I have used and owned several custom 1911 pistols. My first, a Colt Government Model in .45 ACP, came in 1983. Owned and carried by a nationally ranked IPSC competitor and deputy sheriff, it was an impressive gun. And it wasn’t a race gun—he carried it every day. It didn’t have lasers or phasers—it was just well built, finely tuned and fitted by hand. Watching him put eight rounds into an inch or two from off-hand at 25 yards started me on my 1911 journey. Yep, he was a superb shooter, and he sparked a training ethic in me that I’ve never lost, but the pistol was a big part of the equation.

A few years later, I used my first Wilson’s Gun Shop 1911, one Bill Wilson personally worked on, during a first Thunder Ranch class. Since then, I’ve mostly carried custom 1911-style pistols for duty and concealed carry, and they’ve all been working guns. While I use high-capacity 9mms for training, teaching and other events, my preferred personal-carry pistols remain either of my two custom 1911s.

I have since altered and built 1911 pistols, a process that has provided a unique perspective for a gun writer. Building a 1911 by hand may not be rocket science, but it doesn’t suffer fools. For some, it’s about the artwork; others, the attention to detail. Custom 1911s remain incredibly popular—that won’t change any time soon—and another craftsman as entered the arena of 1911 builders: Jesse James.

Advertisement — Continue Reading Below

Meet The Maker

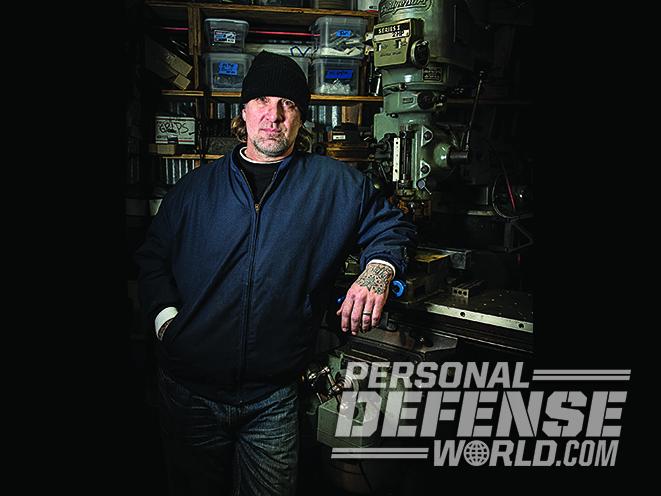

Jesse James started as a metal worker and welder. Early in his career, he identified a need for a fat-tire motorcycle fender and built one. He expanded into custom-built parts and eventually motorcycles, ultimately creating West Coast Choppers. As you probably already know, Jesse’s custom motorcycles are some of the most sought after in the world. Jesse went from welder to custom builder to television star. Following that fame, Jesse vanished from the mainstream, leaving California for Austin, Texas. Happily settled into his new digs, he has been quietly building his next venture: Jesse James Firearms Unlimited, or JJFU.

The opportunity to meet and train with Jesse arose out of a recent media event. After working in law enforcement for more than three decades, I’ve learned a thing or two about reading people. That’s just the way it is for a cop. I lived this long by being really good at it, and I prefer to meet people and assess them without listening to any hearsay. To that end, I found Jesse to be nothing like his “press.” He was quiet, personable and openly looking for input on his pistols and rifles. He truly loved building and using them and just wanted to get better—the marks of some of the best arms-makers in the industry. His rifle worked pretty well and was clearly custom made, which prompted me to request one of his 1911 pistols and visit his garage in Austin.

Advertisement — Continue Reading Below

To The Shop

Every dedicated custom 1911 builder I have ever met started in their garage, and Jesse James is no exception. All of his guns are built in a large garage behind his home. Until recently, his shop help consisted of his son and several French bulldogs. His son has moved on, but the dogs remain, and Jesse has just hired Dave Gregor to mostly help with 1911 builds. Upon my arrival, the dogs all met me on the driveway and kept us company throughout the visit.

The state of-the-art shop everyone seems to think he uses is down the street, building motorcycles. That shop does machine his custom AR receivers, grips and handguards, but these components all end up in his garage for fitting. The receivers are all purposefully oversized so Jesse has to personally fit each component by hand.

Advertisement — Continue Reading Below

- RELATED STORY: 11 Custom Gun Shops For 1911 Pistols

Along with the normal DRO-equipped mill and lathe, Jesse has a forge for metalworking along with tools for open die forging, including large power hammers. A billet of his custom-designed Damascus steel sat on a bench. Dies for receivers and slides sat next to it, ready to be used on his custom-made 1911 pistols. Two Damascus steel builds sat on his bench along with a couple of AR-style rifles. Every part of these guns is hand-fitted and polished. It doesn’t get more “custom” than that.

Jesse’s dogs surround him, and his oldest dog has a special spot under the bench. It reminded me of my office, where my dog, Missy, sits at my side all day long. It’s amazing how often custom builders are surrounded by man’s best friend. Nothing about this place fits the image of Jesse James created by the media. While there are no illusions as to his wealth, he acts nothing like a celebrity or a typical person of means. As he is fond of saying, he is “just a welder that got lucky,” and that is exactly how he acts. Having spent a few hours talking to Jesse, I headed back to my home range, excited to put his Cisco 1911 to the test.

The Cisco Kid

Advertisement — Continue Reading Below

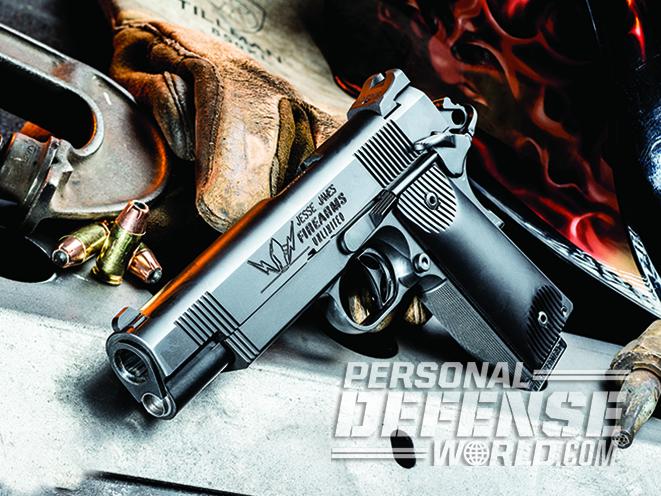

The Jesse James Cisco is an entry-level custom pistol. My test pistol was built using a JEM Guns frame and an STI slide. The Master series frame has an extended dust cover without a rail that nicely matches the slide. The high-cut grip features 30-lines-per-inch (lpi) checkering and a slightly beveled magazine well. JEM matches its grip safeties and mainspring housings to its frames, and both were used here.

Jesse machines his own grip panels from 6061-T6 aluminum with grooves at the top and bottom of each panel that match the rear cocking serrations. The gun’s internals are made of tool steel—no MIM parts here—and they’re all fitted by hand. The safety is ambidextrous while the magazine release button is extended. Beneath the skeletonized hammer, the grip safety is also extended.

The slide houses a ramped, match-grade barrel that is held in place with a nicely fitted barrel bushing. Sprinco’s Recoil Management Guide Rod System is also installed. The gun’s front and rear Heinie SlantPro sights are black and serrated. The whole package came in a black hard case with an eight-round Tripp Research magazine.

Advertisement — Continue Reading Below

My first task was to run my hands along all of the gun’s edges, and none were sharp. The grip safety fit well when compressed with no protrusions to cause discomfort at the web of the hand. The beveling on the slide was mild and not sharp, but not every edge was removed. The slide’s front and rear cocking serrations match well for a very nice look. The trigger was crisp at about 4 pounds with no overtravel. The Cisco’s slide-to-frame fit was very tight with no side-to-side play. This test gun, Jesse’s “triple black” model, was coated entirely in black nitride with a moderate gloss. It’s not flat, but it’s not glossy, either.

Ready To Run

Other than the obligatory group and velocity testing, I tried to limit my time on the square range with the Jesse James Cisco. I practiced drawing the pistol from a Raven Concealment Systems holster for my off-hand (left) side due to injuring my strong hand a few weeks prior. Once dialed in, I ran the gun through several exercises working inside and around my truck. I mostly used D&L Sports magazines to run several types of ammo through the Cisco. Custom pistols are often as much art as function. But I’m not much of an artist, so I ran this pistol pretty hard.

Advertisement — Continue Reading Below

The Cisco functioned flawlessly while using every type of ammunition I fed it, including some of Hornady’s steel-cased 230-grain HAP rounds. During testing, Sprinco’s Recoil Management System kept things controllable. The slide locked back after emptying every magazine, including those from Wilson Combat, D&L Sports, Chip McCormick, Tripp Research and ACT-MAG. I fired the gun from prone, in the dirt, and from various positions without a hitch. As I came to discover, my left-side grip was less than optimal, yet the Cisco kept working even without a death grip. It was very well balanced and easy to control while moving inside and around my truck, an FJ Cruiser.

- RELATED STORY: How To Build Your Own 1911 Pistol At Home

The Cisco’s accuracy on the move was solid, especially when I switched to using my strong hand. It wasn’t possible to get a solid support grip with my injured index finger. My first-round hits were good, though controlling recoil was more difficult. After moving back to the strong side, that finger just operated the trigger. My accuracy also improved, along with my control.

Making the transition with the pistol was much more difficult than with a rifle or shotgun. It was easier in some cases to shoot single-handed from the left side. It was also a bit more difficult to overcome the urge to use my dominant eye instead of my left. Reholstering was an adventure as well. It’s one thing to stand on the line and switch hands, but a whole other thing to shoot from, around, behind or under real-world obstacles. That’s just another reason to get off the square range when you can and back into the real world if possible.

During my testing, the Jesse James Cisco was as accurate as any 1911 I’ve tested that wasn’t designed for competition. My best group was accomplished using some old Hornady Steel Match ammo, measuring just a tad over 1.5 inches at 25 yards. My test groups were fired using a Wiebad Pump Pillow from the bumper of my truck, not a bench or a Ransom rest. The pistol cut a big hole in the paper at 15 yards and in. That’s as good as I can shoot. I’m not sure how it would get any more accurate; maybe I could, but not the Cisco.

Top Quality

The Jesse James Cisco is a solid custom 1911 pistol built using excellent parts and attention to detail. It worked with all types of ammunition in less-than-pristine conditions. It’s as accurate as I can shoot a pistol. The gun’s fit and finish is excellent, commensurate with its $4,299 price tag. You can pay more for a semi-custom 1911 these days built with much less attention to detail.

Jesse James is a master at metalworking and machining. He brings a ton of experience to the process, just like many custom makers. Few build them from their own forgings, which is something Jesse can do. He is still learning the build side, but so far he is doing an excellent job. Adding someone like David Gregor, who has years of experience in creating guns for warfighters, will only make things even better. It should prove an excellent combination.

Most importantly to me, I made a friend. Jesse impressed me as a hard-working man who is honest, forthright and honorable. I found him to be a good man dedicated to the craft. His custom builds are as much art as firearm, and that’s fantastic. Mastering metal and building from the ground up is a fading art, and I for one hope Jesse and others like him keep it alive. The industry will be better for it.

For more information, visit http://www.jjfu.com or call 888-269-0666.

This article was originally published in ‘Combat Handguns’ February 2017. For information on how to subscribe, please email subscriptions@