The 9mm submachine gun, specifically the Heckler & Koch MP5, has been the darling of the special operations and SWAT communities for over 40 years. It has also been the preferred weapon for protective details around the world, including the United States Secret Service, where it replaced the venerable Uzi. However, the MP5 suffered from being chambered in 9mm, placing it at a severe disadvantage in some operational environments.

- RELATED VIDEO: LWRC’s Ultra-Compact IC-PDW in 5.56mm NATO

In recent years, many units have recognized the need to replace the MP5 with a more potent cartridge, with improved terminal ballistics and the ability to penetrate body armor and barriers. The need for a new personal-defense weapon (PDW) platform was quantified when, in 2012, the Department of Homeland Security issued a solicitation for up to 7,000 PDWs. The solicitation, HSCEMS-12-R-00011, is easily found on several government websites and is considered open source. To quote the document, “DHS and its components have a requirement for a 5.56x45mm NATO, select-fire firearm suitable for personal-defense use in close quarters and/or when maximum concealment is required.” The specifications state, in part:

- The firearm shall be able to be operated by a left- or right-handed user without permanent modification.

- The action shall fire from a closed bolt.

- The action shall be gas operated.

- The action shall be capable of accepting all standard NATO STANAG 20- and 30-round magazines and Magpul 30-round PMAGs.

- The trigger pull shall be not less than 5.5 pounds and not exceed 9.5 pounds.

- The overall length of the firearm shall not exceed 30 inches with the stock fully extended.

- The overall length of the firearm shall not exceed 20 inches with the stock fully retracted and/or folded.

- The unloaded weight of the firearm (without magazine) shall not exceed 7 pounds.

- The barrel shall have a rifling twist of 1 in 7 inches.

- The front forend shall incorporate MIL-STD-1913 Picatinny rails on the top, bottom and both sides to accommodate the attachment of optics or accessories.

- It is desired that the forend Picatinny rail sections be capable of being removed or added.

- The front and rear sights shall be capable of being folded and/or removed.

- Each firearm will be rated for its initial accuracy at 50 yards. The average extreme spread of five 5-shot groups shall be no greater than 2.5 inches.

It is rather obvious that the DHS is following an emerging trend of replacing legacy PDW platforms, predominately the MP5 9mm submachine gun, with a similarly sized platform in 5.56mm NATO. The MP5A3, with its collapsible stock, weighs 5.97 pounds and has an overall length of 26 inches with the stock extended and 19.3 inches with the stock collapsed. This is close to the 30- and 20-inch requirements of the DHS solicitation. It should come as no surprise that units within the U.S. military are also very interested in a PDW platform.

Advertisement — Continue Reading Below

In 2013, I had the privilege of visiting LWRC’s plant in Cambridge, Maryland, to evaluate a new Six8 IC-PSD that had been developed for the Saudi Royal Guard. While there, I was able to examine the prototype of the IC-PDW. I immediately, if not prematurely, put my name on the non-existent list to get one when the semi-auto-only SBR version became available.

Gun Details

When the little 5.56mm arrived, I had a hard time containing my enthusiasm. When compared to a standard 16-inch-barreled carbine, the IC-PDW is tiny, with an overall length of just 20.5 inches with the stock collapsed. The IC-PDW is based on the forged Individual Carbine upper and lower receivers that are the foundation of the IC family. The IC lower receiver features fully ambidextrous fire controls as well as a flared magazine well. The safety/selector and bolt release are mirrored on both sides using the same control part. The left-side magazine release is a large paddle that is recessed between two raised ribs to prevent inadvertent magazine dumps. The pistol grip is Magpul’s excellent MOE-K grip.

Advertisement — Continue Reading Below

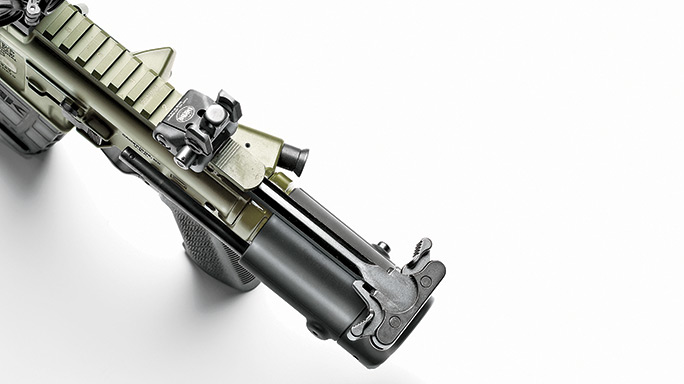

The Monoforge upper receiver features a low-profile rail that has threaded positions on the 3, 6 and 9 o’clock axes, allowing the user to mount rail sections where required. LWRC makes its own Skirmish flip-up sights from 7075-T6 aluminum. The rear sight consists of a square post that is lifted and then rotated to change aperture settings. The post is also serrated to reduce glare. The front sight consists of a square post that is adjustable for elevation and features a semi-circular guard that is reminiscent of the front sight on the HK MP5.

The IC-PDW features an 8.5-inch barrel with a proprietary four-prong flash suppressor. LWRC barrels, including the IC-PDW’s, are made from 41V45 steel alloy that is forged from an oversized barrel blank using high-pressure rotary hammers. This process results in near-perfect rifling that is molecularly stronger than other forms of rifling. The barrels on the IC-PDW are also treated with NiCorr, which is “more lubricious, harder wearing, and more heat and corrosion resistant than normal hard chrome.” The company advertises a barrel life of 20,000 rounds as compared to 6,000 to 10,000 rounds for standard mil-spec barrels.

As with other LWRC rifles, the IC-PDW runs on the company’s patented, self-regulating, short-stroke piston system. The design eliminates the gas and carbon buildup in the receiver and bolt carrier group, enhances reliability and reduces felt recoil and muzzle rise. It is important to note that, even with the piston system, the LWRC rifles retain 80-percent parts commonality with traditional direct-impingement rifles. The piston is accessed by loosening two retaining screws and removing the top portion of the rail assembly. The design captures the retaining screws and allows for easy maintenance in the field.

Advertisement — Continue Reading Below

The IC-PDW upper uses the same upper receiver as LWRC’s popular IC-PSD. The beefy ambidextrous charging handle provides a solid purchase when manually operating the action. To enhance reliability and service life, LWRC engineers replaced the standard buffer spring with a flat wire spring. This design requires both takedown pins to be pushed out to allow the upper to be separated from the lower receiver for disassembly.

The buffer tube extends a mere 3.5 inches from the rear of the receiver, whereas a standard M4 buffer tube is 6.5 inches in length. This design reduces the operating space for bolt travel by 46 percent! That detail alone should quantify the challenge of shortening the M4 to meet the DHS’ PDW requirements. The collapsible stock rides on two steel rails and, when released, extends the stock approximately 4.5 inches. The ribbed buttplate is machined from a solid piece of aluminum and provides a solid and stable mounting surface for firing.

Prior to hitting the range, I installed Aimpoint’s new Micro T-2 using a LaRue Tactical mount. The new T-2 offers improved lens coatings, light transmission and clarity while the new housing has protective wings for the elevation adjustment. The T-2 comes standard with flip-up lens covers that will make Micro users very happy. Like the T-1, the T-2 has eight daylight settings and four settings that are compatible with night vision. A single 3-volt lithium provides 50,000 hours of constant run time on a daylight setting. Finally, the new steel helicoil inserts for the mounting screws are less likely to be stripped and are easily replaced. The Micro T-2 is the next evolution in red-dot sights and is unsurpassed in terms of durability, functionality and battery life. For those not needing the night-vision capability, Aimpoint has just released the Micro H-2 for the sporting market.

Advertisement — Continue Reading Below

Given the small size and low profile of the IC-PDW, I elected to mount my SureFire Mini Scout light using S&S Precision’s IFM Rigid mount. This mount incorporates both a mounting clamp and the battery tube. To use the IFM mount, I simply attached the head and the rear switch plate from my Mini Scout. When mounted to the top Picatinny rail, the body of the light tucks neatly in the 11 o’clock position. Due to the short rail, I had to mount the light slightly to the rear in order for the head to clear the base of the front sight. This required bringing the support hand back to the front of the magazine well in order to access the rear switch. I did not find this to be an issue on a super-short SBR.

Range Time

On the range, the LWRC IC-PDW carbine was 100-percent reliable with a variety of commercial and military loads. I installed a Leupold 2.5-8x36mm Mark 4 tactical scope with a LaRue SPR mount for the 100-yard accuracy testing. Shooting from a bench and using the wire stock proved challenging, but it was not uncomfortable and didn’t beat up my face.

Advertisement — Continue Reading Below

I used three proven defensive rounds for testing: Hornady’s 55-grain TAP Urban and 62-grain TAP Barrier load as well as RUAG’s 62-grain Swiss P Styx Action round. The 55-grain TAP averaged 2,420 fps while the 62-grain Barrier averaged 2,279 fps. The RUAG averaged 2,446 fps. The IC-PDW lived up to my expectations and proved to be exceptionally accurate with all three loads. The 55-grain TAP produced a group that measured 1.35 inches while the 62-grain Barrier’s group measured 1.25 inches. The RUAG group opened up to a still very acceptable 2.10 inches.

The real fun came when I mounted the Micro T-2 on the IC-PDW and performed some quick drills with multiple rounds and target transitions. The key to shooting the IC-PDW is to have a positive cheekweld on the buffer tube, not the wire portion. When this position was used, the little rifle proved to be fast and accurate.

RELATED STORY: 6 Unique Rifles From LWRC International

The IC-PDW is well suited for protective details as well as close, confined environments, including inside vehicles. Being easily concealed, it is also ideal for high-risk undercover and surveillance operations for both the military and law enforcement communities. A select-fire model is available for qualified organizations. While I have several SBRs in my safe, the IC-PDW fills a niche that will make it hard to return. If you have a requirement for the ultimate compact AR, I recommend that you seriously consider the LWRC IC-PDW.

Advertisement — Continue Reading Below

For more information on the IC-PDW, visit lwrci.com or call 410-901-1348.