Video

Image Gallery

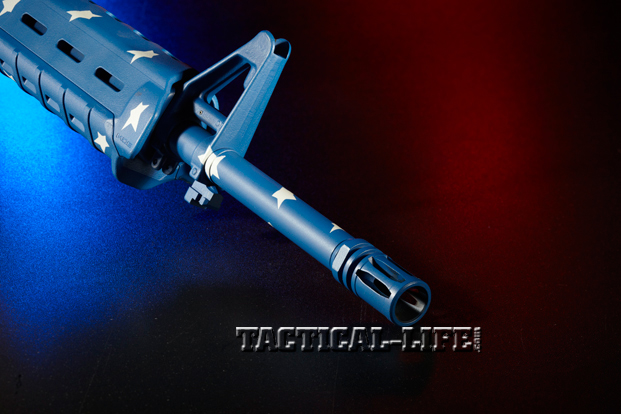

At a distance, this DuraCoat-finished SIONICS AR-15 gem resembles Old Glory waving in the breeze, but fill the magazine and you’ve got an ultra-reliable, CQB-ready battle carbine topped with a fast EOTech holographic sight.

Advertisement — Continue Reading Below

There are several reasons why good magazine editors enjoy long tenures with publishing houses. They often toil behind the scenes, working long hours to get the next issue off to the printer. The really creative of the lot—those who have true passion for the subject matter plus a solid understanding of and compassion with the readers—come up with great article ideas. When my editor, and friend of nearly 20 years, told me of team RF’s plan for celebrating AR ownership by bringing a few major manufacturers together to create a one-of-a-kind carbine, I was up to the task.

Teaming up with SIONICS (an acronym for Studies In the Operational Negation of Insurgents and Counter-Subversion, and at one time the name of a 1960s-era suppressor company) Weapon Systems and DuraCoat’s owner, Steve Lauer, we envisioned a unique AR-platform rifle with a patriotic paint job. The icing on the cake was an EOTech optic. To make the project even more interesting, it was decided to offer the rifle up for auction to raise money to donate to the MARSOC Foundation. First, Joshua Ellis, president of SIONICS, selected his company’s Patrol Rifle I for the project. Then, it was shipped out to Steve Lauer at Lauer Custom Weaponry. A couple of days after the rifle arrived, I followed with my camera gear in tow. Landing late at night in Eau Claire, Wisconsin, I was greeted with a foot of blowing snow. Slogging my way to nearby Chippewa Falls, the home of Lauer Custom Weaponry and DuraCoat, I spent the following day with company owner Steve Lauer while he gave me a short course in the application of a firearm’s finish. The first step is to disassemble the firearm into various parts. A chemical bath for the parts removes all of the residual oils to allow the finish to adhere. A shot or two of compressed air dried the parts quickly. Next, the parts were hung in front of a powerful exhaust fan to suck the overspray from the work area. Then the two-part base coat was mixed and loaded into spray applicators. After masking off areas that didn’t need a base coat, paint was applied. When needed, double coats were applied in progressively darker coats. Parts were hung in a oven-like cabinet to speed drying.

Once the base coats dried, it was time to start applying various tape masks to achieve the various patterns. More opposing coats were applied, masking tape patterns removed, and the parts went back into the drying cabinet. When a few of the parts didn’t satisfy Lauer, they were repainted to fit his ideas. Finally, the rifle was reassembled to reveal a splendid, patriotic red, white and blue American flag theme.

Advertisement — Continue Reading Below