https://www.youtube.com/watch?v=qhXDzpgmh6o&feature=youtu.be

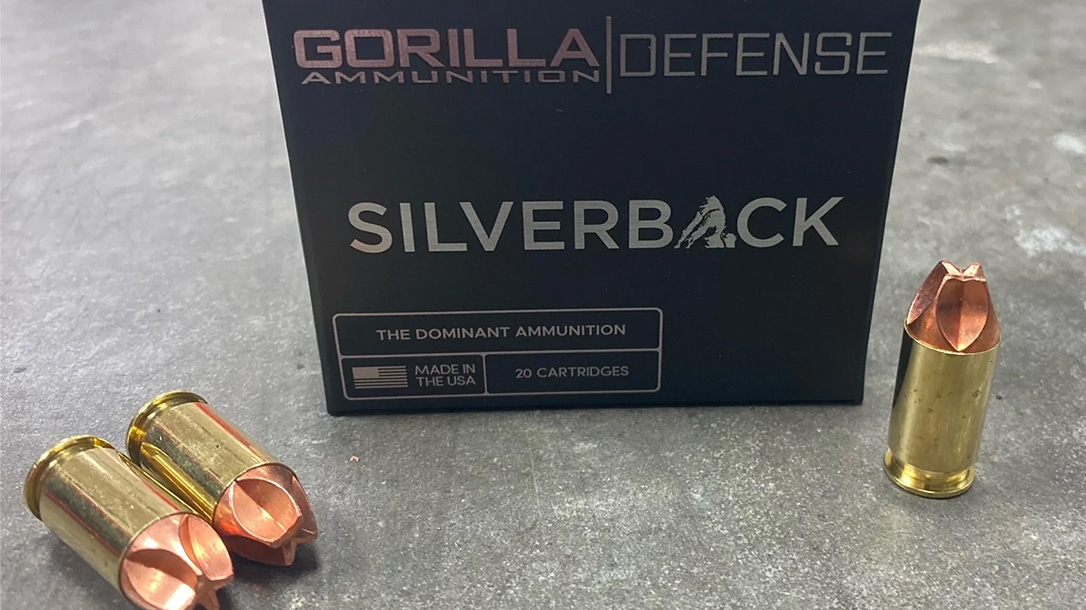

Gorilla Ammunition has introduced its new Silverback product line, featuring projectiles that are CNC-machined from solid copper.

Starting loads will be available in .380 ACP, 9mm and .45 ACP for handguns as well as the 300 Blackout for rifles. These technologically advanced projectiles create amazing temporary and permanent wound cavities with controlled expansion to optimum depths.

Advertisement — Continue Reading Below

These lead-free, CNC-lathe-turned, copper projectiles are expertly engineered and fine-tuned for maximum expansion with penetration depths dictated by user requirements.

Gorilla Ammunition’s proprietary heat treating and CNC machining process provides the unique ability to tweak projectile performance in soft tissue. “This technology is groundbreaking for the ammunition industry and self-defense ammunition consumers,” said Lanse Padgett, Gorilla’s co-founder and CEO.

- RELATED STORY: Gorilla Ammunition .300 BLK Subsonic 208gr Hornady A-MAX

One Silverback load that is already being considered a game-changer for the industry is the new 300 Blackout, as the new subsonic Silverback cartridge expands sufficiently for optimum use with a suppressor.

Advertisement — Continue Reading Below

For more information on the Silverback line, visit gorillaammo.com.