At the beginning of 1990, the Yugoslav People’s Army (YPA) was the military of the former Socialist Federal Republic of Yugoslavia (SFRY). When Croatia began moving towards independence, YPA commanders expected that Croatia would use the equipment of the Territorial Defense Force (TO) to build its own army. Consequently, on April 14, 1990, the YPA’s general staff ordered that all TO weapons be confiscated, minimizing expected resistance. But this order did not include the police forces, which were under the Ministry of the Interior. Thus, Croatian authorities decided to strengthen the police and provide better armaments, making it the nucleus of a future independent army. For instance, on November 21, 1990, they obtained 5,000 Czechoslovakian CZ 85 semi-automatic pistols chambered for the 9mm through a Panamanian company, Olympus Trading, Inc.

The preparations for the Croatian National Guard (ZNG) began on April 12, 1991. The Croatian authorities considered arming a police force for military capabilities in case of future confrontations with the YPA. Since it was illegal to establish a separate military in a constituent of the SFRY, the ZNG was planned as part of the police force under Croatia’s Ministry of the Interior. The Croatian Parliament amended the Internal Affairs Act on April 18, and the ZNG was formally established on April 23, 1991. The ZNG was formally under the Ministry of the Interior, but its founding legislation stipulated that the Ministry of Defense would command it.

Advertisement — Continue Reading Below

Croatia declared independence on June 25, 1991. However, the declaration itself came into effect on October 8, 1991. In the meantime, political tensions escalated into the Croatian War of Independence.

On September 20, 1991, the Croatian Parliament enacted the Defense Act, specifying that the ZNG and the Croatian Army (HV) comprise the armed forces of the Republic of Croatia. At the same time, the armed forces were formally designated as part of the Ministry of Defense rather than the Ministry of the Interior. The legislation also designated the TO reserve units as a constituent part of the ZNG reserve force. On October 8, the Defense Act was amended, with the ZNG redefined as part of the Croatian Army. ZNG reserve units became the HV reserve, named the Home Guard, leaving the ZNG an all-professional force. The ZNG was renamed the Croatian Army on November 3, 1991.

Croatian Arsenals

During its development, the ZNG experienced many problems, including a shortage of weapons. Thus, more and more amateur builders, working in primitive home workshops, started making mainly unsuccessful patterns of pistols, rifles and submachine guns. Of these small, private factories, only one from the small town of Ozalj survived and became known internationally.

Advertisement — Continue Reading Below

IM-Metal was founded in 1990 by Marko Vuković and Ivan Zabcic. The firm’s Ozalj operations were in central Croatia, approximately 40 miles southeast of Zagreb, the capital city of the newly formed country.

Vuković began his career in a prominent Yugoslav company, Jugoturbina, in the neighboring town of Karlovac. Jugoturbina was part of the military-industrial complex, producing engines, turbines and pumps for the Yugoslav navy and air force. It also made armored fighting vehicles. Vuković left that firm and went to Switzerland for advanced studies, where he worked on motor inspection and manufacturing at the Office of Development. After his return to Croatia, he completed a technical management program in Maribor, Slovenia. Meanwhile, Jugoturbina expierenced a big crisis and was unable to satisfy market demands. Vuković and Zabcic saw their own chance under the circumstances and formed IM-Metal, making motorpumps, machine parts and various assemblies.

Also, the newly formed ZNG was still short of modern pistols, which created another opportunity for IM-Metal. By April of 1991, a team headed by Vuković completed the final drawings and specifications for the first Croatian pistol. It was chambered in 9mm. A prototype batch of 20 test pistols was produced just one month later. The weapon then became known as the “Prvi Hrvatski Pistolj Marko Vukovic (PHP MV, or “First Croatian Pistol by Marko Vuković”)

Advertisement — Continue Reading Below

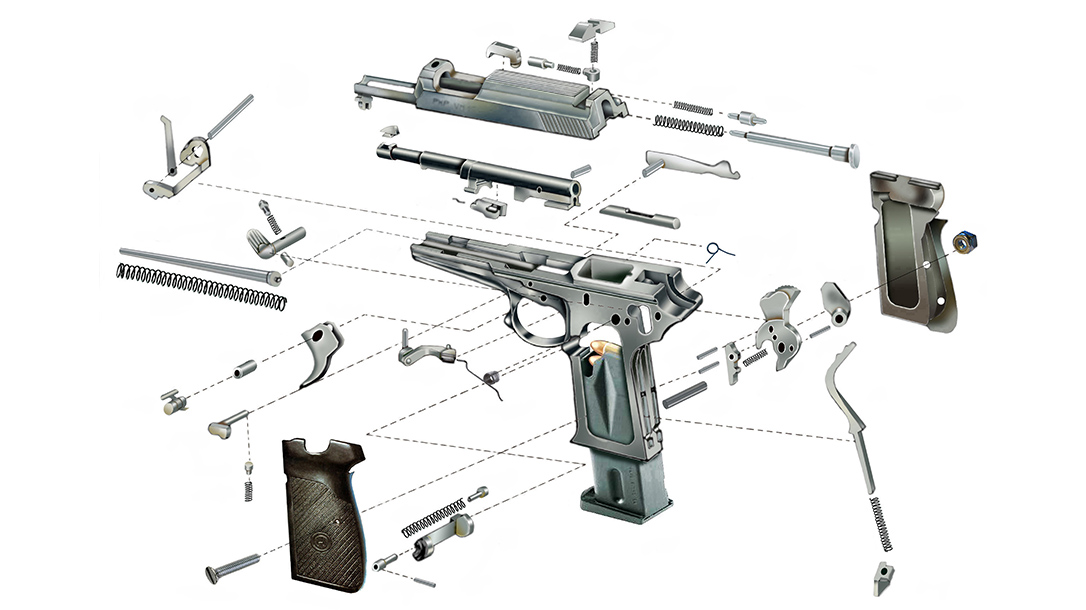

Meet The PHP MV

The PHP MV was a short-recoil-operated, locked-breech pistol. By design, the pistol represented a combination of the German Walther P38 and the Italian Beretta M1951 Brigadier, a precursor to the now-ubiquitous Beretta 92. The PHP MV was designed as a large-framed, double-action/single-action (DA/SA), duty-sized handgun. It used a locked barrel with the Walther falling-block system. The barrel stands on two “pedestals”—one with its back surface even with the breech face and another with its front surface even with the front of the slide and frame. The forward pedestal was relieved by about 0.188 inches to move the barrel over the takedown lever in the closed position, limiting the barrel’s travel. Rotating the takedown lever frees the barrel. In fact, Beretta copied the Walther system only conceptually.

The PHP MV’s other features and appearance were similar to the Walther P38. An open-slide design, combined with a straight-recoiling barrel, produced good accuracy and virtually jam-free cycling. The Walther falling block reduced the mass of the slide. It also kept the barrel in one place so that feeding was more consistent. Also, the locking-block design allowed for the open slide and 180-degree ejection port, which promoted reliability.

But the early PHP MV model’s recoil spring guide was not optimal, which caused friction at the point of contact between the recoil spring and the recoil spring tunnel in the frame. Because of that, unequal resistance was created when pulling the slide to its rearmost position. Later, adding a front recoil spring plug solved the problem.

Advertisement — Continue Reading Below

The early PHP MV featured a loaded-chamber indicator in the form of a metal rod that protruded from the left side of the slide when a round was loaded in the chamber. This design was later replaced with an external extractor that also served as a loaded-chamber indicator.

PHP MV Details

The slide, frame and smaller operating parts were milled out of solid blocks of Cr-Ni-Mo austenitic stainless steel—an expensive procedure that was later dropped for more affordable investment casting. The magazine catch was placed on the left side of the grip frame, and the pistol used double-stack, 15-round magazines. Earlier magazines were troublesome, but later magazines were made with better materials and featured redesigned followers for better reliability.

The trigger was a traditional DA/SA design. A manual decocking lever was positioned on the left side of the frame along with a slide stop that automatically caught the slide, locking it fully open, after the last round in the magazine was fired.

Advertisement — Continue Reading Below

Four models of the PHP MV were produced: the Standard with either a 4.5- or 5-inch barrel, the Target with an extended 6.5-inch barrel, and the Compact with a 4-inch barrel. Most of the production was devoted to the Standard and Compact models. The first batch of pistols had wooden grips, but these were later replaced with synthetic panels. The pistols also had fixed sights consisting of a front blade and a rear notch. The width of the base of the front sight was identical to the width of the dovetail slot on the slide.

Because of hasty wartime production, parts of the PHP MV were prone to breaking, especially the first lots, which were of poor quality. PHP MV production then ceased in 1994; only about 5,000 of the pistols were made.

HS 95 Redesign

The PHP MV performed badly in tests and assessments with actual shooters. This spurred development of a new pistol in June of 1995. It was given the “HS” prefix for “Hrvatski Samokres,” or “Croatian Pistol.”

Advertisement — Continue Reading Below

The HS 95 pistol, like the former model PHP, was a 9mm, but that’s where the similarities ended—it was a radical redesign. Instead of the Walther style, the HS 95 used a modified Browning locking system. The HS 95’s appearance was also sleeker than its predecessor. It has been compared to some Sig Sauer pistols and the Zastava CZ 99, but no patent infringements were cited. Rather, IM-Metal was implementing a proven pistol design.

Cost-effective investment casting highlighted the HS 95’s production, although the barrels were still produced with traditional cold-hammer forging. The chunky slide was fully closed and had a reinforced ejection port to hedge against material breakage. Eventually, the beefier ejection port was considered redundant and subsequently deleted.

Other HS 95 Upgrades

Other upgrades include a frame-mounted slide release/decocking lever, an automatic firing pin safety and an enlarged triggerguard to accommodate heavy gloves. Also, the new pistol was fully ambidextrous—the magazine release and slide release/decocker levers were present on both sides. However, designers kept the disassembly lever on the left side of the frame to accommodate right-handed shooters. The pistol also had improved ergonomics, synthetic grip panels and updated magazines with new floorplates.

Still, the Browning-style tilting-barrel system was the most distinguishing aspect of the new gun’s barrel-to-slide interface, which actually proved easier to make while maintaining tight tolerances. Extensive testing also showed that the DA/SA trigger group, along with the decocking lever and automatic firing pin safety, promoted safe handling.

An earlier model of the HS 95 had a rear sight that could be adjusted for elevation from inside of the slide, but that was replaced with a classic dovetailed rear sight—a better choice for combat shooting. The HS 95’s hefty steel frame made it one of the heaviest pistols of its class. Nevertheless, several Croatian police and military units soon embraced it.

Polymer-Framed HS 2000

Designers at IM-Metal joined manufacturers worldwide in pursuing plastics to make lightweight frames for pistols. The company developed its first polymer-framed handgun prototypes in 1998 with help from the Faculty of Mechanical Engineering and Naval Architecture in Zagreb, the Croatian Institute of Technology and small-arms experts from the Croatian Ministry of Defense.

The new model, officially named the HS 2000, utilized a frame made of Ultramid PA 66 material from BASF. This polyamide has a very robust chemical composition; it’s extremely durable and very “thermostable.” That means it can withstand sustained temperatures of 180 to 190 degrees. In addition, it can withstand short-term exposure up to 230 degrees. Early models had all-plastic slide rails but a steel locking block in front. Later, a redesign merged the front rails into a major part of the steel locking block. That meant only the rear slide rails were still plastic; later tests showed those parts weren’t as vulnerable as their counterparts up front.

Meanwhile, designers also improved the grip frame with ample checkering on the front- and backstraps—a major consideration for shooters with wet or sweaty hands. The designers also avoided excessive buttons and levers, which eased both production in the factory and handling for the shooter. To that end, the pistol only had a slide release, a magazine release and a disassembly lever. The gun looked a lot like a Glock 17 externally, but internally the HS 2000 was another story.

HS 2000 Trigger & Slide

The HS 2000 featured a factory-installed single-action trigger mechanism. Squeeze the trigger and the falling sear slides down and disengages the firing pin. That’s because it’s engaged directly with the striker firing pin. Also, the pistol uses a grip safety similar to the one on a Model 1911. So, if the shooter doesn’t hold the gun correctly to disengage the safety, it won’t shoot.

The HS 2000’s trigger mechanism was factory adjustable from 3.3 pounds through 13.22 pounds while staying safely operational. Competition models also came with tuned triggers and a lighter pull weight of only 2.64 pounds, but an accompanying disclaimer warned not to use those models for duty use. It’s also worthy noting that the new design of the trigger and frame made for a short trigger reach for those with smaller hands.

One similarity the HS 2000 had with its predecessors was that they all accepted the same 15-round, stainless steel magazines, although buyers in Canada and the U.S. were limited to only 10-round magazines.

The HS 2000’s slide, like the one on the HS 95, was formed from investment castings to lower manufacturing costs. A two-step layout design trimmed the overall weight of moving parts but also kept the slide’s structural reliability. The front part of the slide was thickened to avert stress where the slide met the recoil spring. Designers sought to thwart stovepipe jams or other failure-to-eject issues by including a widened and lowered ejection port. The barrels were made from fine bar stock provided by the Austrian firm Böhler-Uddeholm.

HS Produkt

Also, in 1998, Vuković and Zabcic used the HS 2000 as a springboard to create a larger and more modern company. They moved from Ozalj to neighboring Karlovac, where they formed HS Produkt. Modern computerized equipment helped reduce the time it took to produce the first acceptable HS 2000 pistols for mass production.

Entering The U.S. As The Springfield XD

HS Produkt signed its first export contract in 2000 with Intrac Arms International of Knoxville, Tennessee, which brought 10,000 of the Croatian pistols to the U.S. That company, however, had a limited network of sellers. But in 2001, Dubi Pikielny, an agent for Springfield Armory, visited HS Produkt to express interest in distributing the HS 2000 in the states.

Another year passed with thorough testing, and Springfield Armory eventually won a contract to market variations of the HS 2000 in the U.S., but with different names. Enter the Springfield XD (Xtreme Duty) family of striker-fired, polymer-framed, semi-automatic pistols. This line has become so popular that the company now markets several styles and variants, including the Springfield XD Mod.2, Springfield XDM and Springfield XD-S with various barrel lengths in 9mm, .40 S&W and .45 ACP.

In a relatively short period of time, Croatia’s first pistols have become modern, combat-worthy firearms that can appeal to all shooters, even those here in America.

Croatian Pistol Specs

| Manufacturer | PHP MV Standard | HS 95 | HS Produkt HS 2000 |

|---|---|---|---|

| Caliber | 9mm | 9mm | 9mm |

| Barrel | 5 inches | 4 inches | 4 inches |

| OA Length | 8 inches | 7 inches | 7.08 inches |

| Weight | 35 ounces (empty) | 46 ounces (empty) | 26.88 ounces (empty) |

| Grips | Wood or synthetic | Synthetic | Polymer |

| Sights | Front blade, notch rear | Front blade, notch rear | Front blade, adjustable rear |

| Action | DA/SA | DA/SA | Striker-fired |

| Finish | Blued | Blued | Matte black |

| Capacity | 15+1 | 15+1 | 15+1 |