When Alex Zimmerman brought his newest model, the Guncrafter Industries Model 3, to market, I knew I wanted to write about it, as I’ve tested two of his pistols in the past. Frankly, this was also what I had been waiting for, as, years ago, I had basically abandoned the full-length 1911s I’d formerly preferred in favor of the Commander-length guns (or any of the models in the 4-inch-barreled range). I find their balance more to my liking, and they’re quicker out of the holster, faster on target and more easily concealed. And truth be told, the only place you’re going to realize the added accuracy from a full-length gun is from a benched, slow-fire test, if at all, or on a chronograph.

To fully disclose my proclivities, in my personal meeting with Zimmerman, coupled with having tested two of his pistols, I found the man to be impressive and interesting, and I could see the superiority of his pistolsmithing.

When I say interesting, what I mean is that Alex is a native of Denmark and, as a young man, he developed a strong interest in competitive shooting. Over the next 10 years, he began traveling to the U.S. to shoot in matches, such as the Steel Challenge, Second Chance, American Handgunner World Shoot-Off, and others; he has won the National IDPA Stock Revolver Championships seven times consecutively. Out of necessity, he began doing his own custom pistolsmithing and started his own firearms business, supporting himself as he endeavored to complete his B.A. in mechanical engineering.

Advertisement — Continue Reading Below

During one of his sojourns to the U.S., he met Bill Wilson, who offered him a job. He spent the next eight years as the director of research and development at Wilson Combat, and he interacted with some of the best pistolsmiths in the country.

Whereas he’d had a dream of creating a practical .50 caliber pistol on the 1911 platform while studying for his engineering degree in Denmark, the very strict gun ownership laws in Europe made the project pointless. But he never forgot his idea for this very serious defensive 1911 pistol.

In 2002 it was time to pursue his dream, so he resigned from Wilson and founded Guncrafter Industries. He spent two years developing the .50 GI and unveiled it in 2004, bringing the Model 2 to market six months later.

Advertisement — Continue Reading Below

Gun Details

As already touched upon, the Model 3, released in 2010, is a Commander-length 1911, albeit chambered in the larger .50 GI round. One quick look reveals that the pistol has an outstanding fit and finish, with a Bobtail frame and a matte-black exterior. Those unfamiliar with these .50 GI pistols might be surprised upon hefting them, as the their outside dimensions are the same as those of traditional 1911s. And at just 35 ounces, it is light as well! The bobbed frame is machined from a 4140 chrome-moly forging and treated to a carry bevel. Other than its bobbed contours, there’s not a lot different about the dimensions of the frame other than the fact that the magazine well opening is wider, the feed ramp is huge and the bevel on the well is narrower to accommodate the larger canal. Custom features include 20-lpi checkering on the frontstrap and what appears to be 30-lpi checkering on the mainspring housing, while the bobbed contour is smooth. An undercut eliminates the excess metal from under the triggerguard, which, in conjunction with the flawlessly blended, memory-bump-equipped beavertail grip safety, facilitates a high hold. The single-sided, modestly extended thumb safety bears serrations on its pad, and the smooth-contoured slide lock, machined from bar stock, has also been slightly extended. The mag release is slightly raised and serrated.

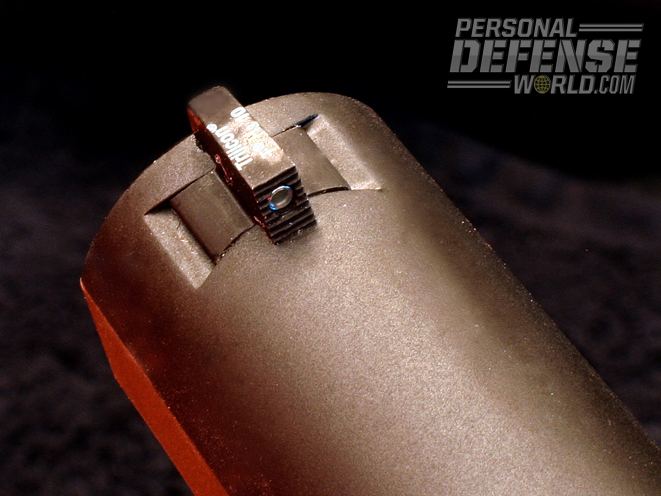

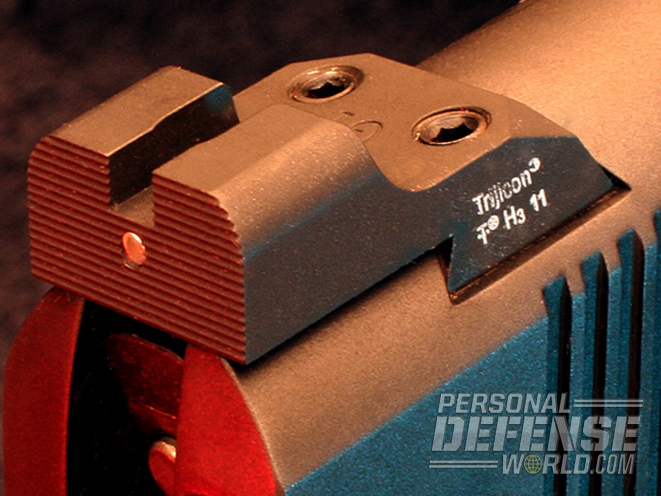

Also machined from a 4140 chrome-moly forging, the slide features deeply cut rear cocking serrations, Guncrafter designed night sights and an ejection port that is lowered and flared. The traditional internal extractor, machined from hardened chrome-moly bar stock, is blended smoothly at the back of the slide. The starboard flank of the slide is roll-marked “Model No. 3.”

Advertisement — Continue Reading Below

The heavy, match-grade, 4.25-inch barrel is cut from a rifle-quality 416R stainless steel forging. The barrel features an 11-degree crown and 1-in-16-inch, right-hand twist rifling. It’s also a bull barrel, meaning it has a full 0.75-inch diameter at the chamber and muzzle and mates directly to the slide, dispensing with the traditional 1911 bushing. The chamber hood is marked “.50 GI.”

Accommodating the extra energy of the big .50 GI cartridge, the recoil spring is a heavy-duty, flat-wire unit rated at 25 pounds; a solid steel guide rod is employed.

The fit between the slide and frame is exceptionally tight, with no slop whatsoever between the two, even with the slide retracted. I could not budge the barrel up or down while in battery.

Advertisement — Continue Reading Below

An adjustable aluminum trigger “in the white” with a finely serrated face trips the sear from under the hammer hooks. The hammer, sear and disconnector are high-grade tool steel. The slide stop, extractor and ejector are hardened chrome-moly, all machined from bar stock. The hammer is skeletonized and features a rounded spur.

My test pistol had a black Parkerized finished, but hard chrome, Ionbond, Melonite and Cerakote are available. The Model 3 also comes with radical “Shredder” grip panels made by Larry Davidson. Alumagrips also offers gray-green, aircraft-grade-aluminum, machine-checkered grips bearing the GI logo. A .45 ACP conversion, which consists of a barrel and magazines, is also available.

Range Time

Advertisement — Continue Reading Below

With the Model 3 and a bevy of ammunition supplied by GI, I headed for the range to test the gun’s performance. The ammo supplied was GI’s copper hollow point (CHP) ammo in 185-, 230- and 275-grain bullet weights, as well as the company’s 300-grain jacketed flat point (JFP). After setting up targets, I settled in at a distance of 25 yards, where I benched the pistol to fire five-round groups to test its inherent accuracy.

Shooting in such a manner, the best accuracy of the afternoon came, ironically, from the heaviest round (the 300-grain JFP), which created a group measuring 1.13 inches center to center. (More likely, this was the best I could get my act together as the shooter). The 275-grain CHP turned in a pattern of 2 inches, and this was followed by the 230- and 185-grain CHPs at 3.88 and 3.63 inches, respectively. Velocities ranged from only 744 fps from the 300-grain JFP to a whopping 1,160 fps from the 185-grain CHP!

Advertisement — Continue Reading Below

The gun handled beautifully. It is very ergonomic in the hand due to the custom touches that let you obtain a high grip, and the pistol was quite comfortable to shoot. Despite the big, scary caliber, shooters will be pleasantly surprised to find that Alex achieved what he set out to do—a practical defensive pistol with a .50-caliber round. There is no punishing recoil with slow recovery times before the sights settle back on target. The 185-grain CHP load recoils about as sharply as a .45 ACP +P and less than a 10mm. This is due to the large caliber and low working pressure of the .50 GI cartridge. The heavier loads, like the 300-grain JFP, give about the same impulse as a 230-grain .45 ACP. This sort of handling is entirely appropriate for a combat pistol.

After testing for velocities and accuracy, I had some fun ringing steel silhouettes at 15 yards, and the 300-grain FMJs literally slapped the steel targets to the pavement. Throughout the course of the afternoon, I never experienced a single failure to feed or even choppy cycling.

If you’re familiar with the 1911, this gun feels exactly like (and shoots like) the 1911 with its unsurpassed ergonomics. All its outside dimensions remain identical to the 1911, and even the weight is the same. Holsters for standard 1911s will fit the Model 3. The excellent trigger gives a crisp break at 4.5 pounds after about 0.06 inches of play, with no overtravel. A superior trigger always makes a pistol easier to shoot accurately, and that was the case here.

The 20-lpi checkering on the frontstrap and mainspring housing, coupled with the aggressively textured and deeply relieved G10 Shredder grips ensured a rock-solid grasp on the gun. This, combined with the undercut triggerguard and upswept beavertail, contributes to control and a reduction of muzzle flip, as does the front-heavy, recoil-dampening bull barrel. If a shooter finds these grips too thick and/or abrasive, the aforementioned GI Alumagrips may be used. These are comfortable while providing plenty of traction.

The beavertail disengaged consistently, even though I take a high hold on the thumb safety. The Heinie sights afforded a pronounced, wide front blade and a large, squared rear notch, making them fast and easy to pick up with the eyes. I prefer the Straight Eight night sight system, as it is very fast in low light.

Reloads were smooth, given the extra metal removed from the magazine well, and the GI mags, with their thick, heavy-gauge stainless steel construction, felt noticeably more solid compared to standard .45 ACP magazines.

Final Notes

As I mentioned, I had tested two other models from Guncrafter Industries before and had high expectations, and the Model 3 didn’t disappoint. It was a comfortable pistol to shoot, and the craftsmanship was stellar. Furthermore, it ran smoothly without exception. The .50 GI cartridge adds another dimension to the gun, boosting its effectiveness as a defensive weapon while making very little compromises.

The 185-grain CHP gives close to 600 foot-pounds of energy, and the 230-grain CHP gives deeper penetration while still expanding to a 1-inch diameter—an outstanding defensive load!

The GI solid CHP bullets are individually turned on a high-precision CNC lathe, resulting in excellent accuracy and reliable expansion to a full inch with perfect symmetry; the bullet retains its full weight since it is one solid piece of copper. GI has guaranteed customers to keep literally truckloads of ammo on hand, and the JHPs and JFPs are only about $20 per box of 20, so they aren’t ridiculous. The CHPs are about twice that.

Guncrafter Industries’ custom-grade pistols cannot be compared to those mass produced on an assembly line, justifying their higher price tags. When you buy a GI, you’re getting an heirloom-quality firearm.

For more information, visit http://www.guncrafterindustries.com or call 479-665-2466.