If you live in a restrictive state, you understand the difficulties they present in firearm purchases. It gets even tougher when you want to build a firearm with any kind of modularity. This is where the Sig Sauer Custom Shop and its P320 FCU (Fire Control Unit) really help.

The Sig Sauer P320 FCU to the Rescue

If you’ve ever doubted the intelligence of the founding fathers, you can be reassured by their choice to use the word “arms” and the phrase “shall not be infringed” when writing the Second Amendment.

They kept the noun vague to encompass as many items as possible. Specifically, because most have experienced some sort of firearms development in their lives. At the same time, they used a verb that is extraordinarily tight for arguably the same reason.

Advertisement — Continue Reading Below

Infringement encompasses every limiting factor imaginable, no matter how slight. For instance, if I’m walking down the hall and you stand in front of me, you infringe upon my travel. The Second Amendment is simple enough to illustrate with crayons, yet our installed officials seem to struggle.

Firearms permitting is a glaring form of infringement through its unrealistic requirements and outlandish fees. Sure, I could turn a blind eye, shell out the cash, and jump through the hoops. But it just doesn’t stop there.

Such is my story of trying to get a Sig 320 FCU through a New York State Pistol Bureau.

Advertisement — Continue Reading Below

What is the Sig FCU?

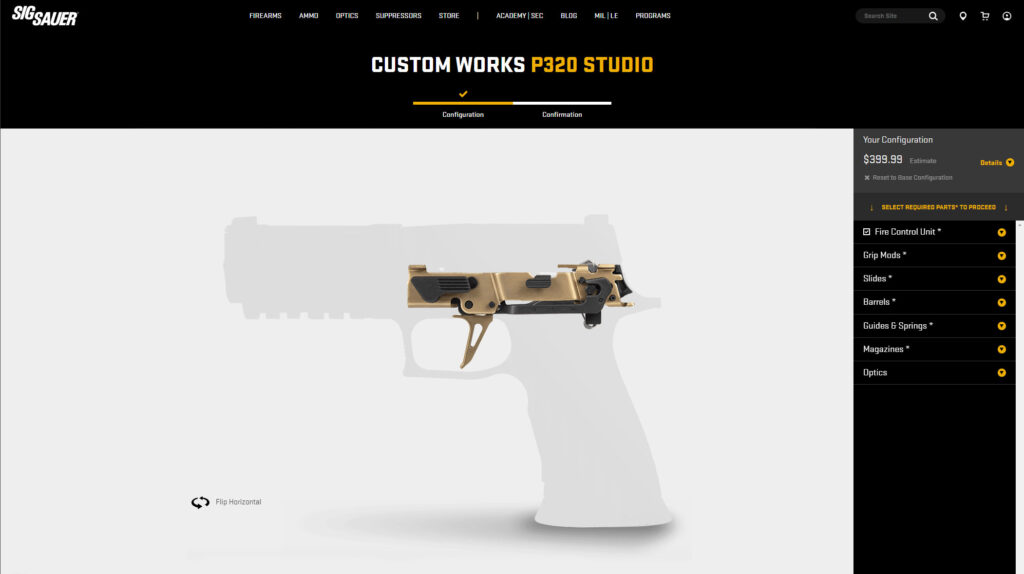

The Sig FCU is a drop-in trigger module that bears a serial number and is classified by the ATF as a frame or receiver. This allows gun owners the versatility to pick the frame size, caliber, and barrel length. Once assembled, simply drop in the FCU for a complete firearm of your choosing.

In New York, pistols must be registered, and the entry must include caliber and barrel length. Uh-oh, now what? To further complicate matters, some jurisdictions came down on their gun shops for manufacturing without a license simply by slipping this FCU into a grip module and adding a slide and barrel.

Advertisement — Continue Reading Below

Naturally, they beat this bogus charge. However, some are still leery and don’t want to be bothered transferring this common system. To help get around this disaster, I ordered all of the parts for a Sig 320 MAX to the gun store. I then brought them, with a photo of the FCU, down to the pistol bureau to plead my case.

After cornering the commanding officer with logic (not to mention the penal code), he eventually threw the grip in my face and said, “Bring it back when it’s a full gun!”

Workaround

If you have a story like mine or you just aren’t a hands-on type of person, the Sig Custom Works Concierge Service will likely be of interest. Customizable platforms are tons of fun. However, a custom-building service is always going to be the easiest way to get a gun that’s built for you.

Advertisement — Continue Reading Below

This web-based program can be utilized 24/7. And it offers the entire complement of Sig parts to build the P320 of your dreams.

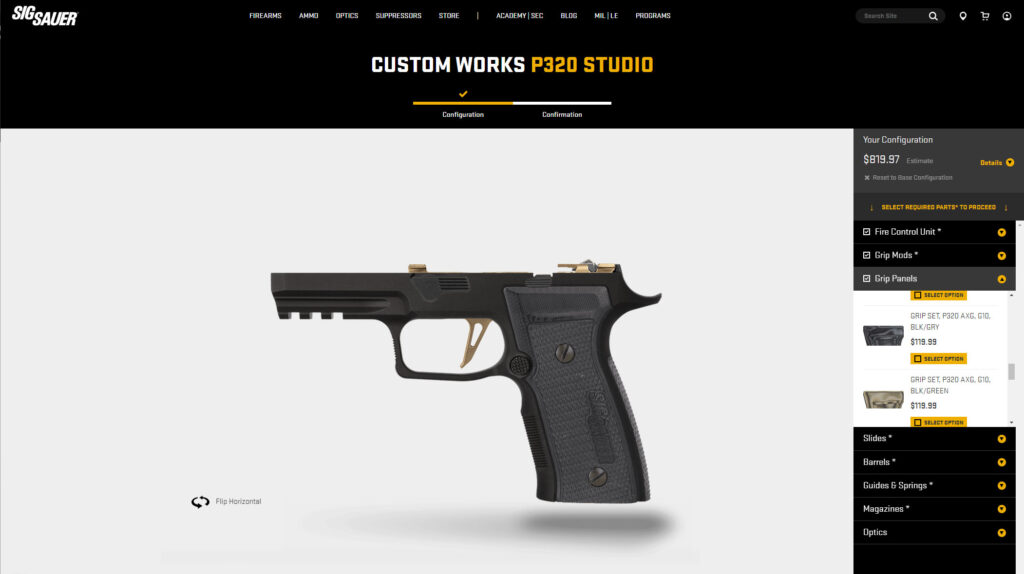

The process begins by making an account and then going through each category to build your gun. The first choice to make is the grip module, in which there are several dozen choices. They span three colors and just about any size you could imagine.

Advertisement — Continue Reading Below

If you choose a module that can accept grip panels, picking out a pair will be the next step. Sig offers choices of polymer, walnut, or G10 for your material. These come in various colors to match or offset the grip mod that they will be attached.

Next, we have to choose a slide. Options range from fully grey man to offerings that rival the best race guns in flair and function.

Finalizing your P320

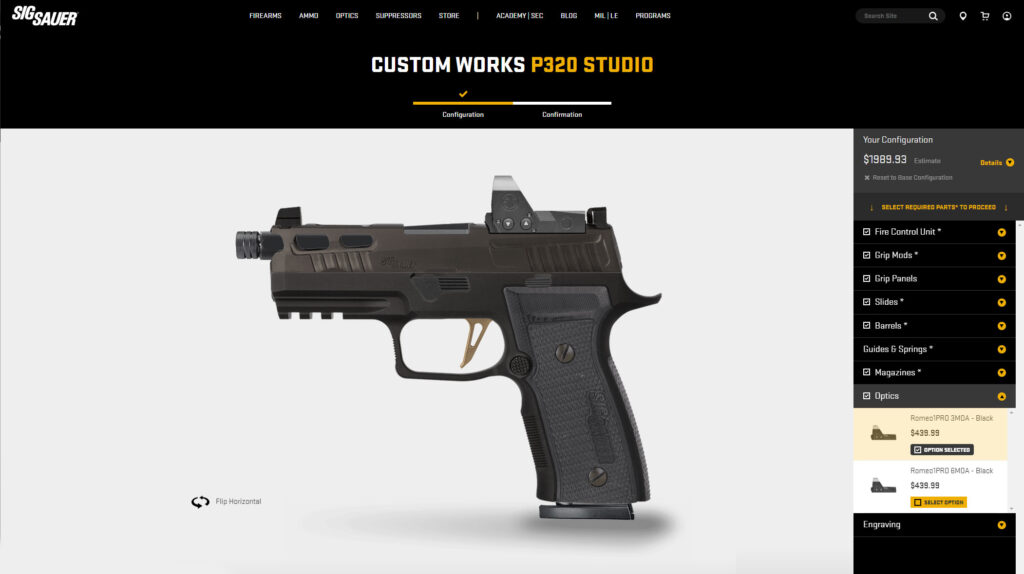

From here, you have to pick out a barrel. This is where you clearly get to see your gun come together via the graphic to the left. Sig grays out all incompatible options (based on your slide choice). Likewise, it displays what a protruding barrel would look like when installed, should you go that route.

Advertisement — Continue Reading Below

Lastly, you get to pick out your recoil spring assembly and magazine capacity. And again, stuff that won’t work is greyed out. If you want to top it off with a cherry, add your choice of optic.

To make it your own, Sig allows for laser engraving on either one or both sides. This allows you to add a touch of personal styling or maybe even to number a series you are building for yourself or your family.

Advertisement — Continue Reading Below

At the time of this writing, the listed lead time was 4-6 weeks. But honestly, that’s not a terribly long amount of time in this world. During this period, the parts are gathered up by an actual human being right at the Sig Sauer factory. It is then assembled into a finished pistol entirely by hand.

If you were wondering, yes, the FCU can be removed just like any other P320 from Sig. The point of this program is to serve gun owners, not the tyrants seeking to strip you of your freedoms.

Advertisement — Continue Reading Below

After assembly, your new gun is sent down to the range for test-firing and zeroing before getting the all-clear and being sent to your dealer.

Treated Like any Other Firearm

Once the gun enters the shop, it is treated like any other firearm with an obvious barrel length and caliber. However, Sig is currently only building 9mm custom pistols. The pistol can then be put right into the books without any other hoopla.

From here, all that’s left to do is satisfy any other state requirement that you might have and hit the range. Just remember to chuckle, “Okay, we’ll do it your way,” at least once from behind the wheel.

For more information, please visit SigSauer.com.

This article was originally published in the Personal Defense World October/November 2022 issue. Subscription is available in print and digital editions at OutdoorGroupStore.com. Or call 1-800-284-5668, or email subscriptions@athlonmediagroup.com.