The roller-delayed-blowback family of Heckler & Koch (HK) weapons has always held a certain mystique for me. Heralding back to the heydays of the 1970s and 1980s when U.S. shooters had access to a wide selection of foreign-made semi-automatic small arms, these classic firearms always caught my eye on the rifle racks at the local gun shop. However, as a young teenager with little discretionary income, I was not able to purchase one before the unfortunate (and utterly misguided) restriction on their importation in the late 1980s.

- RELATED: Top 20 Next-Gen Combat Rifles

- RELATED: Top 20 Next-Gen Piston-Driven ARs

Fast-forward to today. While we are awash in just about every variant imaginable of the ever-popular AR-pattern rifle, shooters with slightly more idiosyncratic tastes such as myself must dig a little deeper to locate interesting alternatives. Needless to say, my interest was piqued when I received a press release from a new company indicating it planned to produce a group of U.S.-made firearms based on the HK roller-delayed-blowback family of weapons. That company is Moore Advanced Dynamics (MAD), and its goal is to deliver both original and modernized variants of these weapons with a custom-grade attention to detail achieved through handwork and hand fitting. But, before we dig into the details of the new company and its products, it may be helpful to first lay out the details of what makes these roller-delayed-blowback weapons so interesting.

Advertisement — Continue Reading Below

Full Circle

The HK series of roller-locking small arms should be familiar to students of military rifles, with the G3 being one of the most widely produced 7.62x51mm rifles in the world. Stemming from a weapon dubbed the StG 45 and developed in Germany in the waning years of World War II, the design had a circuitous early life that carried it through post-war France, then Spain (as the CETME) and then back to its homeland in the Cold War-era West Germany. It was there in the late 1950s that it became the G3, produced under the banner of Heckler & Koch.

The design was revolutionary in every sense of the word. While taking advantage of modern manufacturing techniques such as extensive use of stamped steel and plastics, what truly set the design apart was its operating system. While comparable designs employed some variant of a gas system (where gas is tapped off the bore to unlock a rotating or titling bolt and then cycle the action), the G3 employed what may be best described as a delayed-blowback system. Firing from a closed bolt, the G3 employed a non-rotating bolt head that was instead locked into place with dual rollers located at the 3 and 9 o’clock positions on the bolt head. These two rollers locked into recesses located inside a steel trunnion inside the stamped steel receiver.

Advertisement — Continue Reading Below

When a round was touched off, the forced required to push the rollers back into their recesses within the bolt would keep the action closed long enough for chamber pressures to drop to safe levels. When this happened, the case would be pulled straight back and ejected, with the recoil spring assembly then driving the bolt and bolt carrier forward to strip a new round from the magazine. While it may seem that the massive chamber pressure and recoil force created by the 7.62x51mm cartridge would overwhelm a system like this, it proved to be a solid and reliable design. The result was a truly unique operating system that offered several advantages over the somewhat more complex gas-operated systems.

As an interesting side note, one design element added to the design was the addition of longitudinal flutes within the chamber. Testing of the roller-delayed-blowback design revealed a tendency for the bolt to rip off the heads of fired cases in the chamber. This was likely due to the lack of rotation of the case as would happen with a rotating bolt system, which helps break the fire-formed case loose from the chamber. Short of lubricating the cases (which would be problematic and impractical in a military small arm), the designers had to come up with a solution. The answer was the addition of the flutes within the chamber that allowed gases to flow around the fired case and help it reliably and consistently release from the chamber.

The G3 was an immediate success, being adopted by the West German military as well as many other militaries around the world. And, due to popular demand and HK’s interest in expanding into other markets, the company developed variants of the design in 5.56x45mm (as the HK33) and also 9x19mm (as the MP5). The result was an entire family of small arms that combined simplicity of operation with rugged reliability. It was these designs that became the basis of the civilian-legal semi-automatic guns I had admired on the racks at the gun shop—the HK91 (7.62x51mm), the HK93 (5.56x45mm) and the HK94 (9x19mm).

Advertisement — Continue Reading Below

A New Beginning

But what is a fan of this design to do today, with the originals not only restricted from importation but also no longer produced by HK? Enter Moore Advanced Dynamics, a domestic manufacturer bringing a custom shop approach to the production of these classic weapon systems—as well as a fresh approach to the designs. After I spotted the press release from the company, I called and had a chance to speak to Gary Jessup, general manager of the company, at length about not only the MAD guns, but also the people behind the company.

Advertisement — Continue Reading Below

“The founding group here at the company is made up of four people. They are James Eric Moore, the owner; Chris Alexander, master builder and R&D coordinator; Mark Jessup, finish and quality manager (as well as product development); and me, as general manager,” Gary explained. The result is a small but agile company dedicated to one simple goal: making the best guns possible. “We have four guys all looking at the same products, but from four different perspectives. When we all agree on a solution, it is usually the best path forward,” he said. He then went on to explain to me that each and every gun is hand built in small numbers to maintain top-notch quality control.

My next question for Gary was how these guns would compare against original guns from the ’70s and ’80s. “We know the design, and we also know how to take it to the next level. I have been shooting these guns for 20 years. Give me a pile of parts and a blindfold and I can put any of them together. Mark and Chris have surpassed me, and Eric brings both a ‘big picture’ and an exacting detail perspective to the entire system.” Gary went on to explain that the MAD guns are built to the original standards, but with even tighter tolerances. “That is where all the handwork and attention sets our guns apart,” he said with a hint of pride in his voice.

The result is a line of guns made up of 7.62x51mm (MAD91), 5.56x45mm (MAD33) and 9x19mm (MAD9) series weapons. As with most domestically produced guns of these types, the MAD guns feature a combination of U.S.- and foreign-made parts. In the case of these guns, all the non-U.S. parts are original German HK parts sourced from Adam Weber at hkparts.net. “Adam is a wealth of information on these types of guns, and has been instrumental in this entire project,” Gary said.

Advertisement — Continue Reading Below

But, it is important to remember that the guns are more than simply the sum of their parts, with the company’s exquisite attention to detail making sure it all comes together correctly. “We are not simply a parts assembler. We are building these guns ‘right’ from the ground up. On each gun, we match up the bolt carrier assembly, trunnion and barrel for fit and keep them together through the whole process. And that is just one part of the process,” he continued. “I could tell you where we acquired every part for each gun, but that doesn’t mean you are going to be able to put them together in your garage. We’ve worked hard to get these to the quality level we want to give to the customer, and I think it shows in the end result.”

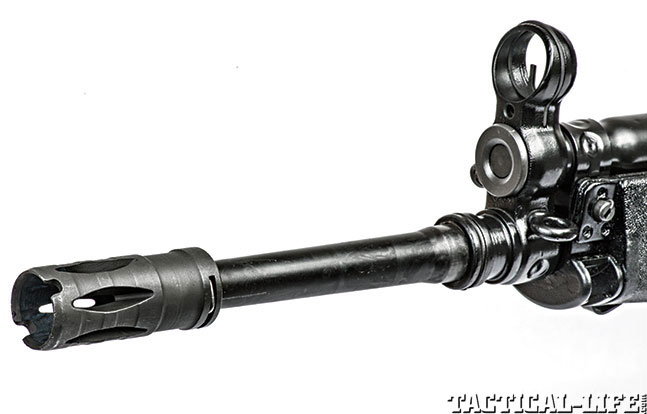

As the conversation continued, I asked him in particular about the MAD33 rifle and its sibling, the MAD33K. For the purist, the MAD33 is a dream come true, being a straightforward semi-automatic recreation of the HK33. For those looking for something a little different, the MAD33K is the “Kurz” version that features a 12.69-inch barrel with a long, permanently attached muzzle device to bring the barrel to a non-NFA 16 inches. Both fixed and collapsible stocks are available, as is a tri-rail forend. A strip of Picatinny rail is welded to the top of the MAD33K’s receiver for mounting optics.

One other really interesting thing Moore Advanced Dynamics has developed is an AR magazine adapter system for the MAD33 5.56mm. This interesting option (standard/removable on MAD33AR and MAD33KAR rifles, or available for your own HK33/HK93-style rifle) allows you to use standard AR-15-pattern magazines (the company recommends the use of Magpul PMAGs, but the system is designed to work with any modern polymer or standard GI samples). “What we are trying to do with this and the optional rail system is give AR fans a new take on the classic HK system. They can bring their AR gear to this gun, and it is ready to go,” Gary said.

Advertisement — Continue Reading Below

Range Time

I recently had an opportunity to try out the MAD33 series of rifles for myself. I received a standard MAD33 rifle in 5.56mm NATO, and I was immediately struck by its fit and finish. All of the welds on the gun were clean, and the Cerakote finish on the metal was a rich, deep black (although other colors are also available). I also noted that it (like all MAD guns) featured the original-style paddle magazine release—a nice bit of attention to detail. A fixed stock and polymer lower assembly rounded out the package. The sample MAD33 I received did have one upgrade over a standard gun—Gary had cut some angled cooling vents into the handguard. Apart from that, it was practically a stock HK93.

All MAD33 variants feature 1-in-7-inch-twist barrels, so I selected a range of both light and heavier bullets for testing the MAD33 standard rifle. As I did not have a claw mount available, I elected to test the rifle with open sights at 100 yards. Once I had my ammunition selected, I headed out to the range with the gun and the ammo. I settled in on the bench and began running the rifle through its paces. The rifle’s accuracy—particularly considering I was using open sights—was outstanding. The tightest group, achieved with the lightest bullet weight of 45 grains, was a 1.25-inch group with the Winchester load. The other two loads came in within the 1- to 2-inch range, which I consider to be outstanding for an iron-sighted gun at this distance.

When it comes to delivering a top-quality 5.56mm rifle that has been hard to acquire for about a quarter century now, Moore Advanced Dynamics has definitely delivered with its MAD33 series. From the classic standard MAD33 to the short MAD33K to the MAD33KAR ready to accept AR magazines, there is definitely a rifle out there for you. For those who want something a little different than a cookie-cutter AR, the MAD guns deserve a very close look.

For more information, visit madkc.com or call 913-499-8391.