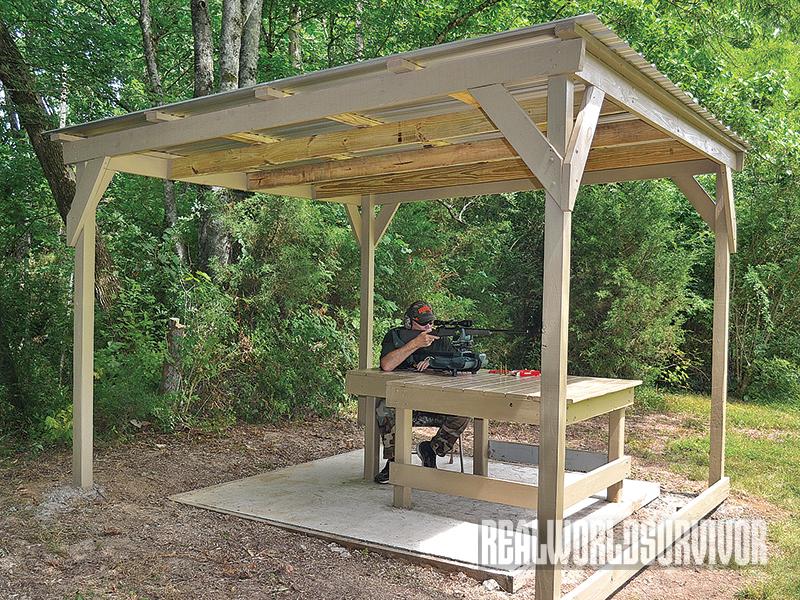

You finally got around to building a permanent shooting bench in the back 40 that now gives you a sturdy platform to sight-in your rifles, check handloads and simply have fun doing some serious plinking. However, after a few months, you notice that even though you made the bench from treated materials, it’s showing some signs of wear due to exposure to the weather. At the same time, you wish you had shade over the bench during the hot months. It would also be nice to have a roof over the bench so when it’s raining, the shooting doesn’t stop. This is where a DIY shooting shed comes in handy.

A DIY Shooting Shed

My sons and I went through the same wish list soon after we built our permanent shooting bench on our farm, and after some discussions, we decided we needed a strong shed roof over our large bench that would give us, and the bench, protection from the sun and rain.

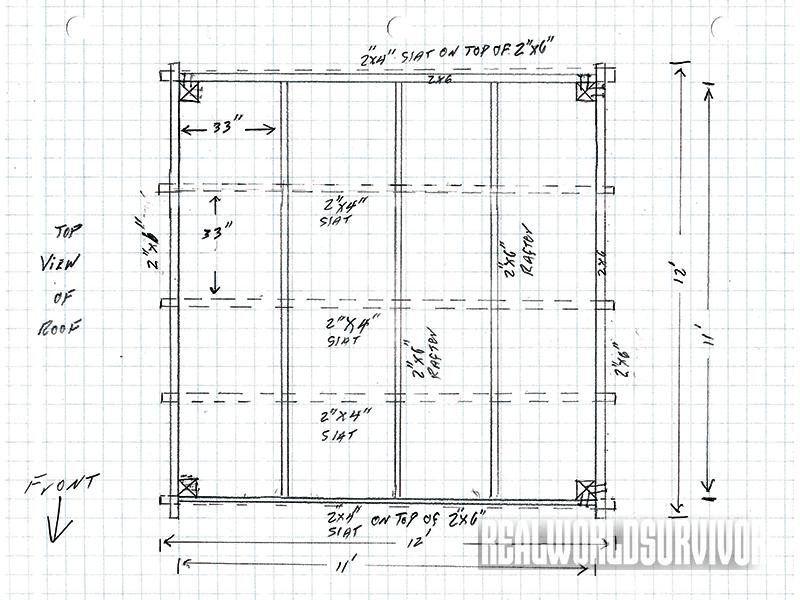

Since snow accumulation in our region is not a problem and a steep pitch is not required, we decided on a simple, gentle-sloping, shed-style roof. We had already poured an 8-by-8-foot pad around the bench to give us a clean place to sit and shoot, so we decided on building a 12-by-12-foot shed roof centered over the bench and pad.

Advertisement — Continue Reading Below

We knew that if the roof was to be a perfect 12-foot square, with a 6-inch overhand on all sides, the four 4×4 corner posts must be placed 11 feet apart with the center of the square being in the center of the existing shooting bench. My son Jeff came up with a simple template he made from four of the 12-foot 2x4s we had purchased to use as slats. It was a square that measured exactly inside 11 feet by 11 feet.

Making the Cuts

We found the center of the shooting bench and sat the 11-by-11-foot square over the bench and concrete pad, with the template center matching it. With the 11-by-11-foot square on the ground, we painted the ground orange with spray paint in each corner. That would be the location of each of the corner posts. We lifted the 2×4 square off and disassembled it so the boards could be used as slats.

Since we wanted each 4-inch-by-4-inch-by-12-foot corner post to be in the ground 24 inches and anchored in concrete, we rented a one-man power auger. It gave us clean holes and saved a lot of digging time as the site had lots of roots and rocks in the ground.

Advertisement — Continue Reading Below

Once we dug the holes to the desired depth, we used a level and steel tape to position each post at exactly 11 feet apart, outside to outside, and to be perfectly plum. Then we poured in the Quikrete and water, and again checked the post, both at ground level and at the top, for distance and to be plum. Satisfied with the post positioning, we gave the Quikrete two days to set up.

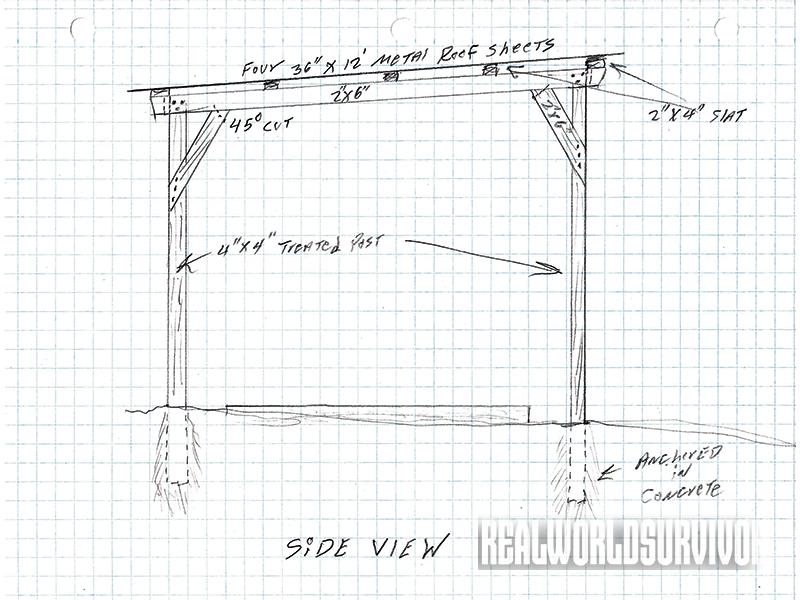

With the four-corner posts solidly in place, we were ready to cut the post to length. Since the site sloped about 1 foot from back of the shed site to the front, we decided to cut the two back corner posts at 8-foot lengths, and to cut the front post at a place that would give us an 8-inch roof pitch from front to back. We determined this by marking both back posts at 8 feet. Then we pulled a string with a string level attached to the level point on the two front posts. We marked this point on each post and measured 8 inches above that, making this the cut point. Using a chainsaw, we cut all four poles to length.

Placing the Girts

Next, using ¼-inch lag bolts and washers, we attached a 2×6 board measured out to 11 feet, 8 inches; it ran from the higher front post to the lower back post on the outside. We positioned the board so that it was just slightly higher that the highest point on top of the post. It gave us 4 inches of overhang in the front and back of the shed to support a rafter near the edge of the metal roof. Across the two front posts and the two back posts we attached, on the outside, using ¼-inch lag bolts, a 2×6 board cut to 11 feet in length. With this done, we had strong girts all around the roof to attach the rafters and slats.

Advertisement — Continue Reading Below

Since we get some occasional strong winds at our range, we elected to brace the girts to each post. We did this at each corner from two directions with 2-by-6-by-30-inch boards cut at 45-degree angles and attached with ¼-inch lag bolts. This also braced the shed roof from any side-to-side motion.

With the girts securely fastened in place, we were ready to cut and bolt in place the three inside 11-foot 2×6 rafters. Since the side girts would serve as the outside rafters, we only needed three interior rafters (with 33-inch, on-center spacing). We attached these to the front and rear girt using ¼-inch lag bolts.

For strength, we elected to use treated 12-foot 2×4 slats to which we attached the metal roofing. We also placed these five slats with on-center spacing of 33 inches. We attached them to the rafters with 3½-inch exterior-grade deck screws. Lastly, we needed a slight angular cut on each rafter to get the rafters to fit the girts. This angle will depend upon the pitch you give the roof.

Advertisement — Continue Reading Below

Raise the Roof

The final step in completing the shooting shed was to place the metal roofing panels to the slats using 1¼-inch washer roof screws. As the metal roofing went up, we were glad we started with well-placed posts and careful measurements on the girts and slats, as the metal panels fit exactly and gave us a 6-inch overhang as we had planned.

There are several options to consider for the ground cover under a shed roof for a shooting bench. It can be left as bare ground, it can be a concrete floor or, in our case, since we already had a square, 8-foot concrete pad in place, you can fill it in with crusher-run gravel. It has been my experience that even with a roof, if there is much slope, rain will cause the shooting shed to be a muddy mess, so the concrete or gravel option is usually best. Also, it makes the recovery of brass and cleaning up much easier.

Under our shooting shed, we filled in around the concrete pad with crusher-run gravel and it works well. We are also in the process of painting all the wood in our shed not only to give it a better look, but also to help keep carpenter bee damage to a minimum.

Advertisement — Continue Reading Below

Materials List for Your DIY Shooting Shed

Since the shed sees all types of weather, all wood products selected were treated, exterior-grade products. All screws and lag bolts were exterior grade.

- (4) 4-inch-by-4-inch-by-12-foot treated posts

- (9) 2-inch-by-6-inch-by-12-foot treated boards

- (5) 2-inch-by-4-inch-by-12-foot treated boards

- (4) 36-inch-by-12-foot galvanized sheet metal roof

- 1 box ¼-inch-by-3½-inch lag bolts and washers

- 1 box 3½-inch deck screws

- (4) 50-pound bags of Quikrete

- 1 box 1¼-inch washer roof screws

- 1 can of orange spray paint

Tools It Takes

- Porter Cable 20V ½-inch drill/driver

- Oregon 40V chainsaw

- Porter Cable 20V impact drill/driver, ratchet

- Porter Cable drill bit set with Phillips-head driver

- Black & Decker Workmate portable vise/table

- Porter Cable circular saw

- Porter Cable reciprocating saw

- Long level

- String level and masonry string

- Safety glasses

- 25-foot steel tape

- Stepladders • Hammer

- One-man power auger (rented)

- Speed square

- Leather gloves

- Carpenter’s pencil

Project Overview

- Skill Level: Intermediate carpentry skills

- Required Labor: Two

- Estimated Cost: $400

- Completion Time: Three to four days (includes time for concrete set)