Most military-oriented guys like me enjoy Hummers. That’s not because they are better than other 4×4 vehicles. It’s more because of their personality. The appeal of the AM General HMMWV (aka “Humvee”) is what spurred GM to build its H1, H2 and H3 series vehicles. And it’s what made my friend Al de Orleans build his own recon-style Hummer H3.

Not Really Tactical

Hummer actually built a “Tactical Edition” of the H3. I’m told only 1,000 were made, and it was nothing more than an H3 with blacked-out trim. It had a body-color grille, a black wraparound brush guard, black tubular assist steps and a black spare-tire cover. It was available in red, black and Boulder Gray. But the H3 Tactical Edition was a lost chance for GM to make a truly tactically enhanced Hummer.

Advertisement — Continue Reading Below

Perhaps learning from the mistake, GM realized its customers wanted more a more hardcore 4×4 and offered the Alpha version in 2008. It had some features aficionados wanted, such as a 5.3-liter V8, a 4:1 transfer case, a rear locker, 4.10 gears and an upgraded suspension. But a tactical version was never made, and GM eventually cut its Hummer line.

Al’s Custom Build

My friend, Al, got his H3 because he always wanted a Hummer. He had no plans to drive it much, and he knew how limited the H3, with its weak independent front suspension (IFS), would be.

So, Al waited before getting his Hummer. He eventually waited two years for the H3 Alpha to come out because he knew the standard I5 engine was too weak, and he needed a V8 under the hood. Getting the Alpha was an adventure, as he couldn’t find any in California that weren’t covered in chrome. Finally, after a six-month wait, he got what he wanted: an H3 Alpha not covered in chrome, without a sunroof but with the Adventure Package for the rear locker and a 4:1 transfer case.

Advertisement — Continue Reading Below

The project started slowly, as Al only planned some modifications to make the vehicle more attractive: just some cosmetic modifications and a Rancho lift on 33s, because the 35-inchers would stretch the front-end reliability.

While sourcing an installer in Southern California, he contacted Off-Road Evolution in Fullerton and got hooked. He saw the company’s solid axle conversions and coilover suspension kits, and asked about a Hummer version. He was then told Off-Road wanted to make a kit and asked if he would volunteer his Alpha for the research and development. That sounded great but still looked too expensive, and Al was worried about the electronics being affected by the modifications. Then Al learned that Dynatrac was looking to make the first 100-percent electronically compatible axles, and he could get them for free. Who could say no?

Exterior

In a previous Chevy El Camino project, Al worked with Duane, Rafe and Bernt from Boyd Coddington’s custom shop while filming an American Hot Rod episode. Thus he knew who he wanted to fabricate his exterior modifications.

Advertisement — Continue Reading Below

One day while having lunch with Bernt, Al mentioned his H3 and plan to show it at SEMA and SHOT. Bernt liked the idea and added that he should do a crazy thing with it: cutting the roofline even lower, like the gangster-style hot rod. Al said no thanks, but he wanted to make it look like a military Humvee.

The Off-Road Evolution guys were a tad slow with the suspension and axles, so Duane and Bernt started their slant-back part of the project. They basically cut out the entire rear end and refabricated it. They then reinforced it from inside and repeated the process on the tailgate side. Bernt made this by hand from scratch—all hand-rolled and hand-hammered into shape—with no electrical or hydraulic forming tools. It was pure metal fabrication art.

Lighting

The custom team wanted to switch out the lights for the military Humvee models, and Al wanted to take it a step further and perform the upgrade with modern LED versions of military lighting. The problem was integrating the lower-resistance LEDs into a system designed for incandescent bulbs. Fortunately, Duane is an electrical genius and figured it out without much of a hitch.

Advertisement — Continue Reading Below

The rear lighting was the most labor intensive. The team had to fill out the old OEM taillight housing. The tricky part involved recessing them some for more protection. The rear side markers weren’t much of an issue and were upgraded from the amber color by swapping the lenses with red ones.

After the body work was finished, the H3 was put on a roller and taken away for painting the body and small parts. The team chose Brownells’ Aluma-Hyde II coyote tan color—the same one many of us use to coat our weapons. The color was selected so the H3 would not impersonate a true military vehicle while also making touch-ups easier. Of course, official military colors are olive drab and desert tan, which are much lighter.

After painting and adding four anchor points on the slant-back exterior, the team got the interior to match the OEM one and make the H3 look like it came that way from the factory. The only addition would be a six-point roll cage. Gabe, the upholstery guy, hid the roof-liner extension under the roll cage.

Advertisement — Continue Reading Below

Axles & Suspension

One reason the build was delayed was the axles. Dynatrac was still doing research and development for building the first aftermarket axles that would be 100-percent compatible with the OEM electronics. Dynatrack’s ProRock 60s are heavily modified 60s with a ground clearance of 44, and they can survive the heavier Hummer and V8 power. Ultimately, Dynatrac delivered a superb set of heavy-duty axles in time to keep the build rolling.

The H3 dimensions differ from those of a JK, so the Off-Road Evolution team had to design a new system with custom geometry engineered for the H3. The advantage of this setup is that you have an 8-inch coilover placed horizontally next to the frame rails, which puts out 14 inches of travel. If you had a 14-inch coilover, it would have to go into the trunk space, like on Baja race trucks. It’s a trick setup that works well—so much that F1 and Indy cars use it.

The good thing about the H3 having the 5×5.5 Jeep CJ wheel pattern is that the team could play with many wheels, as CJ wheels are cheap and available everywhere. At first, Al tested the H3 on 42s, and they were too big and rubbed everywhere. Then he installed Hutchinson Beadlocks with 37-inch IROKs for off-road use before upgrading to 40s because there was room to spare in the wheel wells.

Advertisement — Continue Reading Below

Finishing Touches

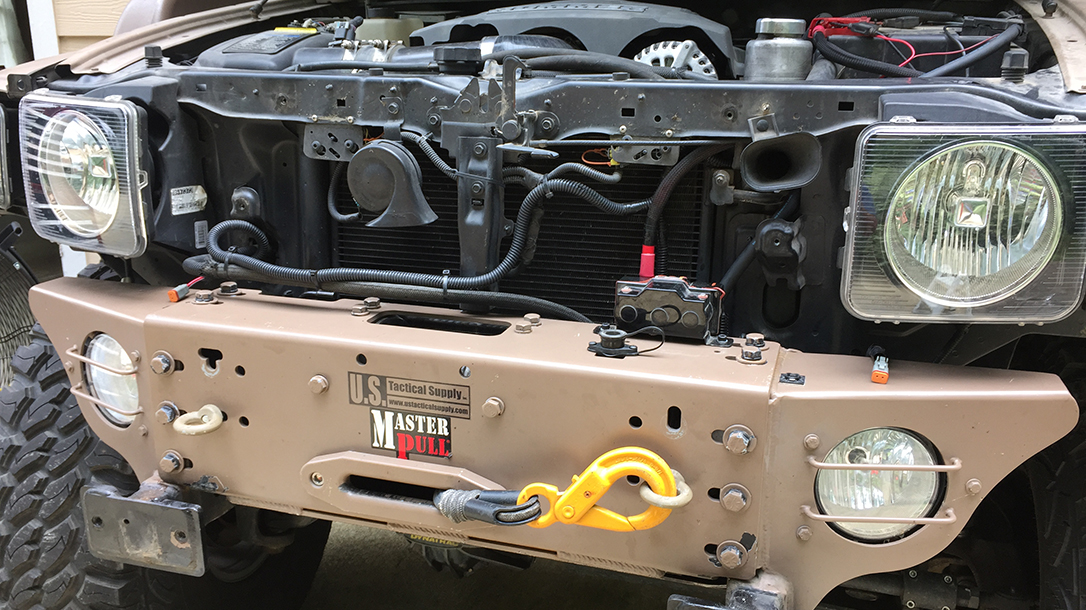

Now it was time to make a bumper and winch mount. Winches rated at 9,000 pounds would eventually burn out with the weight of the H3, so Al decided to install a Warn short-drum M12000 winch in the huge empty space created when the team removed the IFS front-axle setup.

The next step was the rear bumper. The factory ARB bumper is well made, but it had no provisions for mounting the factory backup cam, so the team made a custom mount and fabricated a second D-ring in place of the license plate.

Most of the work was done, so Al started driving the Recon H3 and found he needed a steering ram assist, which he installed along with front and rear Currie AntiRock sway bars. Initial tests also exposed some flaws, but nothing serious. The left side e-brake had been routed badly and would get extremely tight. The heim joint on the pitman arm was also at its limit and could pop out, and the front and rear axles were not centered and were rubbing.

Despite that, every test attracted crowds to see the unique slant-back H3 with a solid-axle conversion. The project was a success. Then, while Al was moving from California to North Carolina, he decided to take the H3 to Las Vegas for the SHOT Show. There, it became a centerpiece during the Media Day at the Range portion of the show.

Recon H3: Final Thoughts

The Hummer H3 Recon he built has been featured in several magazines. It attracts attention everywhere and works flawlessly, as I can testify. On my last visit to Al’s North Carolina residence, he let me drive it around. It was impressive to say the least. In the end, this is the tactical H3 that GM should have built.

This article was originally published in “Tactical Life” August/September 2018. To order a copy and subscribe, visit outdoorgroupstore.com.