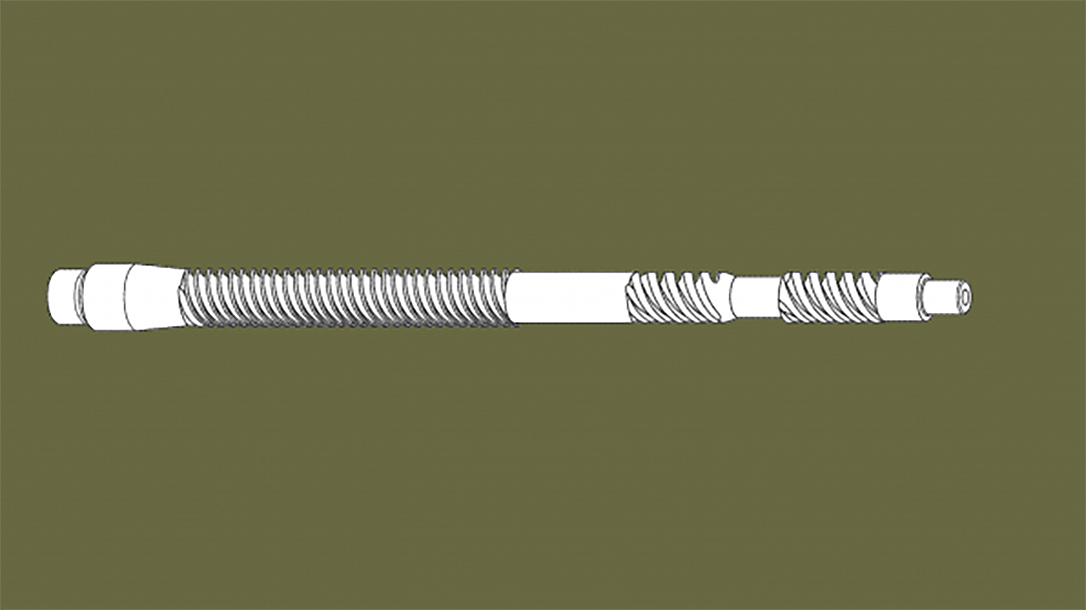

News out of the Army today describes a new spiral M4A1 barrel developed by a pair of small arms engineers. The U.S. Army’s CCDC Armaments Center developed the new barrel to deliver extended cyclical firing.

Army Develops Spiral M4A1 Barrel

The Army received a 15-year design patent, available to license to businesses to manufacture the new heavy barrel design, according to techlinkcenter.org.

Advertisement — Continue Reading Below

The Army gave Thomas Grego and Adam Foltz credit for designing the new barrel. The work took place at the famous Picatinny Arsenal in New Jersey. The barrel features helical, or spiral, fluting across three distinct areas. The fluting increases the exterior surface of the barrel. Meanwhile, it reduces the overall weight, according to techlinkcenter.org.

According to the Army report, the barrel dramatically reduces the risk of barrel failure or premature ammunition detonation, or cook-offs. It diffuses heat faster than a conventional M4A1 heavy barrel. Soldiers reported those barrels failed during combat in Afghanistan.

“(The M4A1) allows us to fire a better suppressing fire,” Lt. Col. Terry Russell told the Army Times in 2015. “At some point, a barrel is going to bend. It could be solid steel, but as soon as you reach a certain heat point it’s going to do some damage to the barrel. … But (the improved barrel) would have helped out to a certain degree.”

Advertisement — Continue Reading Below

The barrel fluting includes fin spacing and a thickness optimized for heat dissipation and weight, reported techlinkcenter.org. The fin height gradually tapers down. It will be interesting to see where this goes.