Gun sales have skyrocketed in the past few years, causing a massive demand for ammunition. As a result, all stateside ammunition companies have been working overtime to keep up with the demand. Good luck trying to find ammo for an uncommon round. What to do? Make your own!

Boom! How To Make Gunpowder

Boom! The 124-grain 9mm jacketed hollow-point projectile leaves the barrel at 1150 feet per second striking the 10-ring target dead center at 15 yards. So how did we get to boom?

Advertisement — Continue Reading Below

A bullet doesn’t just shoot out the end of the barrel. A lot goes behind a bullet to make it work. So, let’s take a very brief and straightforward look at what makes up ammunition before we get into making gunpowder.

Ammunition is made of several components. The components that make up modern ammunition are; a bullet, case, primer, and gunpowder.

• Bullet. Plain and simple, a bullet is a projectile, albeit a fast-moving projectile, that can prove devasting if encountered firsthand, i.e., getting shot with one.

Advertisement — Continue Reading Below

• Primer. A primer is a small cap that holds a slight explosive charge. When the primer is struck, it causes an explosion that ignites the gunpowder.

• Gunpowder. The primer ignites the gunpowder, causing an explosion that pushes the projectile through the barrel.

• Case. The case holds the bullet, gunpowder, and primer in place.

Advertisement — Continue Reading Below

Add all the pieces together, and you have ammunition.

Now Let’s Make Gunpowder

Gunpowder is one of the critical components in the ammunition mix. Three main ingredients make up gunpowder; all can be found at major home-building stores.

1. Potassium Nitrate, also known as saltpeter. Potassium Nitrate is typically found in stump remover.

Advertisement — Continue Reading Below

2. Charcoal. Yes, the same charcoal used to cook up steaks on the grill.

3. Elemental Sulfur. Found in the plant section and used for soil.

Now that you have just returned from the store and have your ingredients, you need to mix it all up. But first, let’s talk about safety.

Advertisement — Continue Reading Below

Proceed With Caution

Gunpowder can be dangerous. Anytime you work with explosive materials, you need to be cautious. Throughout history, gunpowder explosions have caused massive carnage. Hence the warning to be careful when dealing with explosive materials. Leave the matches, lighter, or other flame-producing items out of the area.

Mix It Up

The National Park Service, yes, the Park Service, provides details on how gunpowder is made. Their site states, “The current modern ratio of 75% nitrate,15% charcoal, 10% sulfur was settled upon sometime in the mid-18th century in England.”

Advertisement — Continue Reading Below

You will need the proper equipment to blend and mix the ingredients. For starters, you will need a mortar and pestle set. You may have seen a set of these at your favorite Mexican restaurant mixing a batch of guacamole.

You will also need a small amount of water and a safe container to store the finished gunpowder.

All these items are readily available at the same home-building store where you purchased the ingredients.

• Step One. Mix each ingredient separately using the mortar and pestle set, ensuring the powder is fine.

• Step Two. Measure the ingredients and blend them using a small amount of water: 75% nitrate,15% charcoal, and 10% sulfur.

• Step Three. Use a strainer and pass the mixture through until it is fine.

• Step Four. Store it in a safe place until ready to use. The best bet may be out of the house and in a special fireproof container.

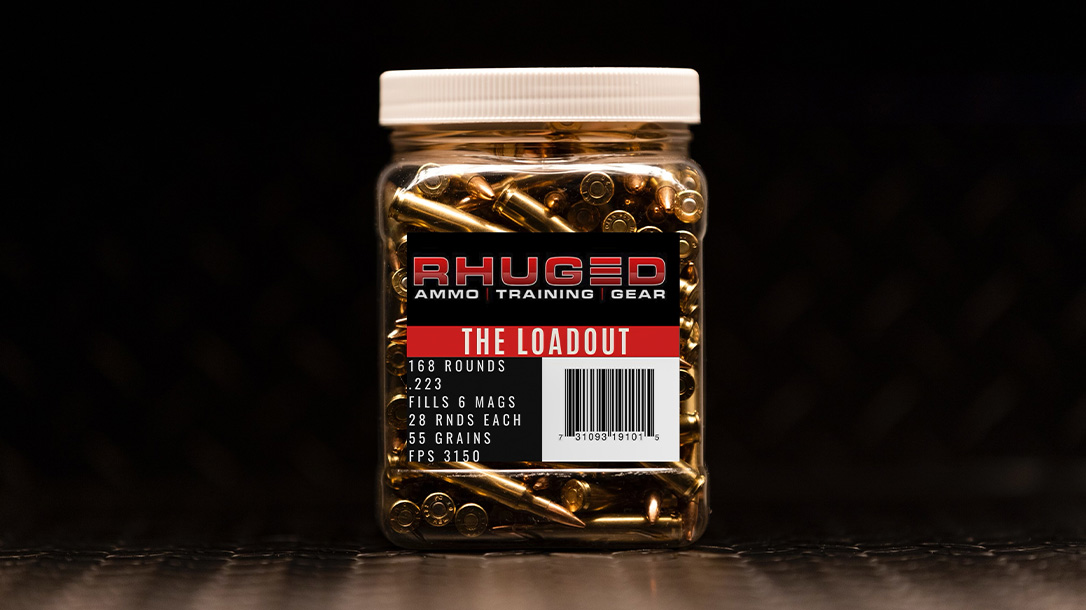

Ammo Prices High? Buy Direct

As fun as making gunpowder for your ammo would be, the safest bet is to purchase ammo from a reliable company. Unlike a homemade batch of gunpowder, ammunition companies are subject to rigorous standards for reliability and safety.

Chris Osman, former Navy SEAL and Marine, owns Rhuged. Rhuged is an ammo, training, and gear company based in Las Vegas, Nevada.

Chris sources brand-new brass and components from U.S.-based companies at scale. Rhuged manufactures millions of rounds a year. Small companies like Rhuged can keep costs down by selling directly to consumers. Chris says, “We sell direct to the consumer, directly to the actual shooter. If I sold into the other sales channels, it would cause markup; our ammunition would be the same price as others. People confuse price with quality.”

Let’s talk about safety. Is it safe to buy direct from a smaller-scale manufacturer? Chris told me, “Ammunition is made to an exact specification through SAMMI standards. If you don’t, the ammo will not work. You have to build it to these publicly available specs. If you pull our bullet apart, it is the same specs as Remington, Federal, or any manufacturer.”

Chris mentioned SAMMI. SAMMI is the Sporting Arms and Ammunition Manufacturers’ Institute, created in 1926 at the behest of the federal government. SAAMI creates and publishes these exacting industry standards to ensure firearms and ammunition are safe. Chris and other small manufacturers compete against legacy, not quality.

Now that you’ve made all that ammunition, where are you going to keep it? Maybe you start by reading this article: Where To Store Ammo At Home