When it comes to LE patrol rifles, lighter is always better. This has been one of the primary advantages of the AR platform, due to its aluminum upper and lower receivers and simple direct gas impingement system with its requisite few parts. For a weapon that may have a few pounds of extra gear attached to it, every ounce can count.

But, what if you were to employ a material even lighter and more advanced than aluminum? Well, Windham Weaponry has in its Carbon Fiber SRC (Sight Ready Carbine). At first glance, it looks like a standard AR-15-type rifle. But this AR has molded carbon-fiber-composite upper and lower receivers.

Without a magazine, Windham Weaponry lists its Carbon Fiber SRC at 5.85 pounds. The same rifle with an aluminum receiver lists at 6.3 pounds. The company has shaved off nearly a half-pound with the use of this cutting-edge material. If that doesn’t sound like a lot, try holding your rifle up to cover a hallway for a half-hour while your team clears the rest of a house. Weight matters. The longer you use your rifle, the more it matters. In today’s age of holographic sights, visible and IR lasers, mounted flashlights, and stocks and grips that carry extra batteries, the super-light AR rifle has found itself needing to go on a diet and shed a few pounds.

Gun Details

Advertisement — Continue Reading Below

The rifle arrived in a black hard case with a 30-round aluminum magazine, a sling and an operator’s manual. The barrel is chambered for the 5.56mm NATO and has a 1-in-9-inch twist rate. I prefer this twist rate because I rarely buy or shoot rounds that are heavier than 70 grains. In my experience, the 1-in-9-inch twist rate can handle any round up to 70 grains and generally will not increase pressures or cause throat wear as fast as a tighter twist. The MSRP for the Carbon Fiber SRC is a very reasonable $958.

I opened the case and, at first glance, the rifle looks like a normal M4. The rifle has a collapsible stock and a large, round forend with double heat shields. It comes with no sights. I think that is a huge plus. Odds are, almost everyone who buys this rife will do so with a purpose in mind. The guy who will use it on raids and entries needs folding iron sights and some type of red-dot sight. When Windham Weaponry decided to leave off the sights, they did so with the end-user in mind. Not adding iron sights helps keep the price down. I think most people will appreciate that.

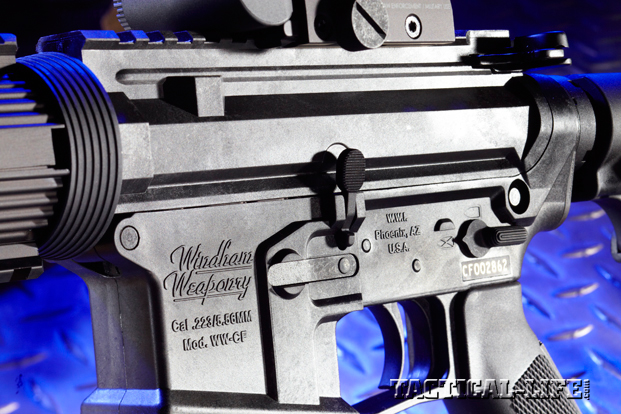

Next I inspected the rifle’s upper and lower receivers. Both have a matte, non-reflective black finish that is perfect for tactical operations. The area around the rear takedown pin is built up. The triggerguard is an integral piece of the receiver. The serial number is etched onto a piece of aluminum that sits above the pistol grip.

Advertisement — Continue Reading Below

I spoke with Jon Clark, marketing manager for Windham Weaponry, and he explained that both the upper and lower receivers are 40 percent carbon fiber and the rest is polymer. Parts of the receiver have been made thicker to hold up under stress. I pulled out a stripped, cast AR lower and began making comparisons. The walls of the Carbon Fiber SRC are noticeably thicker. The magazine well of the Carbon Fiber SRC is flared to make reloads faster and easier under stress. Other than that, the receivers appeared the same. The mil-spec pistol grip, trigger, hammer, pins and springs were identical on both.

Clark also explained that the Windham Weaponry Carbon Fiber SRC is 100 percent American made. There are a lot of AR-style rifle companies today that do nothing more than buy parts, put them together and put their name on it. Windham Weaponry makes nearly all of its parts in-house, and the company clearly takes pride in that fact. I noticed that Windham’s initials are etched onto the barrel. Then I saw it on the front of the gas block, then on the hammer. It is even etched onto the safety selector switch, and the Windham name is on the buttstock. This is a company that takes pride in the guns it produces.

I tried out the mil-spec trigger. It felt like most mil-spec triggers, with a bit of creep before it breaks. However, it felt different. Normally, the trigger and hammer pins rest against the aluminum frame. When you press the trigger, you feel metal on metal. Now the pins are resting against carbon fiber. The trigger feels like metal against polymer, and it is hard to describe better than that. I got out my Lyman electronic trigger pull gauge, and the trigger pull had an average weight of 6.41 pounds. This is very acceptable for a mil-spec trigger. Because the rifle was designed to fit mil-spec parts, virtually any aftermarket triggers will also fit in the receiver.

Range Time

Advertisement — Continue Reading Below

What really matters is how it functions. I grabbed my chronograph, a box full of ammo, slapped on a 3.5-10×50 scope and headed down to the American Shooting Center located here in Houston, Texas. With ranges out to 300 yards as well as firing points for over 200 shooters, it remains my go-to range for testing pistols and rifles.

After sighting in, I tested the Carbon Fiber SRC with standard military “Green Tip” ammo. This gun was designed to be a tactical weapon, so I thought it was the perfect round to start the evaluation. My best five-shot group measured 1.39 inches, and three groups averaged 1.86 inches. I tried a few other types of ammunition and tallied the results. While I have shot ARs that were more accurate, they were also more expensive. This rifle was designed to be a workhorse. It has the M4-style barrel stepdown for attaching an M203 grenade launcher, and it has an integral bayonet lug on the bottom of the pinned gas block. By the way, in my experience pinned gas blocks tend to be more reliable and less finicky than the type with setscrews. Everything about this gun was done with the end-user in mind. Dependability and less weight are the Carbon Fiber SRC’s calling cards. At the end of the test, the rifle had performed flawlessly with zero malfunctions.

Now that the accuracy test was over, it was time to put the rifle through its paces. I needed a good tactical course. As luck would have it, the Texas Narcotics Officers Association (TNOA) was sponsoring a 3-Gun match the following Saturday. I took off the scope and attached an EOTech XPS2 to the upper receiver. Neither the scope rings nor the EOTech left any marks on the carbon-fiber Picatinny rail. It was tougher than I expected. The course required quick loading, tactical reloads, rapid position changes, shooting from unconventional positions and engaging various-sized targets from 15 yards out to 75 yards. The temperatures were well into the triple digits. Virtually every semi-automatic shotgun there had multiple failures to cycle. Smoke wafted from the guns each time they finished shooting, and several people burned their hands on the forends of their rifles. The Carbon Fiber SRC took it all in stride. It never had a single malfunction of any kind.

Advertisement — Continue Reading Below

Final Thoughts

I didn’t win the competition, but I did finish near the top. None of my misses were the fault of the rifle. After the competition, I had a little more time to tinker with the gun. I liked the weight and I loved the dependability. The EOTech worked well for targeting. My only real concern was the forend. I am a big believer in using a white light on all tactical weapons. Its primary purpose is to help positively identify targets, but it also works great for distracting suspects. Clearing a house without a light makes about as much sense as doing it with your eyes closed. I needed a forend with some type of Picatinny rail. I replaced the forend with the Diamondhead VRS Drop-In Rail System. I then attached a Stark SE-5 Express Grip for quickly driving the rifle between targets. In the interest of keeping the rifle light, I simply added a Custom Defensive Products Bayonet Lug Accessory Mount and a SureFire X200 instead of some of the larger, heavier lights available today. The only things missing were backup iron sights. Since my goal was keeping the rifle as light as possible, there was only one choice: lightweight Magpul MBUS sights. The result was a tactical rifle that was lighter than any I had ever used, but certainly up to the task of conducting raids and clearing rooms.

People scoffed when the first polymer pistols made their appearance on the American market. Today, nearly every major pistol manufacturer offers polymer-framed handguns. Windham Weaponry just introduced an AR-style rifle with carbon-fiber upper and lower receivers, shaving weight without sacrificing dependability. For more information, visit windhamweaponry.com or call 855-808-1888.

Advertisement — Continue Reading Below