Even with all of the success that polymer-framed semi-autos have experienced since the “plastic” Glock first came on the scene in 1985, I wouldn’t have thought that a polymer-framed revolver would have stood much chance at commercial survival with today’s gun-toting market. Again, thanks to Ruger, I have been proven wrong.

Following close on the heels of their very successful .380 ACP-chambered Light Compact Pistol (LCP) released in 2008, Ruger announced their Light Compact Revolver (LCR) in 2009, chambered in .38 Special and rated for +P ammunition.

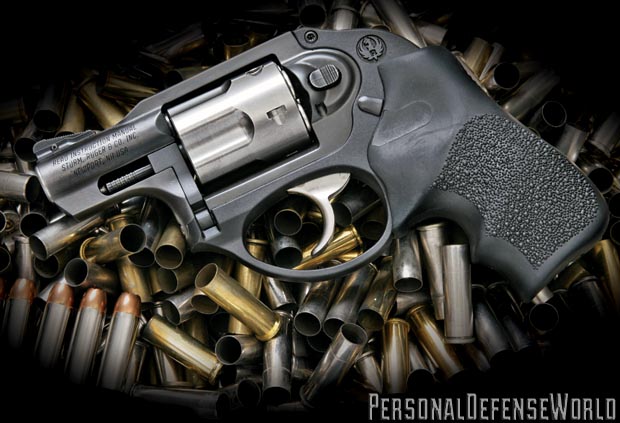

In its original incarnation, the .38 Special-chambered LCR weighed 13.5 ounces, attributable to its composition of glass-filled nylon polymer, aerospace-grade aluminum, and stainless steel. In 2010, Ruger has released a new model LCR, this one chambered for the formidable .357 Mag cartridge.

Advertisement — Continue Reading Below

Gun Details

The polymer part of the LCR that made it so revolutionary in terms of revolver manufacture remains essentially unchanged on this new snub. It’s molded from long-strand, glass-filled polymer and comprises the back and lower portion of the LCR’s framework. It houses most all of the components that make the LCR go bang—the hammer, trigger, mainspring and strut, transfer bar and all attendant springs and pins. Its “hammerless” design makes the LCR a double-action-only proposition, as no hammer spur presents itself for cocking. Also contained herein is Ruger’s manually operated internal gunlock, which is key-operated and visible and accessible only when the LCR’s grip is removed. The LCR incorporates Ruger’s patented transfer bar safety system, preventing its hammer from contacting the firing pin unless its trigger is pulled all the way to the rear. Since most of the internal parts are installed through the top of the fire control housing, no sideplate is present, which adds considerably to the strength of this assembly. Since it’s ready to use right out of the mold, no hand-fitting of internal parts in this lower assembly is required, keeping costs down, and the same assembly is used on both the .38- and .357-chambered models.

The second component of the LCR’s framework is called the frame sub-assembly, and this houses the cylinder and barrel. On the powerful .357 model, this assembly is made from a casting of strong 410 stainless steel. The front sight on the LCR is a serrated ramp affixed to the frame sub-assembly via the use of a rolled crosspin, making it easily replaceable if damaged.

Advertisement — Continue Reading Below

The barrel, as well as the cylinder on the .357 Mag LCR, is fabricated from Carpenter 465 stainless steel. This material has a much higher yield strength than the 17-4 pH aerospace-grade stainless steel used in the +P-chambered LCR, since pressures generated by the magnum round can approach something close to twice that developed by the Special.

Grips on the .357 are of the one-piece mono-grip design from Hogue and fasten to the LCR via the use of a bottom screw. The trigger pull on this double-action-only revolver is surprisingly smooth and light and not what one would expect from an out-of-the-box snub-nosed piece. From a fit-and-finish standpoint, the Ruger LCR looks a little unorthodox but functioned quite well from the get-go. The LCR had a solid in-the-hand feel. Its cylinder timed and locked up well on all five chambers and exhibited minimal cylinder movement either fore and aft or side to side at full lock-up.

Range Time

Advertisement — Continue Reading Below

I can honestly state that I wasn’t particularly looking forward to my range session with this piece. Some guns are a “hoot to shoot,” but I’ve never found that to be the case with most handguns chambered for the .357 Mag cartridge—especially so if it’s either small, short-barreled or light. But it’s my job, so I gathered up a pretty good representative sample of .357 Mag commercial loadings and headed for the range. Since Ruger advised that the LCR sights are regulated at 15 yards distance, I saw no reason to put my targets any further out than that.

The first .357s I fired through the LCR were some 125-grain JSPs from Winchester’s USA WinClean line. Velocities with this round averaged 1,177 feet per second (fps) out of the little Ruger’s 1.88-inch barrel, and I was immediately struck by the intense concussion and increase in muzzle flash with those first rounds fired. There’s a lot more going on when magnums are loosed from this diminutive pistol.

I worked my way through five different .357 commercial loadings and came to appreciate the well-thought-out grips from Hogue. They helped a great deal in making this little powerhouse shootable with these high-intensity rounds. Groups with this longer-cased ammo were not quite as small as those obtained with the .38 Special fodder but were well centered and closer to point-of-aim than experienced with the lesser-powered rounds. The greatest muzzle energy was obtained with the 140-grain JHPs from CorBon. Velocities with this round averaged 1,185 fps out of the LCR’s abbreviated tube, producing well-centered groups and 437 foot-pounds of energy in the process. The LCR loaded with magnums was definitely a handful, but not quite as bad as I had originally envisioned.

Advertisement — Continue Reading Below

Like the .38-chambered LCR, I think Ruger’s got a winner here. It’s the same overall size as the lesser-chambered gun and only weighs in at about 3.5 ounces more. It’s got a great out-of-the-box trigger, good sights and a comfortable grip. If you can control it, you’re good to go. If not, it shoots the .38 Special round just fine. Find out more by visiting ruger.com.