There’s a lot going on when you squeeze the trigger of an AR. When the sear breaks, you better know that your ammo is up to the task, especially if you handload. Add these tips to your loading repertoire to build more consistent, reliable and accurate ammunition.

1. Good Neck Tension

Consistent neck tension refers to the case mouth applying the same pressure and friction to the bullet from one round to the next. Consistent neck tension results in a repeatable powder gas pressure curve, and similar muzzle velocity and trajectory—meaning your slugs will land in the same place. Equally as important, a consistent pressure curve means that your AR will cycle the same from shot to shot. Military loads, and some factory loads, attempt to achieve this by crimping their bullets in the case.

Advertisement — Continue Reading Below

RELATED STORY: 7 Reloading Accessories For Creating Accurate, Reliable Ammo

“Crimping the case is one option, but it means you will distort an expensive benchrest bullet,” said John Paul Gangl, owner of JP Enterprises. He went on to say that new brass cases, once-fired cases or cases of the same headstamp should only be used for reloading an AR in his opinion.

2. Case Annealing

Advertisement — Continue Reading Below

Repeatedly firing and loading a brass case causes the case neck and shoulder area to become work-hardened and brittle. A telltale sign is that the case necks start to crack on firing.

One way to extend the life of your cases is to anneal them. The simplest way to accomplish this task is to use a propane torch to apply the correct amount of heat and then drop the case into a cool bucket of water. Fancy case-annealing compounds are available that turn a certain color to indicate the proper amount of heat has been applied during the process.

When I’m annealing cases, I don’t have time to waste on this extra step. My method is to anneal in a darkened room. This way, I can remove the case from the heat source just as it begins to glow red. Don’t overdo it, since too much heat dangerously over-softens the brass and reduces case life, too.

Advertisement — Continue Reading Below

3. Case Gauges

Acquiring case gauges for the calibers you reload is the best way to check that case length, headspace and case circumference dimensions are within specifications. Cases can be checked before and after loading to determine if your reloads will work in a semi-automatic chamber. It’s a pretty good bet that after the fourth reloading, your cases will have reached the point of being out of spec.

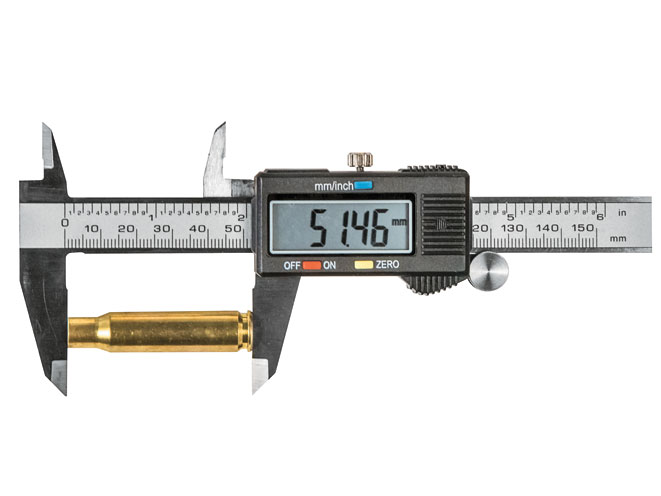

4. Check Your OAL

Advertisement — Continue Reading Below

The overall length, or OAL, is the measurement of the loaded round. The SAAMI specification for the 5.56mm NATO cartridge is 2.26 inches, which allows it to fit and feed from a USGI AR-15 magazine. As an added measure, seat bullets to a maximum of 2.25 inches for more reliable function, and this OAL also corresponds to what I find ideal when shooting bullets like the heavier Sierra MatchKings and Berger VLDs.

5. Headspace Issues

Headspace is the distance from the bolt face to the part of the chamber that stops the forward motion of the cartridge case. In AR-platform rifles, that is typically the shoulder. Excessive headspace occurs when a loaded round’s shoulder sits too far back from the chamber shoulder. Upon firing, the case stretches and may separate from the case head. This malfunction will lead to a stuck case in the chamber and probably a trip to your local gunsmith. Too little headspace will keep an AR’s bolt from completely engaging the barrel lugs, which can also lead to problems. A bolt not completely in battery when a cartridge fires can cause lugs to shear off or crack bolt heads. Insufficient headspace, at some point, will prevent the rifle from firing at all.

Advertisement — Continue Reading Below

RELATED STORY: RCBS Precision Mics – Measuring Headspace & OALs

Sized or loaded cases can be checked with a case gauge. If the case is too long, then you need to screw the die down into the press until the case comes within spec. If your press arm is lowered and the die is touching the shell holder, you may have an issue in regards to the die itself. This could be a situation where you need to employ a small base sizing die to remedy the situation. If you have a progressive press and a multi-stage shell plate, you may have a similar issue. Cases that are too short require a more simplified fix. Just screw the sizing die out of the press until you solve the problem.

6. Lose The Fat

Advertisement — Continue Reading Below

If your sized cases are too fat to fit into the chamber of your AR, you can’t put them on a diet. You can, instead, acquire a set of small base sizers to squeeze the case body back to working dimensions.

7. Depth Dummy

Depending on your bullet’s profile, the depth to which it is set in the case may cause it to engage the barrel’s rifling lands. If the bullet pre-engages the lands, it may cause problems. The projectile may be pulled from the case if a loaded round is extracted, dumping powder into the receiver and leaving a bullet in the bore. A bullet wedged tight in the lands may also spike pressures when fired, potentially causing damage to the rifle. The easiest and safest way to check bullet seating depth is to make a “dummy” round and check its function in the chamber. Inspect the bullet visually to find telltale signs of rifling land marks on the bullet. Also, measure the OAL of the dummy round before and after chambering.

RELATED STORY: Reloading 101 – How To Load Your Own Ammunition

8. High Primers

Visual inspection of loaded rounds is one way to check for high primers, which can cause malfunctions in your rifle. A round with a high primer may “slam-fire” when the bolt springs forward, or fail to fire at all. Another method to check for high primers is check during final loaded round inspection with a case gauge. You can get the hang of feeling for high primers pretty quickly.

9. Trimming The Excess

When fired cases go through the firing and sizing process three to five times, there’s a pretty good chance that the case length is excessive. That’s when a case trimmer comes into play. A number of case trimmers exist, and I’ve used an old hand-cranked RCBS for years. I got tired of numb hands and arms after a session on the old-style trimmer, so I upgraded to a Hornady Lock-N-Load Power Case Prep Center. It’s much faster and doesn’t work me to death any more.

FOR MORE INFORMATION

Hornady

http://www.hornady.com; 800-338-3220

RCBS

http://www.rcbs.com; 800-379-1732

SAAMI

http://www.saami.org