DSA SA58 Para Tactical Carbine .308 Details

The DS Arms SA58 Para Tactical Carbine’s upper receiver is machined to original Steyr blueprints from a 4140 steel forging. It uses modern CNC machinery, and heat treated to a hardness of Rockwell C 30-40. Lower receivers are of 7075 T6 aircraft-grade aluminum alloy forgings.

The fluted medium contour 16.25-inch barrel is a Badger unit, which is broach cut, hand-lapped chrome-moly with a 1:10-inch twist and four grooves. These barrels are double stress relieve and receive an 11-degree crown. An A2-style flash hider is threaded onto the muzzle. Options for integral muzzle brakes are available. The remaining parts on the rifle are heat-treated investment castings. DSA’s rifles and carbines are backed by their lifetime warranty.

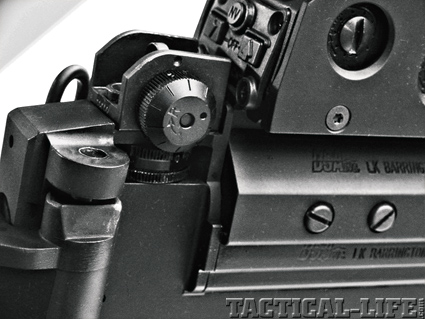

I ordered the Para SA58 Tactical Carbine with the short handguards and gas system. I also requested the Extreme Duty Scope Mount. DSA is planning two new sight options in production. The first will be The “Hampton A2 Lower,” an AR-15 A2-style adjustable windage and elevation drum on the rear of the FAL lower, which will sit flush just like the old Para sight but will be identical to an AR15 A2 rear. The other will be a Picatinny lower with no iron sights. Instead, a Picatinny gas block for use with a front flip-up sight, and a Picatinny rear for a flip-up rear sight. Any flip-up BUIS-type sight mountable on a Picatinny rail will mate with this configuration. This will leave almost any scope option available, in place of or in addition to the aforementioned flip-up sights.

Advertisement — Continue Reading Below

Sights

The front sight on my sample carbine was an elevation adjustable protected post. Overall length is 37.75 inches with a 19-inch sight radius, with a weight of only 8.4 pounds. There are sling swivels mounted at the front of the handguards and on the aft of the lower receiver.

Trigger

The good folks at DSA surprised me by doing their combat trigger job on my sample carbine. This trigger is incredible. It has a little bit of take-up but is remarkably smooth and light. It breaks crisply at 3.5 pounds on my RCBS trigger scale. If you have the budget to add this option, I highly recommend it.

Frame

The fit, finish and machine work on my sample carbine were excellent throughout. However, there were some obvious machine marks on one of the lightening cuts on the right side of the receiver. My test rifle came with a DuraCoat finish.

Advertisement — Continue Reading Below

Pistol Grip

Some other differences that I noticed with the Para are the SAW pistol grip, which has a trap door in its recess for storage, a magazine release in the style of the original FALs, and sand cuts on the bolt carrier. The sand cuts were a modification that the British made to their L1A1 version of the FAL. This channeled sand and grit out of the mechanism for reliable functioning in harsh climates. This only adds to the legendary reliability of the FAL platform and is standard with the Para models.

Safety

My carbine also was equipped with DSA’s extended L1A1-style thumb safety, which you can’t miss when wiping it off. I usually hook my thumb below thumb safeties. You really need to rest the thumb atop this extended safety to avoid inadvertently engaging it. A simple training issue that I will have to address.

The Para Tactical Carbine’s folding stock is very simple in its operation. One merely pushes the stock downward against its internal spring to unlock the mechanism. It can then be swung open or folded. The folding feature cuts the length of the gun down by almost 10 inches.

Advertisement — Continue Reading Below

Field stripping for cleaning was barely more complicated than a standard FAL. It consisted of breaking the upper and lower receivers open, then pushing the recoil spring assembly back toward the breech about a quarter of an inch and then down. The spring and guide rod assembly can then be simply extracted, and the bolt and carrier slide right out. The bolt is then easily separated from its carrier.

This simple procedure gives access to the receivers, bolt and carrier, breech, and bore for cleaning.

After several range sessions, you might want to clean the gas piston/tube. All of these procedures can be easily accomplished without any tools.

Advertisement — Continue Reading Below

.223 vs .308 Caliber

The .223 may have been the dominant caliber for patrol rifles for decades, but it has never been the fight-stopper the .308 has proven to be. Its “dominance” has more to do with its lack of over-penetration problems. However, this problem no longer hinders the mighty .308 with recent developments in police and tactical ammunition. For example, Hornady’s TAP (Tactical Application Police) ammunition in the 110-grain version penetrates an average of less than 10 inches in ballistic gelatin. It generates much less recoil than the standard load. Another is Federal’s TRU (Tactical Rifle Urban) ammunition.

With that problem solved, why stick with a round, with returning reports of dismal performance from the war in Iraq and Afghanistan, when you can have the proven effectiveness of the “big kid” on the block? Very innovative and effective ammunition designs have squeezed out every last ounce of efficiency, to be sure, but a .223 simply won’t ever have the energy of a .308. And those design “tweaks” can also be applied to this more powerful round.

FAL System

The gas piston operating system of the FAL is a long-proven design, which is more reliable than that of the AR15, AR10, and M16. It has fewer moving parts, will continue working longer when dirty, and is easier to maintain.

Advertisement — Continue Reading Below

This last feature is a big reason I’ve gone to the FAL. The FAL has three major components that need to be cleaned, for the most part, for efficient functioning: the bolt, its carrier, and the bore itself. This process is incredibly simple. Depress the frame locking lever on the side of the receiver, and break the upper and lower receivers open, shotgun style. Slide the bolt and carrier out to the rear; separate the bolt and carrier by compressing its firing pin and lifting it out. For the most part, that’s it. The bolt and carrier can then be easily cleaned, as well as the bore. The top cover simply slides off of the receiver once the gun is “cracked open,” making for unrestricted access to the inside.

Cleaning

Occasionally, you should clean the gas tube and piston, but this is not always necessary with every cleaning. Even so, this process consists of twisting the gas plug off, and using a .45 caliber brush to clean the tube, and a standard nylon brush to clean the piston. You’re done. All of the crevices and recesses in the FAL are large and much more accessible. I now spend less than a fourth of the time cleaning my FAL than I did with my AR15.

Advertisement — Continue Reading Below

SA58 Para Tactical Carbine .308 is the ultimate police carbine. (shown here with Ka-Bar USMC Fighting Knife)

Note the sand cuts in the bolt carrier to channel grit out of the mechanism. Tool marks on the lightening cut of the mag well are the only flaw in machining.

Range Time with the DSA SA58 Carbine

At the range, I set the carbine up benched on a sandbag at 100 yards. I began to sight the weapon in with the iron sights by patterning 3-shot groups, simultaneously testing for proper gas setting. The gas setting is easily accomplished in a matter of minutes by putting an empty magazine in place, then dropping one round into the ejection port and chambering it. Then, open the gas regulator one click at a time by simply turning the regulator, which looks and works like a knob. Continue opening the regulator one more click with each round fired (which amounts to bleeding more and more gas away from the system) until the bolt hold-open mechanism fails. Then close the regulator back down a couple of clicks, and you’re ready. An adjustable gas system allows fine-tuning to produce the least possible amount of battering on the mechanism and shooter.

New lower receiver is machined for “Hampton” A-2 AR-15 A2-style adjustable windage and elevation drum sight. Picatinny rail system on the rear of the receiver and gas block is also now available.

My initial testing was with Portuguese Military surplus ammunition, as I have plenty on hand, and it was among the most accurate loads through my personal DSA SA58 standard Tactical Carbine. The first 3 rounds out of the cold barrel went into 2.5 inches—not bad at all. Through the course of the day, I found the iron sights to be already zeroed at 100 yards with a small variance depending on which ammo was used. Had I needed to adjust the sights, this would have been effortlessly accomplished by hand. Turn clicks of the “Hampton” style A2 rear sight for both windage and elevation. If elevation adjustment is required of the front post, a small two-pronged tool is needed.

Accurate fire was made easier by the exceptional trigger. Once satisfied the sights were putting the bullets where I was sighting, I mounted an L-3 EOTech 550AA HWS on the Extreme Duty Scope Mount.

Optics

Up until this point, I’ve been a bit resistant to reflex-type scopes. I’n reluctant to trust anything but iron sights to hold up under abuse, but I must say that the L-3 EOTech makes it easier to shoot accurately.

This is because the red dot covers about 1-inch of the target at 100 yards. It can be centered on the target rather than aligning the front post to cut the center in half. All of the “eyeballing” of this process is taken out of the equation, which makes for a much more consistent aligning of the sight. Its other obvious advantage is in low light. If you can see your target, you’ll have no trouble seeing the dot. A convenient feature of the 550AA is the fact it’s powered by standard AA alkaline batteries.

Groupings

My best groups came from the 130-grain CorBon/Glaser Safety Slug at 1.19 inches. Federal’s 165-grain TRU printed a group of 1.68 inches, and I recently attended a ballistic workshop, where the Federal TRU showed impressive results with sufficient penetration and very high weight retention through various media, including windshield glass. CorBon’s 168-grain DPX yielded a pattern of 1.88 inches.

Velocities were measured with a Beta Chrony chronograph. Hornady’s 110-grain TAP turned in the highest velocities from the DSA’s 16.25-inch barrel with an average of 2890 feet per second (fps). This has grown to be one of my favorite duty loads with an average penetration depth in ballistic gelatin of just under 10 inches. Despite its high velocity, it generates significantly less felt recoil due to light bullet weight.

Impressions

The Para was quite pleasant to shoot. I did not experience any increase in felt recoil from that of my SA58, which has a rubber butt pad on the stock. Some FAL enthusiasts have theorized this is because the Para’s spring system is directly in line with the travel of the bolt carrier rather than canted downward in the stock. But I also noticed that the Para is front-heavy, due to the light alloy skeletonized buttstock, which probably contributes to less muzzle rise. The metal, grooved buttstock does tend to chafe the skin a bit with extended shooting sessions, but I fired over 400 rounds in an afternoon. The Para Tactical Carbine functioned flawlessly with all ammo, other than those deliberately induced during gas setting.

After running my tests, I enjoyed shooting some multiple target drills using barricades to simulate cover, shooting, and moving from the 50- to 25-yard lines. Hold the DSA Para tight during rapid fire, after all, this is a .308!

I also shot one of our state’s police rifle qualification courses and was easily able to shoot a score of 90% on a course designed for the soft-shooting AR15.

Final Editor Notes

I’ve had the standard DSA SA58 carbine and carried it on duty for a couple of years. I’ve had nothing but positive experiences with it, and never looked back. It’s the best balance of power and handiness that I knew of. However, the Para SA58 Tactical Carbine is even better.