“Synergy” is defined as “mutually advantageous conjunction or compatibility of participants…” However, a much simpler definition is the old saying, “The whole is greater than the sum of its parts!” That is the perfect description of Kings River Custom and its PFG 1911.

The Kings River Custom PFG

KRC was formed in early 2024 by a core group of exceptional people who share a passion for the 1911 pistol. Each brings years of experience in all aspects of the 1911 world. From critical prep work to fitting and assembly to managing the business side of the house, every member of the KRC team is an all-star.

What makes KRC unique is that it is an employee-owned business. Every employee has ownership, from the CEO and gunsmiths to the marketing and sales team. It is this dynamic, combined with shared values, that sets KRC apart.

Advertisement — Continue Reading Below

The Phoenix Fighting Gun – PFG

I dislike terms such as “base gun” or ” entry-level model.” While the PFG is the lowest-cost pistol in the KRC lineup, its parts, fit, and finish are equal to those of its top-tier pistols.

The Phoenix Fighting Gun is a precision-built, single-stack 1911 designed for hard use. The name represents the journey and rebirth of the company’s founding owners.

Advertisement — Continue Reading Below

The PFG is a five-inch, Government model 1911 with a traditional barrel/bushing and recoil spring system. KRC offers the Phoenix in either carbon or stainless steel frames and slides. The standard finish on the PFG is Cerokote. However, other finishes, such as DLC, traditional blue, and color case are also available.

In addition, KRC offers several stock options, including G-10, ironwood, and mammoth ivory. The company also offers a full line of engraving options.

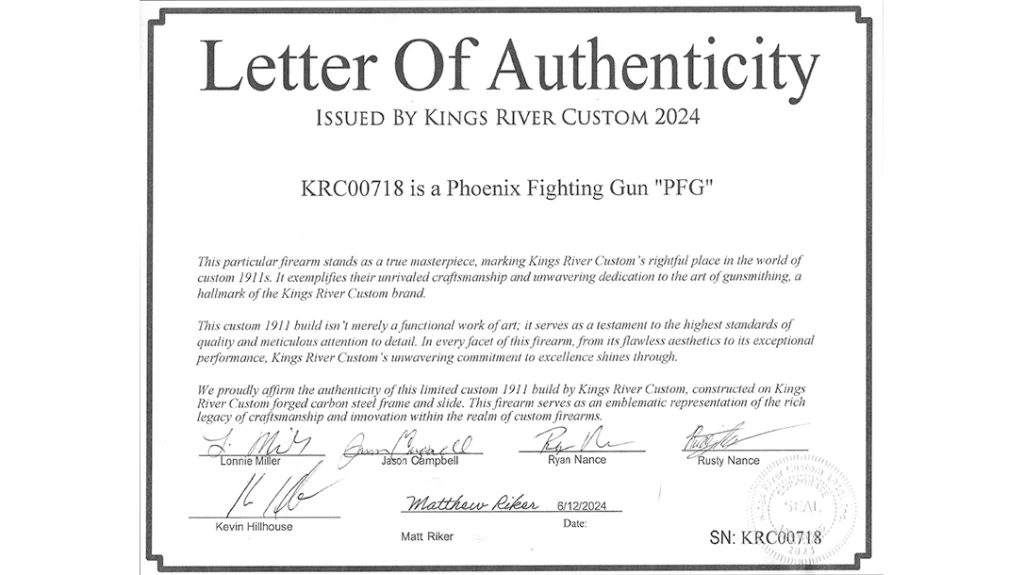

Our test pistol was shipped in a custom nylon case with a detailed build sheet, a signed test target, a warranty policy, and a customer satisfaction survey. The build sheet details the base features and any upgrades the customer may request. Finally, a letter of authenticity, which is specific to this gun, is included and signed by the employees.

Advertisement — Continue Reading Below

It is clear that each KRC owner/employee takes pride in and ownership of their work. The final sentence of the certificate states, “This firearm serves as an emblematic representation of the rich legacy of craftsmanship and innovation within the realm of custom firearms.”

A Positive Initial Impression

An initial examination of the pistol was very positive. The slide features eight cocking serrations that are widely spaced and are both functional and attractive. Additionally, it has been beveled, removing any offending sharp edges, and the ejection port is relieved to ensure reliability.

Advertisement — Continue Reading Below

The rear of the slide is perfectly blended with the rear of the frame, and the extractor is blended with the slide. The ball-end mill cuts are a classic modification that adds a degree of elegance to the pistol. Our test gun was set up with an optional silver bead in the front sight and KRC’s fixed rear sight.

The frame featured 25 lpi checkering on the front strap and the mainspring housing. The front strap is undercut at the base of the trigger guard to provide a higher purchase. A one-piece mainspring housing/magazine well is perfectly blended to the base of the frame.

Advertisement — Continue Reading Below

The beavertail grip safety was properly timed and fitted with only a small amount of lateral play. The trigger is an aluminum, 3-hole design, with an adjustable overtravel stop. Using my Lyman electronic trigger gauge, the PFG’s trigger broke cleanly at 3 lbs. 6 oz. with no over-travel.

I appreciated the minimal markings on the gun. The only marking on the slide is a Phoenix logo that is located on the right side, behind the cocking serrations. Other than that, the slide is void of any markings.

Advertisement — Continue Reading Below

The frame only has the required manufacturer’s identification information and serial number. The gun was finished in an optional DLC, and the standard G-10 stocks were upgraded to a set of gorgeous stabilized, high-figure, desert ironwood panels made by SK Grips.

Finally, each KRC 1911 comes standard with three Tripp Research Cobra eight-round magazines.

The PFG 1911 In Depth

I dropped by John Harrison’s shop and asked him to give the PFG a complete inspection. John is a renowned 1911 gunsmith and custom builder. I knew he would notice things that I had not seen.

He completely disassembled the PFG and went through it with a 10X loop, a set of calipers, and a sharp eye. John was impressed with the overall fit and finish. He specifically pointed out how nicely the chamber, feed ramp, and muzzle were contoured and chamfered.

John checked the extractor tension and fit, the barrel’s outer diameter, the bushing’s inside diameter, and other critical fit areas. He also took particular notice as to how well the sear and hammer engagement was. The PFG passed his inspection without any issues.

Range Evaluation & Observations

As is my habit, when evaluating a new pistol, I gathered a large sampling of different .45 ACP loads. The ammo ranged from standard 230 gr. ball to Black Hills 135 grain HoneyBadger load.

I ran my normal 1911 testing protocol with each load. This included chambering the two rounds from the full magazine from slide lock and feeding the last two rounds in the magazine to ensure slide lock on an empty magazine. I also tested the ejection pattern by firing ten rounds without a magazine in the pistol. The Cobra magazine also performed without issue.

The chart below reflects the velocities and my off-hand groups shot from 15 yards. Certainly, the pistol’s accuracy far exceeded my skills. Still, the PFG shot very well, and the ergonomics of the 1911 certainly helped my groups.

The PFG vs Ballistic Gel

I had a block of Clear Ballistics 10″ gel on hand and shot one round of each load into bare gel. However, time and ammo did not allow for a full test protocol.

Federal HST, when shot into bare gel, penetrated an average of 12” and expanded to an impressive .91”. The Federal Punch and Speer G2 expanded to .70” and .71”, respectively, and both penetrated to around 15”.

The most impressive expansion came from the Gorilla Silver Back, solid copper hollow point, which expanded to 1.25” in diameter and penetrated to 9.5”. Finally, the Black Hills HoneyBadger penetrated 15” with no expansion.

I also ran a modified “Test” where I drew from a holster and fired 8 rounds from 10 yards in 10 seconds. The drill is shot on a B-8 repair center and scored according to the value rings on the target. I managed to shoot a 90% with several shots going low into the “8” and “7” ring. Not my best run, but an acceptable score.

I really appreciated the great trigger and excellent sights of the PFG. I found the silver bead front sight easy to acquire and track under recoil. The undercut front strap and the fit grip safety allowed for a good purchase and recoil control.

The SK Grips ironwood stocks are slightly thicker than some 1911 stocks, but they filled my hands nicely.

Running the PFG at Speed

When I ran the PFG at speed, I found a couple of minor issues. The first is the magazine release spring is very stiff and made positive magazine ejection difficult. Since the magazine release is an extended length, I am assuming the KRC used an extra power spring.

The second issue is that the shelf of the slide stop is very narrow. There were several reload drills where the thumb slipped off the slide stop when attempting to drop the slide on a fresh magazine. I would like to see a wider shelf that is closer to the width of the thumb safety.

The PRG comes standard with a traditional coil mainspring that feels like an 18 lb. spring. While this was the preference for many years, I have come to prefer a 16 lb. spring that softens the recoil cycle. This is personal preference and not a criticism of the PFG.

Each of these observations is purely subjective, and many shooters may have the same experience as I did.

Moving Forward

In speaking with KRC CEO Matt Riker, I learned that my test pistol was an earlier gun, and there have been ongoing improvements in the Phoenix Fighting Gun. Since my pistol was built, the company has changed vendors for the DLC coating.

Another change is that newer pistols will have a flush-cut slide stop pin. They are also working with SK Grips to improve the contour of the stocks where they interface with the magazine well. They have also continued to expand the options available to include engraving and a number of premium finishes.

Closing Thoughts

We put close to 500 rounds through the KRC PFG, with zero issues. Knowing the people involved and their expertise and commitment to quality, I was not surprised. KRC is continuing to build out its dealer network and marketing objectives while turning out quality pistols.

What will not change is the core principles and commitment to quality. I look forward to watching the company “take flight” and seeing what the future holds.

For more information, please visit KingsRiverCustom.com.

Kings River Custom PFG 1911 Specs

| Caliber | .45 ACP |

| Slide & Frame | Carbon Steel |

| Finish | Optional DLC |

| Safety | Single Side |

| Barrel | 5” Match Grade |

| Front Sight | Dove Tail/Silver Bead |

| Rear Sight | KRC Fixed Black |

| Magazines | 3 Cobra 8-round Magazines included |

| MSRP | $5,090 |

Performance

| Manufacturer | Load | Velocity | Accuracy |

| Gorilla Silver Back | 135 gr. Fluted Solid Copper | 1,313 | 2” |

| Federal HST | 230 gr. JHP | 877 | .85” |

| Federal Punch | 230 gr. JHP | 850 | 1.25” |

| Federal Syntech Defense | 205 gr. SHP | 946 | 1.75 |

| Gorilla Silver Back | 230 gr. SCHP | 821 | .81” |

| Speer G2 | 230 gr. GDHP | 895 | 1.30” |

| Velocity measured from 10 ft./Accuracy Off-Hand 15 yds. | |||