Most American shooters probably aren’t familiar with the name Arex. Established in 1994, the Slovenian company produces products for the defense industry and, at one time, for FN Browning. In 2012, a significant investment by owner Ivan Kralj in a cold-hammer-forging machine gave the company all the equipment it needed to produce a complete pistol.

Last year, I reviewed the Arex Rex Zero 1S and was impressed with its quality and accuracy. Imported by the FIME Group out of Las Vegas, the Rex Zero 1S gave shooters in the United States a chance to see what a small European company whose intense focus on quality control is capable of.

Advertisement — Continue Reading Below

When I contacted the FIME Group about getting a test sample of the Rex Zero 1S, I learned Walker English was part of this new company as the director of sales. I’ve known Walker over 20 years, and most of that time the retired Marine was with Arsenal. He informed me that Arsenal’s owner, Vartan Barsoumian, had set up FIME for importing the new Slovenian gun. I had a test sample almost immediately. I shot it, wrote it up and had nearly forgotten the Rex Zero 1S as I moved on with other projects. That is until Walker called me a couple months ago and invited me to tour the Arex factory in Ljubljana, Slovenia. An all-expenses-paid trip to Europe to hang out with some other gun writers and meet the people that made the cool pistol? I was all in!

When I landed in Slovenia, I was met by Vartan Barsoumian and FIME’s newly named vice president, Brian Hardy. It was just a 40-minute drive from the airport to our hotel. The countryside enthralled me with its rich green hills, small farms, quaint red-tiled-roof villages and churches.

The Military Arms Channel’s Tim Harmsen made the trip along with his videographer. So too did The Firearms Blog’s James Reeves, American Rifleman’s B. Gil Horman and Cheaper Than Dirt’s Dave Dolbee. I was in good company!

Advertisement — Continue Reading Below

We arrived at our accommodations, the Hotel Grad Otocec, an honest-to-God European castle, with an accommodating staff standing by, poised to help in any possible way. My room, despite being centuries old, was amazing in every respect, including the view of the river from my window. This is not quite what I’ve grown accustom to as a gun writer!

After a pleasant Sunday tour of downtown Ljubljana, Slovenia’s capital city, and a dinner with Arex and FIME personnel, it was time to get to work. Monday morning found us at the Arex factory. After a brief welcome from Arex owner Ivan Kralj, we were introduced to other company executives, including Product Director Grega Kralj, Ivan’s oldest son. Established in 1994, Arex currently has over 120 employees and 25,000 square feet of manufacturing space. The company has been ISO 9001 rated since 2008.

Behind The Curtain

I’ve been on plenty of factory tours here in the United States. The one thing that impressed me about the Arex factory was its cleanliness. No oil-stained concrete floors or cutting fluid leaking from the machines or piles of machine chips laying on the floor. Every part of the factory that we viewed was spotless, and raw materials and components were meticulously organized.

Advertisement — Continue Reading Below

Arex’s tool shop is a very important part of the facility. It makes all prototype parts and fixtures for production. Ivan started a program to bring in interested high-school-aged kids to teach them the fundamentals of machining on the manual machines. He has a high retention rate of these highly motivated and enthusiastic youngsters. We met several former students who now hold key positions in production or quality control.

Among the machinery is an EDM wire cutter and five-axis milling machine. “If you make your own tools, you control the entire manufacturing process,” Walker English said.

The quality-control department occupies a significant portion of the factory’s floor. Each manufactured part is inspected, and batch numbers are machined onto them to track and monitor tolerances. Even the tools used to manufacture products have files that record their wear and work history.

Advertisement — Continue Reading Below

Smooth Operation

The facility is in an old building, but it’s been modernized with several expansions. For instance, the cold-hammer-forging machine, about the length of a small plane, is housed in a separate area that required its own 10-foot-deep concrete foundation to prevent the machine from collapsing the building with its heavy vibration. Arex’s two indoor ranges, and the hallways leading to them, were trenched from above and had their concrete walls poured very thick.

Arex personnel test-fire each gun, starting with two overloaded rounds that possess 35-percent more pressure than standard ammunition. After a visual inspection, the gun is then fired with one magazine of ammunition in single-action (SA) mode. Another magazine is fired in double action (DA). The technician then fires another 10 rounds to zero the gun’s sights. A total of 32 rounds must be fired without failure for the gun to ship.

What’s Next

With our facility tour completed, we adjourned to a conference room to see what’s next for Arex. Since I first wrote about the Rex Zero 1S, Arex has introduced a compact model, the Arex Rex 1CP, with a shorter barrel, slide and frame. Both of these guns will be offered in an electroless nickel finish with the same wear and corrosion resistance of Tenifer. Pricing shouldn’t be more than 10 percent of the standard gun’s cost.

Advertisement — Continue Reading Below

Arex displayed some sample guns in the conference room outfitted with walnut grip panels, and we were told that these should be available in late fall of 2017. FIME will also offer Hogue G10 grips in green, Flat Dark Earth and black. Additionally, TruGlo night sights will be available for all offerings.

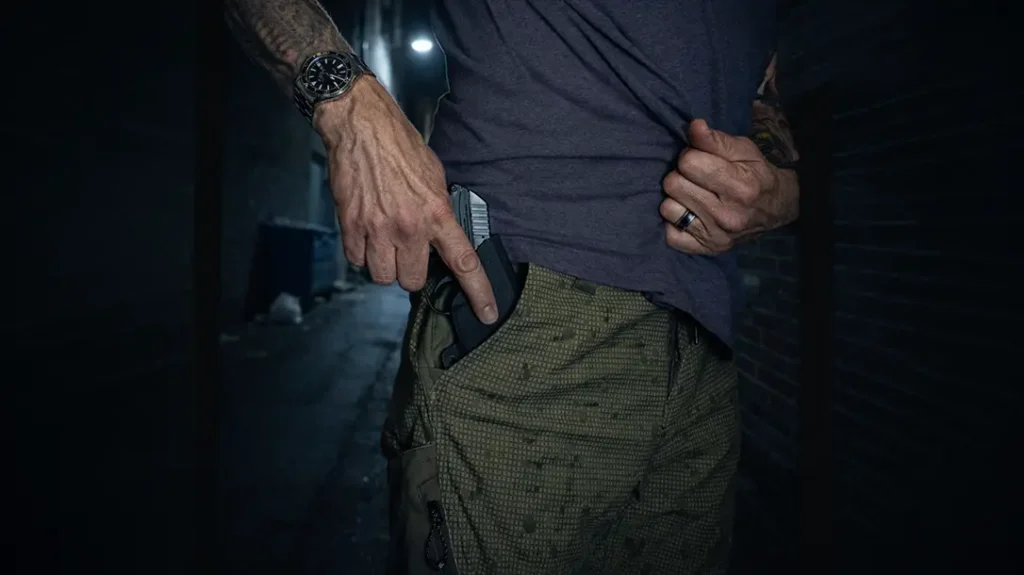

In an effort to add value for consumers, FIME will give a free polymer paddle holster to everyone who has purchased a Rex Zero 1S before December 31, 2017. The holster features an easy-on/off paddle that is adjustable for both cant and retention. The holster will work with both the Rex Zero 1S and 1CP.

“Our customers are the most important focus of our company,” Walker said. “We wanted to kick off the accessory lineup with something that not only says ‘thank you’ to the tens of thousands of customers that initially bought our pistol, but also shows that we are honored and humbled by the fact that they have chosen a Rex to defend and protect their lives and their families lives over our competition.” Customers can submit the required information online at fimegroup.com.

Advertisement — Continue Reading Below

Alpha Awesomeness

The one new product that made everyone sit up and take notice was the Arex Rex Alpha. It’s Arex’s entry into the competition field. The company’s goal was to build a race gun for IPSC as well as USPSA competitors. The Alpha’s frame is machined from recoil-dampening steel, which should also hold up to the tens of thousands of rounds a shooter will put through it during its lifetime. The slide has been extended to 5 inches. It sports lightening cuts so that it will cycle reliably with minor-powered 9mm ammunition. For targeting, the pistol uses a fiber-optic front and a fully adjustable rear sight.

The Rex Alpha retains the ambidextrous magazine release of the Rex Zero 1S, which Arex has drilled and tapped to accept an extended paddle for rapid reloads. Extended manual thumb safety paddles have also been used so the shooter does not have to shift their firing grip to engage or disengage them.

The Alpha’s grip frame has been thinned. The gun has a high-swept beavertail and an undercut triggerguard to give the shooter a high hold on the gun to minimize muzzle flip. Checkering is cut into the frontstrap, and the magazine well is flared for fast, fumble-free reloads. The flaring opens the magazine well by approximately 50 percent, so it is a worthwhile feature.

Reigning On The Range

The Rex Alpha felt great in my hand. I was certain that I’d be able to shoot it quickly and accurately. Turns out I didn’t have to wait long to try it.

Our last full day in Slovenia found us at Ivan Kralj’s private range. Built on a hill, like everything else in Slovenia, the range will eventually feature a large lodge, for which he just poured the foundation, as well as sporting clays and a rifle range. Realizing the underground range at the factory wouldn’t suit our needs, Kralj had a crew move some earth around and built three nice pistol bays for us.

In one bay, there were several variations of the Rex Zero 1CP model and in another there was the new tactical model, the Arex Rex Zero 1T, outfitted with a suppressor and red-dot sight. The first bay I went to contained the new Rex Alpha. Arex’s pro shooter, Maks Hvalec, stood by to detail the gun for us again and put on a small demonstration of his and the Alpha’s abilities. As I watched him shoot at an array of targets, I noticed the muzzle hardly moved. He explained his rounds were loaded at just above the minimum power factor, yet the slide cycled smoothly. When I finally got to shoot, I noted that the DA pull felt to be between 7 and 8 pounds. The SA pull felt like it was just over 2 pounds.

Though it has been years since I competed in USPSA matches, I shot the Alpha quickly and accurately. The red fiber-optic sight never seemed to recoil off target, making transitions between targets very easy. I did reloads from the bench, with tapered magazines easily sliding home.

Thumbs Up

I like the Alpha a lot and I wasn’t alone in my sentiments. American Rifleman’s B. Gil Horman said, “I need to own that gun. I love the way it shoots!” When I asked him if he shoots competitively, he said, “No, I just enjoy shooting an accurate centerfire gun with hardly any recoil. But if I owned an Alpha, I might have to start shooting matches.”

Journey’s End

The event finished with a superb dinner prepared by Ivan Kralj at his hunting cabin just a short drive from his range. It included homemade wine; locally made cheeses; salamis and breads; mushroom soup made with mushrooms collected from Kralj’s forest; and a main course of barbecued chicken and pork. It was the perfect ending to a wonderful event.

Arex’s Rex Zero 1S, 1CP, 1T and new Alpha pistols will build the base for many more new and intriguing products from this small Slovenian company whose main goal is to build flawless guns and sell them for an affordable price. Keep an eye on Arex; the company is sure to build something that will impress you! The FIME Group, based in Las Vegas, Nevada will be the exclusive importer for the United States.

Arex Rex Zero 1S Specs

| Caliber: 9mm |

| Barrel: 4.25 inches |

| OA Length: 7.7 inches |

| Weight: 29 ounces (empty) |

| Grip: Polymer |

| Sights: Three-dot |

| Action: DA/SA |

| Finish: Matte black |

| Capacity: 17+1 |

| MSRP: N/A |

Arex Rex Zero 1S Performance

| Load | Velocity | Accuracy |

|---|---|---|

| Aguila 124 FMJ | 1,109 | 1.13 |

| Black Hills 115 JHP | 1,264 | 1.87 |

| CorBon 115 JHP +P | 1,384 | 1.54 |

| DoubleTap 77 JHP | 1,560 | 1.46 |

| Hornady 147 JHP | 994 | 0.87 |

*Bullet weight measured in grains, velocity in fps by chronograph and accuracy in inches for best five-shot group from 25 yards.

For more information, visit fimegroup.com.

This article was originally published in the March/April 2018 issue of “Combat Handguns” To order a copy, visit outdoorgroupstore.com.