Hornady has revolutionized long-range shooting with its new Extremely Low Drag (ELD) bullets. These flat-

shooting projectiles are a boon to designated marksmen who need to make precise shots on hostile targets at very long range.

- RELATED STORY: Exclusive: Hornady’s New ELD Series Expanding Rifle Ammo

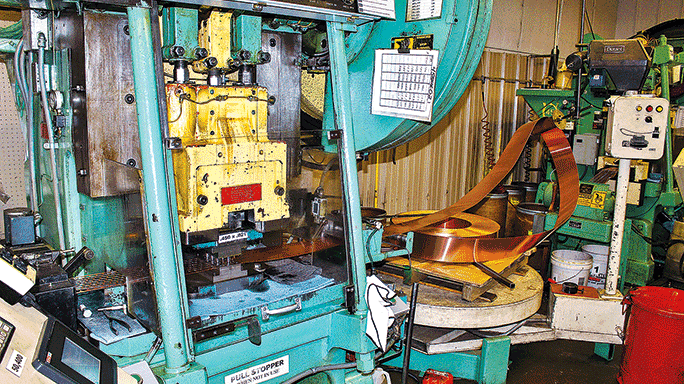

ELD Match and ELD-X bullets combine Heat Shield polymer tips with Advanced Manufacturing Process (AMP) gilding metal jackets. This gives them flatter trajectories and less wind drift than other types of match-grade projectiles. How did Hornady achieve this? The answer came by taking a different approach to looking at the effect of drag on a bullet as it flies through the air.

The Doppler Effect

Advertisement — Continue Reading Below

Normally, ballisticians calculate ballistic coefficients (BCs) by looking at the design of new bullets and comparing them to a standard reference that’s based on the design of a projectile with well-known ballistic performance. Most use the G1 standard from the late 19th century. This standard is based on an artillery shell with a tangent ogive. Ballisticians then check their calculations with two or more chronographs placed at varying distances to see if the bullet is performing as anticipated. However, a chronograph only measures velocity at a specific distance, and you’d have to use at least 25 of them set at different distances to develop a truly valid performance curve. The problem with this method is that it’s expensive and very time consuming to set up enough chronographs to get an adequate sample to determine a bullet’s true trajectory and wind drift out to 1,500 or 2,000 yards. So, at best, the BCs published in manuals are very approximate estimates of the effect of drag on a bullet.

Enter Doppler radar. The ballistic engineers at Hornady realized that there had to be a better method, so they decided to see if Doppler radar would give them a better way of determining a bullet’s velocity, time, distance and drag during flight. Unlike BC, Doppler radar is not a calculation based on a standard. Doppler radar provides exact measurements every one or two feet. So if you shoot out to 2,000 yards, you have a minimum of 1,000 precise reference points for your curve. This makes it possible to have an accurate coefficient of drag for your bullet and predict its performance based on its initial muzzle velocity.

Like all science, this sounded really simple until it was applied. That’s when science threw Hornady engineers a curve. When firing polymer-tipped bullets at over 2,800 fps, the radar indicated that drag suddenly increased right after the bullets left the muzzle. Was there something happening to the polymer tip? Sure enough, the engineers checked and found that the melting point of the plastic tips was between 320 and 345 degrees Fahrenheit. It only took about 0.1 to 0.15 seconds after the bullet left the barrel for aerodynamic heating to cause the bullet tips to reach their melting point. The melting continued until the projectile slowed to about 2,100 fps, when the tip cooled sufficiently to again become solid. By that time heat from friction with the air had changed the shape of the tip, increased drag and degraded the bullet’s velocity, trajectory and ability to resist drifting.

Advertisement — Continue Reading Below

Hornady’s solution was to use a polymer with a higher melting point for its new Heat Shield Tip. In addition, the company gave the tip a wider shank. This acted as a heat sink, causing the new tip to heat more slowly than other polymer tips. When combined with Hornady’s AMP jacket technology, which produces a secant ogive bullet jacket that is very concentric and also very consistent in its thickness, the result was the new ELD Match bullet, which retained its velocity better, had flatter trajectories and drifted less than competitors’ bullets.

Ballistic Upgrade

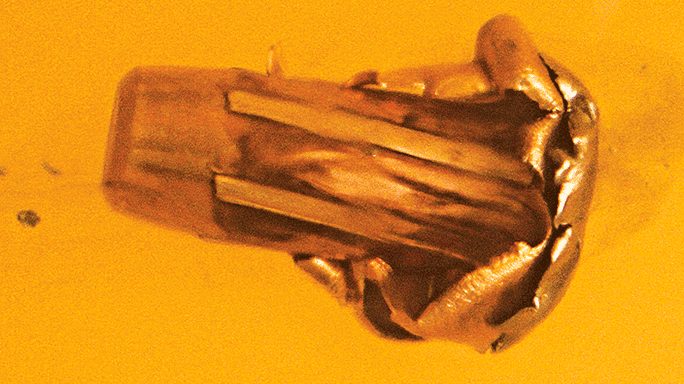

Match bullets are great for punching paper, but they leave something to be desired when bullet meets bruin. To incapacitate an animate target, a bullet has to stay together and penetrate deeply in a straight line despite striking barriers, heavy bones or other structures that could stop or deflect it. Given that the ELD bullet is a cup-and-core design and not a bonded or copper-based monolithic projectile, something also needed to be done to ensure the jacket and core would not separate under the stress of impact. Therefore, the bullet’s gilding jacket needed to be thicker to help keep it together under the stress of impact and the increased rearward thrust of the Heat Shield’s larger shank. But making the jacket too thick would limit expansion, especially at long range.

Advertisement — Continue Reading Below

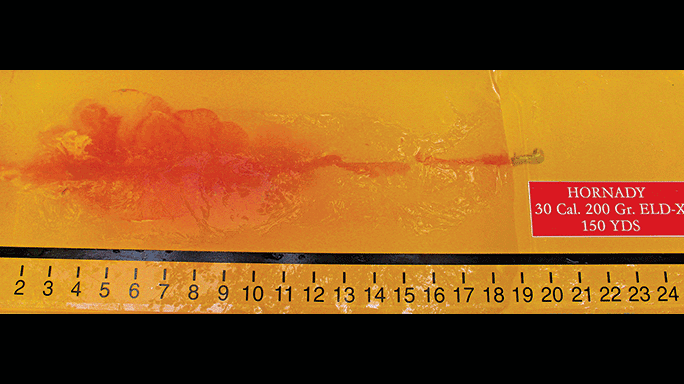

To solve this, the engineers added Hornady’s well-known InterLock ring to the jacket. But even this didn’t seem to be enough until they moved the InterLock forward toward the tip of the jacket. This strengthened the bullet’s resistance to jacket/core separation. The end result is a bullet that expands to at least 1.5 times its original diameter and has a controlled energy release while penetrating between 18 and 24 inches in 10-percent ballistic gelatin. The fragmentation is minimal while the penetration is straight. This bullet performs as well in gelatin at 800 yards as it does at 150 yards.

Real-World Testing

Of course, no one hunts gelatin, and gelatin never attacks civilians, police officers or soldiers. In other words, gelatin tests have significant limitations as models for real-world bullet/target interactions. So, Hornady hunted with the ELD-X bullet in Africa and North America to check its terminal performance. Seventy game animals ranging in size from antelopes to elk and eland were taken at distances of 65 to 865 yards, and not one animal was lost. That testifies to the skill of the hunters as well as to the accuracy and consistent terminal performance of the ELD-X bullets.

Advertisement — Continue Reading Below

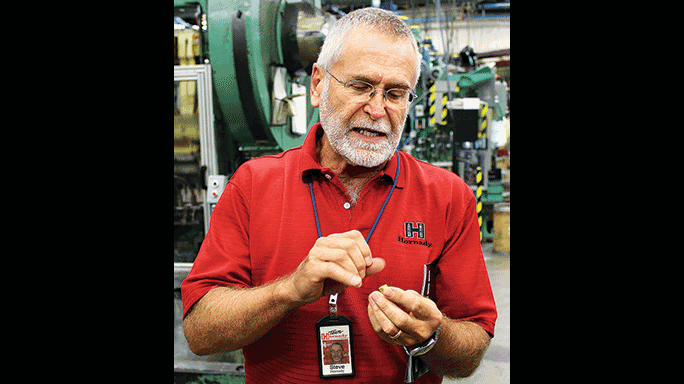

This past October I was invited to one of two media events at the Hornady factory. We reviewed the development of the ELD Match and ELD-X bullets, toured Hornady’s manufacturing facilities, tested the bullets in gelatin and spent a day shooting the ELDs at targets that were so far away they were difficult to see without a scope. Hornady’s engineers spotted for us and doped the wind. Hits out to 800 yards were almost routine, and I even hit a man-sized silhouette at 1,200 yards in a gusting crosswind!

- RELATED VIDEO: Hornady’s Powerful New Full Boar Ammo

The terminal performance of ELD-X and ELD Match bullets in tactical scenarios is yet to be fully determined, but these new projectiles appear to hold promise for use by designated marksmen. The ELD-X is a tough bullet and should perform well against many barriers and still penetrate well. ELD Match bullets aren’t designed for penetration and may therefore be useful in environments where there is a higher risk of collateral damage. There’s even a potential benefit for police administrators: ELD Match and ELD-X bullets cost 33 and 40 percent less than bonded bullets or monolithic bullets made of copper-based metals. Whether you’re an officer, a competitive shooter or a hunter, these new Hornady bullets show a lot of promise.

For more, visit hornady.com or call 800-338-3220.

Advertisement — Continue Reading Below