and a lobster-tail-like extraction claw.

Advertisement — Continue Reading Below

Lower Specs

As mentioned, the LM8MWS has both an ambidextrous selector and ambidextrous magazine release. This makes it easy for both right- and left-handed shooters to use the rifle and work around cover.

The trigger is two-stage design manufactured my LMT. Factory specifications call for 2 pounds on the first stage and 4.5 to 6 pounds on the second. The heavy pull weight is a mil-spec requirement in order to pass drop tests. My test rifle’s trigger pull weight measured 6.5 pounds on average. In other words, this is a combat trigger, not a precision trigger. It is designed to be highly durable to withstand harsh battlefield use. Of course, you can always install a new aftermarket trigger if you want a lighter pull.

Advertisement — Continue Reading Below

The LM8MWS includes LMT’s heavy-duty front and rear sights. Their non-folding design is extremely durable—there’s no need to worry about damage if you catch them on a doorframe or other object.

QD sling attachment points abound on the LM8MWS. There are two on the buttstock, one just in front of the magazine well on the left side of the receiver, and three at the front of the handguard. Regardless of how you prefer to mount your sling, the numerous locations offer a lot of flexibility for every shooter.

The DMR buttstock that came equipped on my test rifle features a rubber buttpad and is adjustable for both length of pull and cheek height. The stock’s adjustments make it easy for shooters of various statures to fit behind the rifle and use different optics. A monopod can also be added beneath the stock for long-range precision shooting. As mentioned, the standard version of the rifle includes a SOPMOD adjustable buttstock.

Advertisement — Continue Reading Below

Range Wringout

With the interchangeable barrel system being a major feature of the LM8MWS, I wanted to see if it maintained its accuracy after swapping barrels. I started the live-fire testing by zeroing the rifle in at 100 yards. I then let the gun cool and removed the barrel. The next range trip I reinstalled the barrel, fired the same number of rounds to heat the barrel up, and rechecked my zero. The shots were spot on.

As a reliability test, I ran six types of ammunition that I had on hand ranging from surplus to match-grade fodder. All fed perfectly. Being a .308/7.62mm, the LM8MWS’ recoil is stout but easily manageable due to its heft and compensator.

Advertisement — Continue Reading Below

For accuracy testing, I mounted a Lucid 6-24x50mm L5 scope. I fired five-shot groups from prone using a bipod. The Federal Premium 168-grain Gold Medal Match ammo produced the best groups, and I had numerous groups measuring between 0.5 and 0.63 inches. This would be outstanding for a precision bolt gun with factory ammunition, never mind a semi-automatic with a combat trigger!

Also fed through the LM8MWS was Winchester’s 168-grain Match hollow-point boat-tail (HPBT) ammo which received groups ranging from 0.63 to 0.75 inches. Similar results were obtained when shooting Black Hills’ 168-grain HPBT rounds.

It hard to say what my favorite feature is, but I am going to go with the LM8MWS’ monolithic upper. I am big fan because the added strength and durability certainly increase the rifle’s reliability.

Advertisement — Continue Reading Below

- RELATED STORY: Gun Test: Lewis Machine & Tool’s CQBODGB Rifle

The LM8MWS’s size and high-performance .308/7.62mm chambering allows it to be used for personal and home defense, sport, precision shooting and hunting. Highly accurate, reliable and robust, Lewis Machine & Tool’s LM8MWS has just become one of my favorite rifles.

For more on the LM8MWS information, visit lmtdefense.com or call 309-787-7151.