By now anyone in law enforcement or who follows the news has heard of the AR lower receiver built and successfully tested using a 3-D printer. This technology uses an additive process where a polymer is built up into the shape you want. Since the lower receiver is the only part that legally constitutes the “gun,” once you have that you can order the rest of the metal parts you need and build a functional AR. Under federal law, anyone can manufacture a firearm with no license or serial number as long as it is for personal use only and not sold or given away. Local laws may, of course, vary. It is the design of the AR itself that lends itself to having a nonmetal receiver. The majority of the pressure and force generated when the AR is fired is contained in the barrel, chamber, bolt and bolt carrier, reducing the pressure on the remainder of the rifle. This is why ARs use an aluminum receiver, which is lighter than steel but not as strong. But in an AR, it doesn’t need to be.

Of course this technology can be extended further, and using polymer as well as other nonmetal materials to manufacture upper and lower receivers is not new. Now Windham Weaponry has begun production of another such complete rifle, the Carbon Fiber SRC, a standard M4-style semi-automatic carbine with a direct gas impingement system chambered for the 5.56mm NATO. It’s the company’s use of carbon fiber in this AR that really sets it apart.

Gun Details

The Carbon Fiber SRC is being manufactured at a new 12,000-square-foot Windham Weaponry facility in Phoenix, Arizona, which it shares with local piston AR manufacturer Patriot Ordnance Factory (POF). In fact, Windham Weaponry recently announced a partnership with POF to produce these carbon- fiber rifles and .308 ARs. I have tested POF and Windham Weaponry firearms on several occasions, and a partnership between the two bodes very well for firearms enthusiasts and shooters.

Advertisement — Continue Reading Below

Carbon fiber offers some distinct advantages over aluminum for the patrol officer and shooter. Using a mix that is 40 percent carbon-fiber and 60 percent composite, each upper/lower receiver set is a full half-pound lighter than its aluminum equivalent. Production is also sped up by the use of molds to cast the more malleable material, which requires less fitting and finishing. These efficiencies also help reduce the production cost. This carbon-fiber/polymer composite has a high degree of strength and a natural lubricity, which means users can operate these rifles with less oil and thus less carbon fouling, dust or debris buildup, improving reliability and reducing wear and tear on the moving parts. This can come in especially handy when operating in environments with a lot of wind and airborne particulates. Polymers also act as thermal insulators and resist heat, like wearing gloves. Aluminum acts as a heat sink and absorbs and dissipates it. The practical effect is that both do a good job of keeping heat away from the user, but if both were left lying in the sun for a while, the polymer gun would feel less hot to the touch.

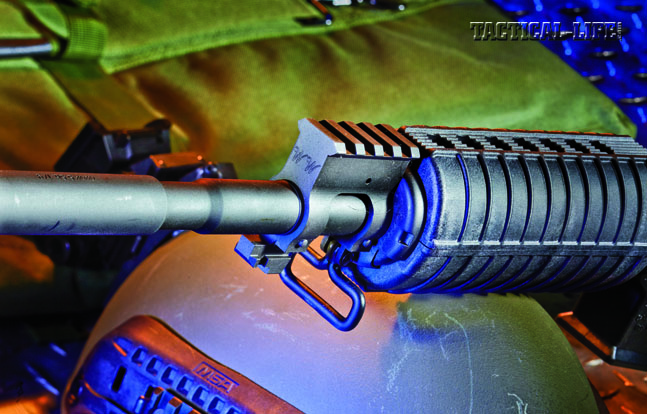

The receiver on the Windham Weaponry Carbon Fiber SRC is completely corrosion resistant and does not scratch like aluminum. Since there is no finish to speak of, any scratches that do occur will not expose bare metal underneath. The material is more malleable and less likely to break from a sudden shock or strike, which makes it more durable in that sense. However, shot-for-shot, an aluminum AR will outlast a carbon-fiber gun. In the build itself, Windham Weaponry took advantage of the fact that it was starting from scratch to design very distinctive-looking upper and lower receivers. Both appear beefed up and have an angular, billet appearance. The rifle also uses all standard AR parts with the exception of a slightly modified barrel nut. The upper receiver features a flattop design and a Picatinny rail at the rear and at the gas block. This is considered the company’s optics-ready option and offers users a clear sight picture when using low-powered optics, without a front sight post to get in the way. Of course, operators can and likely should install folding back-up iron sights.

The 16-inch, chrome-lined barrel has an M4 profile, is made from mil-spec 4150 chrome-moly-vanadium steel and is topped off with a removable A2 flash suppressor. Chrome-moly results in increased carbon content in the steel and adds significant strength and durability, both very desirable features in a duty rifle. The barrel has a fairly standard 1-in-9-inch twist rate, which on the range exhibited a distinct preference for lighter-weight bullets. Another mil-spec feature is the addition of M4 feed ramps at the back of the chamber. These are cut wider and lower than those for the AR rifle and are designed to improve reliable feeding of rounds from the magazine into the chamber. This can be especially important in carbines and under less-than-ideal conditions in which dirt, grime and moisture can be introduced. The CAR black plastic handguards feature double aluminum heatshields and were extremely effective at protecting the carbine-length gas tube, as well as my hand, from a hot barrel during two days of range testing.

Advertisement — Continue Reading Below

The bolt and bolt carrier are both phosphated and chrome-lined. The bolt carrier has a mil-spec M16 contour (as opposed to a cheaper commercial bolt), which is stronger and heavier, ensuring longer and more reliable operation, and is paired off with a standard carbine buffer. It should be noted that mil-spec M16 bolt carriers are legal to install in semi-auto rifles. The gas carrier key is also properly staked, which is especially important in a patrol rifle since screws that are not properly secured could become loose under fire.

The controls on the upper and lower receivers (dustcover, forward assist, bolt release, magazine release, charging handle, safety selector) are all located in the familiar places with nothing ambidextrous. The safety selector markings are pictographic and very distinct and appear on both sides of the receiver—it is easy to tell the condition of the rifle from either side. The triggerguard is oversized for use with gloves but remains integral and molded into the lower receiver. The lower receiver also has a very aggressively flared magazine well, facilitating faster reloads, and a bump-out protecting the rear takedown pin. I am not sure how necessary this is since the fit of the pins and the fit between the upper and lower receivers are extremely tight. The M4-type collapsible buttstock, which features the Windham Weaponry logo, has six positions for length-of-pull adjustment to accommodate officers with different statures or for use while wearing body armor. The stock was well installed and also an exhibited excellent fit with very little play. The lower receiver comes with a standard military-type plastic pistol grip with finger grooves and a slightly flared magazine well. The Windham Weaponry logo is prominently displayed on the left side of the magazine well and consists simply of the company name in a cursive type-script, doing away with more aggressive logos that may be off-putting to some department heads. The trigger was of the standard single-stage AR variety but exhibited a very crisp feel, although at 7.5 pounds, it was a bit heavy for my tastes. Still, this is within the mil-spec standard trigger weight and suitable for patrol use.

Range Time

On the range, the rifle was very lightweight and handy. I ran the rifle virtually dry right out of the box and experienced no malfunctions over two days of testing. Recoil was very light and manageable despite the light weight. I also tested several different types of magazines, both polymer and aluminum, from different manufacturers, and all easily dropped free. The only exception was the stainless steel magazines, which are slightly thicker than standard.

Advertisement — Continue Reading Below

I used the 3-9x40mm Trijicon TR20-2 AccuPoint scope and a mil-dot crosshair reticle featuring an amber dot to check for accuracy at 100 yards firing from a stable benchrest. Here, I encountered some surprising results. Using match-grade, 75-grain ammunition, my groups were averaging well over 6 MOA; as I went lighter, the averages got smaller. I also tested 69 grains, 60 grains, 55 grains and 50 grains, and finally my best results were with the 35-grain Winchester Ballistic Silvertips, which averaged about 1.5 inches at 100 yards. A higher rate of twist in the barrel rifling, such as 1 in 7 inches, better stabilizes heavier bullets, and a low rate of twist works better for lighter bullets. This Carbon Fiber SRC has a very standard 1-in-9-inch twist rate, and I have tested other rifles from Windham Weaponry with the same barrel twist, but I have never experienced such a high level of accuracy discrepancy based on bullet weight. Sticking with standard 55- to 62-grain ammunition, this rifle should average between 2 and 3 MOA, which is certainly suitable for the patrol-rifle role.

Final Notes

At well under 6 pounds, this is the lightest AR carbine Windham Weaponry manufactures, and it comes ready for the user to add his or her own optics and sights. The weight reduction and adjustable stock makes it easy and comfortable to handle for officers of different builds, and the carbon-fiber composite construction makes it economical for officers or agencies on a budget. And don’t forget that the carbon fiber will help keep the rifle from getting too hot when it sits in a patrol car all day. Add to that the gun’s exemplary reliability and you have one outstanding patrol carbine. For more information, visit windhamweaponry.com or call 855-808-1888.