World War II heralded paradigm-shifting changes for the world that would emerge at the end of the conflict, both politically and militarily. Leading up to the massive conflagration, world powers worked to develop capable and effective small arms to fight what was the inevitable conflict. From ultra-modern submachine guns that could be produced more cheaply and employed very quickly, to refinements and enhancements of light machine gun designs that brought shatteringly effective firepower to the battlefield, World War II saw the introduction of influential weapon designs that would in many cases serve well beyond the deadly days of that colossal conflict. Read on to see our picks of the top 10 World War II guns:

World War II Guns — THOMPSON SUBMACHINE GUN: Battle and Movie Star

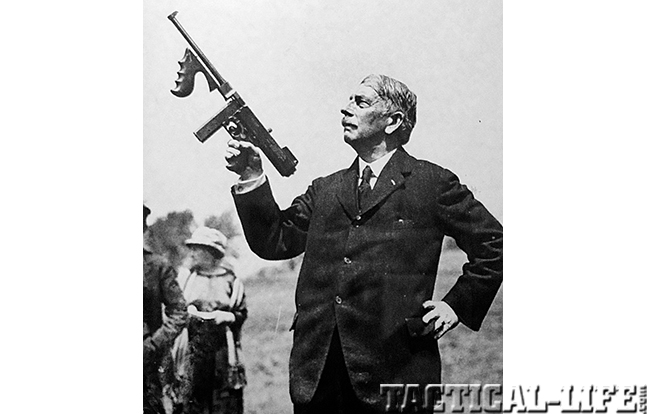

Model 1921 Thompson .45 ACP submachine guns first saw combat when they were carried by U.S. Marines in Nicaragua during the conflict known as The Banana Wars. In 1928, the U.S. Navy adopted a slightly modified version of the M1921 that included a slower rate of fire. In the years leading up to World War II, the U.S. Army also officially adopted a version of the Thompson called the M1928A1. Once the British began taking delivery of the Model 1928A1, the Thompson became known as the “Tommy Gun.”

The original Thompson was designed to operate using a detachable 50- or 100-round metal drum magazine or a 20-round metal box or “stick” magazine. One of the easiest ways to distinguish the M1928A1 from the M1 and M1A1 is the location of the cocking handle, which is positioned on the top of the receiver on the M1928 and the M1928A1, while the cocking or charging handle on the M1 and M1A1 is located on the right side of the receiver.

Advertisement — Continue Reading Below

Thompsons adopted by the military, officially standardized as the “United States Submachine Gun, Caliber .45, M1” and M1A1, were unable to use drum magazines and were expressly configured to accept 20- and 30-round stick mags. A plain barrel and the use of a stamped rear sight instead of an adjustable rear sight were also used on later models to cut production time and costs. Internal changes were also made to the M1 and the M1A1 models that involved the use of a straight-blowback operating system. Despite weighing over 11 pounds when loaded, the Thompson submachine gun was a very popular and sought-after weapon to carry in combat. Approximately 1.5 million Thompson submachine guns were manufactured.

SPECIFICATIONS: M1 THOMPSON SMG

CALIBER: .45 ACP

BARREL: 10.5 inches

Advertisement — Continue Reading Below

OA LENGTH: 32 inches

WEIGHT: 10.6 pounds (empty)

SIGHTS: Front blade, adjustable or fixed rear

Advertisement — Continue Reading Below

ACTION: Select-fire or full-auto

FINISH: Blued, Parkerized

CAPACITY: 20+1, 30+1

Advertisement — Continue Reading Below

RATE OF FIRE: 600-800 rpm

World War II Guns — M3 & M3A1 GREASE GUN: Thompson’s Replacement

The submachine gun officially designated the “U.S. Submachine Gun, Caliber .45, M3” was issued in mass to U.S. and certain Allied troops and resistance groups from 1943 to 1945. From design, production and cost perspectives, the M3 emulated the British Sten gun. Unlike the more complex and expensive Thompson submachine gun, the M3 and the M3A1 were manufactured by the Guide Lamp division of General Motors using stamped and welded metal parts and a few critical machined parts. A small number of 9mm versions were also manufactured for OSS Agents and resistance groups.

Advertisement — Continue Reading Below

The M3/M3A1 was commonly referred to as the “Grease Gun” because it looked like the famous mechanics’ tool that was used for lubricating vehicles. The M3/M3A1 was a blowback-operated submachine gun that fired from an open bolt and had a fixed firing pin. The M3 and M3A1 used 30-round metal box magazines that were not interchangeable with the Thompson’s. Unlike the faster-firing Thompson (600 to 800 rpm), the Grease Gun had a slower rate of fire of 450 rpm.

The M3 used a cocking handle lever that was positioned behind the top of the magazine well and below the ejection port. Once a loaded magazine was inserted into the magazine well and the cocking lever was cycled, the M3/M3A1 was fired by pulling the trigger on an open bolt. The M3A1 version eliminated the cocking handle and used two parallel indentations that were drilled into the surface of the bolt assembly to retract the bolt to the rear. To place the M3/M3A1 on “safe,” the operator closed the cover over the ejection port.

Over 600,000 M3s were produced during WWII. With the exception of some reliability problems that were caused by the single-feed design of the M3/M3A1 magazines, the Grease Gun generally served with distinction during WWII.

Advertisement — Continue Reading Below

SPECIFICATIONS: M3/M3A1 GREASE GUN

CALIBER: .45 ACP

BARREL: 8 inches

OA LENGTH: 23-30 inches

Advertisement — Continue Reading Below

WEIGHT: 8 pounds (empty)

SIGHTS: Fixed

ACTION: Full-auto

Advertisement — Continue Reading Below

FINISH: Parkerized

CAPACITY: 30+1

RATE OF FIRE: 450 rpm

World War II Guns — REISING M50 & M55: H&R-Built For USMC

During the early days of WWII, the U.S. Marine Corps adopted the Reising M50 and M55 .45 ACP submachine gun because there was a shortage of standard-issue Thompson submachine guns. The Reising operated from a closed bolt and used a delayed-blowback operating system that was manufactured using a number of machined parts.

While the Reising M55 was equipped with a wire folding stock, the M50 was manufactured with a wooden stock. Both models accommodated 12- or 20-round box magazines that were inserted into a magazine well in the underside of the receiver. Both variants had barrels that were 10.4 inches long. The M55 was not equipped with a barrel compensator.

Initially, the Reising M50 and M55 appeared to be worthwhile designs because they were manufactured using high-quality critical components, they were lighter and more compact than Thompson submachine guns, they were very accurate when fired on semi-auto, and they were less expensive to produce than the Thompson. Unfortunately, the tight tolerances between critical parts, as well as problems relating to corrosion and maintenance, resulted in reliability problems when the Reising M50 and the M55 were exposed to sand, dirt, debris, rain and humidity under combat conditions in a jungle environment. Approximately 100,000 Reising submachine guns were manufactured during WWII.

SPECIFICATIONS: REISING M50/M55

CALIBER: .45 ACP

BARREL: 11 inches

OA LENGTH: 31-38 inches

WEIGHT: 6.2-6.8 pounds (empty)

SIGHTS: Fixed

ACTION: Select-fire

FINISH: Blued

CAPACITY: 12+1, 20+1

RATE OF FIRE: 500-550 rpm

World War II Guns — BROWNING AUTOMATIC RIFLE: America’s Automatic

Because John Browning invented the famous Browning Automatic Rifle (BAR) during World War 1, the U.S. Armed Forces already possessed a proven, reliable squad automatic rifle when the U.S. entered WWII. In addition to being issued to U.S. personnel, BARs were also shipped to England as lend-lease weapons.

While the M1918 and the M1918A1 models were capable of semi- and full-auto fire, the M1918A2 BAR was configured to operate exclusively on full-auto. However, the M1918A2 BAR was also designed to allow the operator to adjust the rate of fire from 300 to 450 rpm or 500 to 600 rpm depending on the setting.

Due to the weight of an unloaded BAR (16 pounds for the M1918, 18 pounds for the M1918A1 and some 20 pounds for the M1918A2), plus the basic combat load of 12 20-round magazines, it was no easy task to carry a BAR in combat. As a result, when it was necessary to have immediate access to an additional supply of ammunition, an assistant BAR gunner carried extra loaded magazines. BAR gunners also often removed some or all of the accessories, such as the collapsible bipod and the carry handle, to lighten their BARs.

Two criticisms of the BAR involved the limited quantity of ammunition that was held in each magazine and the inability to quickly change barrels in the field. Even though these criticisms existed, the BAR had a well-deserved reputation for being rugged, reliable and accurate in combat. Several hundred thousand BARs served in combat during WWII.

SPECIFICATIONS: BROWNING AUTOMATIC RIFLE

CALIBER: .30-06 Springfield

BARREL: 24 inches

OA LENGTH: 47.9 inches

WEIGHT: 16-20 pounds (empty)

SIGHTS: Front post, leaf-type rear

ACTION: Select-fire, full-auto

FINISH: Blued

CAPACITY: 20+1

RATE OF FIRE: 300-650 rpm

World War II Guns — BROWNING M1919 MG: U.S. Medium .30 MG

One of the better-known American-made, belt-fed MGs used during WWII was the M1919. The M1919A4 was a recoil-operated, air-cooled, belt-fed, .30-06-chambered light machine gun with an 18-inch barrel that had a rate of fire of 400 to 550 rpm. In order to enable air to cool the M1919 under firing conditions, a ventilated shroud was installed over the barrel. Because the M1919 was air-cooled instead of water-cooled, the M1919 was lighter and easier for a machine gun crew to carry and use in combat. When equipped with a tripod to support infantry troops, the M1919A4 weighed just over 30 pounds. The M1919A4 was also mounted on vehicles and aircraft. Well over 300,000 M1919A4 belt-fed machine guns were manufactured during WWII.

In 1943, the M1919A4 was a modified to be capable of being operated by one soldier. The end result of this modification was the M1919A6, a 32-pound belt-fed machine gun that had a rate of fire of 400 to 500 rpm and was equipped with a wooden carrying handle, a lighter barrel, a removable wooden stock, a pistol grip, a folding bipod and a flash suppressor. Over 40,000 M1919A6s were manufactured during the war. The ANM2 was a modified M1919 that was initially used in U.S. combat aircraft. Modified versions of the ANM2 were lighter than the M1919A4 and had a much higher rate of fire.

SPECIFICATIONS: BROWNING M1919A4/M1919A6

CALIBER: .30-06 Springfield, 7.62x63mm

BARREL: 24 inches

OA LENGTH: 48-53 inches

WEIGHT: 31-32 pounds (empty)

SIGHTS: Adjustable rear aperture

ACTION: Full-auto

CAPACITY:Belt-fed

RATE OF FIRE: 400-600 rpm

World War II Guns — GERMAN MG34: Belt- Or Mag-Fed Beast

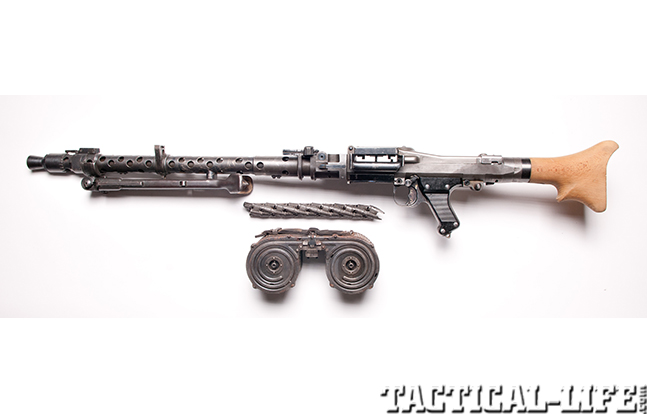

The German MG34 is an air-cooled, recoil-operated machine gun that could be used with different-length belts of non-disintegrating metal-linked ammunition, a metal basket drum that contained a 50-round belt of ammunition or a 75-round double drum magazine. The MG34 had a rate of fire of 800 to 900 rpm and an effective range of 2,000 meters. One of the most ingenious and useful design features of the MG34 was the ability to change barrels in the field without the need to bring the weapon to an armorer.

The MG34 was also equipped with a “crescent”-shaped trigger that enabled the gunner to depress the top portion of the curved trigger to fire single shots or depress the bottom portion of the curved trigger to deliver fully automatic fire. At 26.5 pounds unloaded, the MG34 was carried by one solider even though a two- or three-man team was usually assigned to operate the MG34. The MG34 was chambered in the same caliber (7.92x57mm) that used in Germany’s bolt-action battle rifles. All of these features made the MG34 a true modern marvel of the time.

Unfortunately, the MG34 was so well made it was difficult to mass-produce in a cost effective and timely fashion during wartime conditions because too many parts required machining. The MG34 was also constructed with tighter tolerances between critical parts, which contributed to gunners experiencing stoppages while operating in adverse conditions. Even though the MG34 wasn’t perfect, large numbers were effectively used until the end of WWII. Hundreds of thousands of MG34s served throughout the war and were also known to be captured and used by certain Allied forces, especially by the Russian troops, partisan forces and resistance groups.

SPECIFICATIONS: MG34

CALIBER: 7.92x57mm Mauser

BARREL: 24.7 inches

OA LENGTH: 48 inches

WEIGHT: 26.7 pounds (empty)

SIGHTS: Flip-up front and rear

ACTION: Semi-auto/full-auto

FINISH: Blued

CAPACITY: Belt-fed, 50-round drum, 75-round double drum

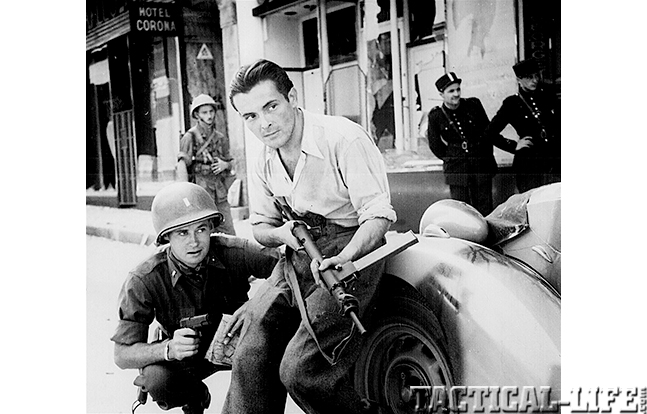

World War II Guns — BRITISH STEN: Royal Answer To Tommy Guns

Due to the growing demand to arm British, Commonwealth and resistance forces with a rugged submachine gun that was inexpensive to mass-produce, the British designed the 9mm Mark I Sten gun. The Sten gun gets it name by combining the names of the inventors and the manufacturer Sheppard, Turpin and Enfield. In addition to its trademark tubular receiver, the Mk I was fitted with a relatively thin triangular-shaped metal stock, while the Mk II was equipped with a straight metal tubular stock that was fitted with a flat metal buttplate. The 32-round, single-feed box magazine was loaded horizontally into the magazine well positioned on the left side of the receiver. The charging handle was positioned on the right side of the tubular receiver.

As the war progressed, certain refinements were made to original design of the Sten gun that resulted in the production of the Mk V and Mk VI models. (The Mk IV Sten was never mass-produced or issued.) Some of these refinements included the use of a wooden stock, a wooden pistol grip, a wooden vertical foregrip and the installation of rifle sights on the business end of the barrel. A suppressor was also installed on the Mk IIS and the Mk VI Sten. The fact that the Sten could be easily disassembled made it easy to airdrop to resistance fighters and maintain.

The British Sten gun proved to be a rugged submachine gun that generally performed well under adverse conditions. By the end of the war some 4 million Sten guns were produced. Of the five variants that saw combat, approximately half of all Sten guns were the Mk II model.

SPECIFICATIONS: STEN MK II

CALIBER: 9mm

BARREL: 7.7 inches

OA LENGTH: 30 inches

WEIGHT: 7.1 pounds (empty)

SIGHTS: Front post, fixed peer rear

ACTION: Full-auto

FINISH: Blued

CAPACITY: 32+1

RATE OF FIRE: 500 rpm

World War II Guns — BRITISH BREN: Infantry LMG

The British Bren gun was a reliable gas-operated, piston-driven modified version the Czeck ZB vz. 26 light machine gun that was converted to reliably chamber .303 British rifle ammunition. Fours variants of the Bren were produced during WWII. The Mark 3 was the lightest model with the shortest barrel. Minor changes in manufacturing and design were made to the different Bren models during WWII.

One of the most distinctive features of the Bren was the use of a curved box magazine that was loaded into the chamber through the top of the receiver. The Bren was the only light machine gun in an Allied army that was designed to enable the operator to easily change overheated barrels under combat conditions. The wooden carry handle aided in the barrel-removal process. Bren guns used a slightly offset sighting system to allow the gunner to engage targets when a loaded magazine was inserted into the top of the receiver. The Bren gun was also fitted with a folding bipod for stability while firing.

Even though the Bren could be operated in combat by one soldier, it was commonly operated by a crew of two, with additional British or Commonwealth soldiers carrying extra loaded magazines. In addition to be used by ground fighting units, Bren guns were also installed on vehicles and on anti-aircraft mounts. Throughout its service, the Bren maintained a reputation for reliability and accuracy while providing a rate of fire around 500 rpm at an effective range of 600 meters.

SPECIFICATIONS: BREN

CALIBER: .303 British

BARREL: 25 inches

OA LENGTH: 42 inches

WEIGHT: 22 pounds (empty)

SIGHTS: Offset, folding leaf or aperture rear

ACTION: Full-auto

FINISH: Black/Parkerized

CAPACITY: 30+1

RATE OF FIRE: 500-520 rpm

World War II Guns — RUSSIAN PPSh41: The Pe-Pe-Sha For CQB

With more than 5 million-plus copies made by 1945, the Russian Pistolet-Pulemyot Shpagina of 1941, or PPSh41, is believed to be the most mass-produced submachine gun of WWII. The PPSh41 was designed in 1940 and was issued in large numbers by 1942. Unlike other weapons of the time, the PPSh41 was produced rather quickly in various locations, from factories to workshops, using manufacturing methods that cut cost and limited the use of vital raw materials. Even the use of a heavy wooden stock limited the reliance on metal components to produce the PPSh41. The Russians also maximized the use of existing stockpiles of bolt-action rifles by producing PPSh42 barrels from surplus M1891 Mosin-Nagant barrels.

The PPSh41 was largely produced using metal stampings and featured a blowback operating system that included the use of a perforated cooling jacket around a chrome-plated barrel that was fitted with a compensator. It was used with a 71-round drum magazine and a 35-round curved magazine.

The PPSh41 was chambered in 7.62x25mm, which was the standard 86-grain bottleneck cartridge used in the famous Russian Tokarev pistol. The PPSh41 had a rate of fire of 900 rpm and was known to be incredibly reliable. Despite being issued in mass to Russian troops, numerous captured PPSh41s were also used by the German military. The Germans also converted a number of captured PPSh41s to operate with 9mm caliber ammunition. This conversion was known as the MP717.

SPECIFICATIONS: PPSh41

CALIBER: 7.62x25mm Tokarev

BARREL: 10.6 inches

OA LENGTH: 33.2 inches

WEIGHT: 8 pounds (empty)

SIGHTS: Hooded front, tangent rear

ACTION: Select-fire

FINISH: Blued

CAPACITY: 71-round drum, 35-round mag

RATE OF FIRE: 1,000 rpm

World War II Guns — RUSSIAN PPS: Red Army PDW

The one fact that makes the Russian Pistolet-pulemyot Sudaeva, or PPS, an amazing design is that this particular su machine gun was manufactured during the siege of Leningrad and was field-tested in actual combat. The PPS-42 and PPS-43 were constructed with a minimal number of machined parts (barrel and bolt assembly). Instead, stamped sheet metal parts were welded, riveted and pinned together.

The PPS operates using an open bolt with a fixed firing pin. A perforated cooling shroud was installed around the barrel to ventilate heat under firing conditions. A muzzle brake is also attached to the end of the barrel to help reduce muzzle climb. The PPS-42 was manufactured with a wooden stock, while the PPS-43 was equipped with a metal stock that folded over the top of the receiver. The PPS-42 and PSS-43 were also equipped with a wooden- or a plastic-covered pistol grip. Both models were also exclusively designed to be used with a 35-round metal box magazine.

The PPS-42 and the PPS-43 were chambered in the 86-grain bottleneck 7.62x25mm Tokarev service pistol caliber, and both had a rate of fire of about 650 rpm. Even though some number of PPS submachine guns were converted to operate in 9mm by the Germans, the bulk of the 1 million PPS guns were reliably used in the standard-issue Tokarev caliber.

SPECIFICATIONS: PPS-42/43

CALIBER: 7.62x25mm Tokarev

BARREL: 9.6-10.7 inches

WEIGHT: 6.5-6.7 pounds

OA LENGTH: 24-35 inches

SIGHTS: Fixed front blade, flip-up rear

ACTION: Full-auto

FINISH: Blued

CAPACITY: 35+1

RATE OF FIRE: 650 rpm